SLLA636A June 2024 – August 2024 TCAN3403-Q1 , TCAN3404-Q1

1 Introduction

With the electrification of vehicles happening at a rapid pace, multiple ECUs are deployed all through the vehicle. These subsystems talk to each other through a CAN network.

Figure 1-1 shows a CAN network.

Figure 1-1 Typical CAN Network

Figure 1-1 Typical CAN NetworkEach CAN node consists of at least three components: a CAN transceiver, a microcontroller (MCU) or microprocessor (MPU), with an embedded CAN protocol controller and a power device (a DC/DC converter or linear regulator) that converts the automotive battery voltage to 5V. Additionally, in case the MCU or MPU’s input/output (I/O) voltage is 3.3V, a separate 3.3V power device is used on the ECU’s printed circuit board (PCB). Figure 1-2 shows a simplified schematic.

Figure 1-2 Application Schematic of a 5V

CAN Transceiver

Figure 1-2 Application Schematic of a 5V

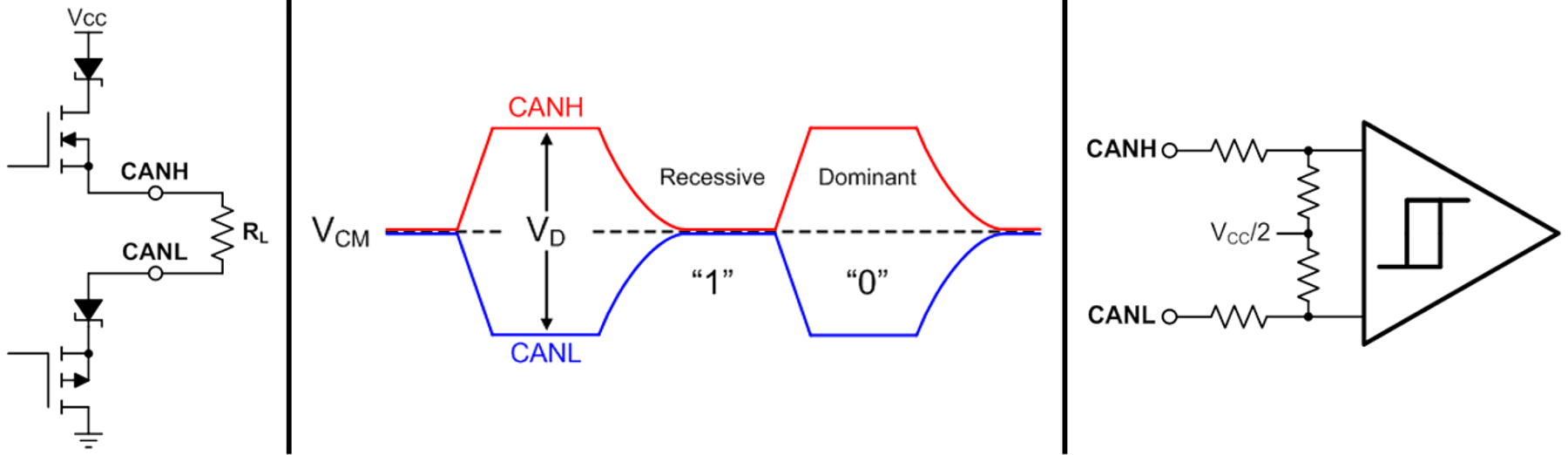

CAN TransceiverTypical CAN bus signals consist of dominant and recessive phases. A CAN driver produces a differential signal of at least 1.5V across a 60Ω load during the dominant phase, whereas the driver weakly biases the bus to a common-mode 2.5V level during the recessive phase. This signaling is designed for bitwise arbitration, and the device with the highest priority ID (the CAN frame identification field with the most dominant bits) takes control of the bus, since the dominant (strong) drive is able to overcome recessive (weak) biasing. The receiving nodes monitor CAN high and CAN low differential signals and can decode the CAN message as long as the signal is above 900mV (the dominant threshold) or below 500mV (the recessive threshold).

Figure 1-3 CAN Signaling, Diver and

Receiver Representation

Figure 1-3 CAN Signaling, Diver and

Receiver RepresentationVD = VCANH – VCANL

For driver: VOD(DOM) ≥ 1.5V @ 60 Ω load

For receiver: VID(DOM) ≥ 900mV, VID(rec) ≤ 500mV

A CAN wiring harness is spread throughout the vehicle. Any common-mode disturbance generated by the CAN transceiver can result in emissions that can impact the functionality of other automotive subsystems. Similarly, the harness is susceptible to electromagnetic interference from other modules. Thus, electromagnetic compliance is an important requirement for any automotive CAN transceiver. Different subsystems can have CAN transceivers from different semiconductor vendors; thus, interoperability is another requirement for any CAN transceiver to be used in a mainstream vehicle network.