SLLU374 November 2024 MCF8329A

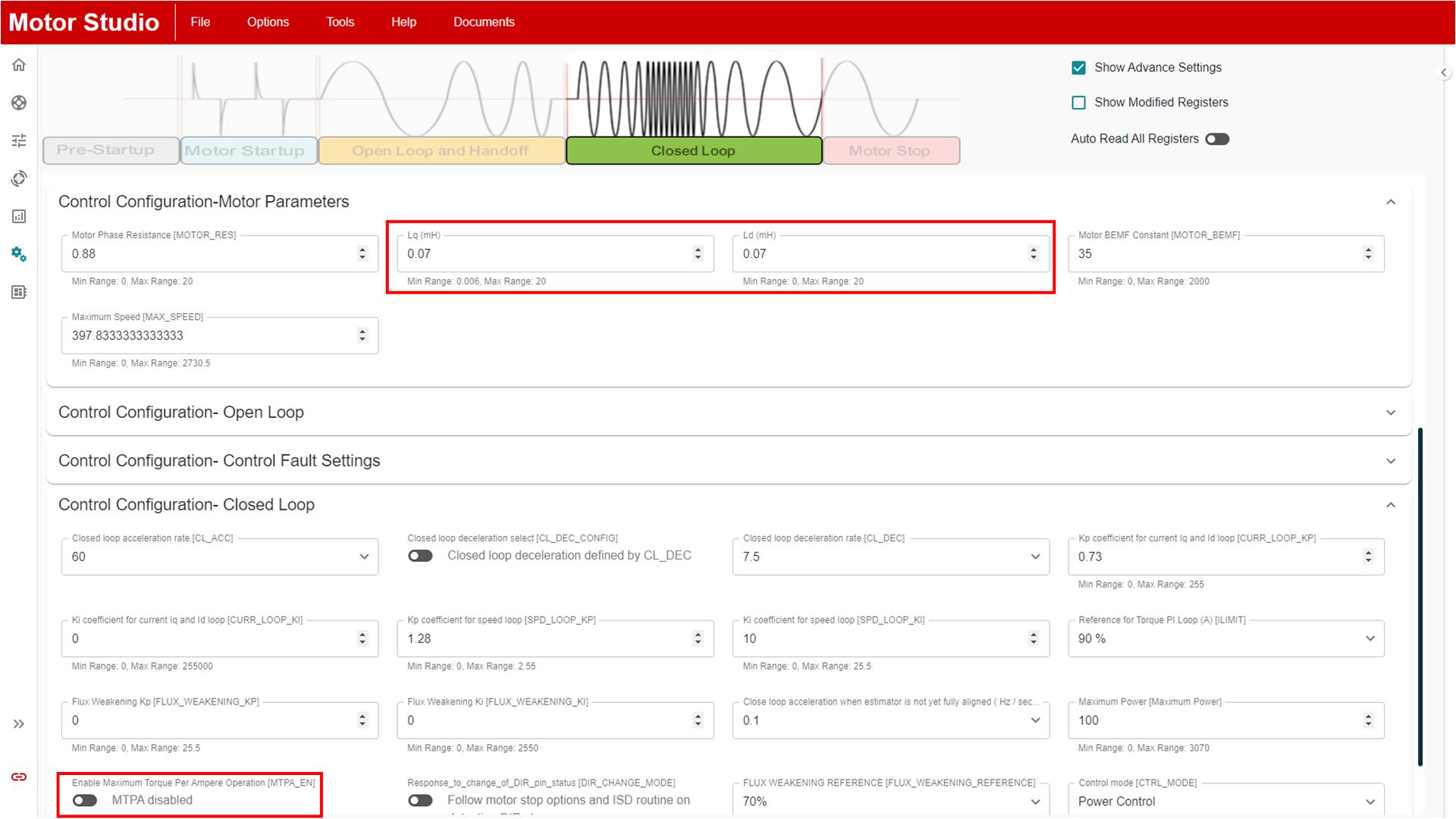

5.6 MTPA Tuning

Maximum torque per ampere (MTPA) is a feature in the MCF8329A to maximize the torque generated per ampere of current for salient motors. To enable MTPA, set MTPA_EN to 1b and set the SALIENCY_PERCENTAGE to a non-zero value by setting the Lq and Ld values if they are provided in the device-specific data sheet.

Figure 5-6 MTPA Settings

Figure 5-6 MTPA SettingsNote: If the motors Ld or saliency percentage is not known, the

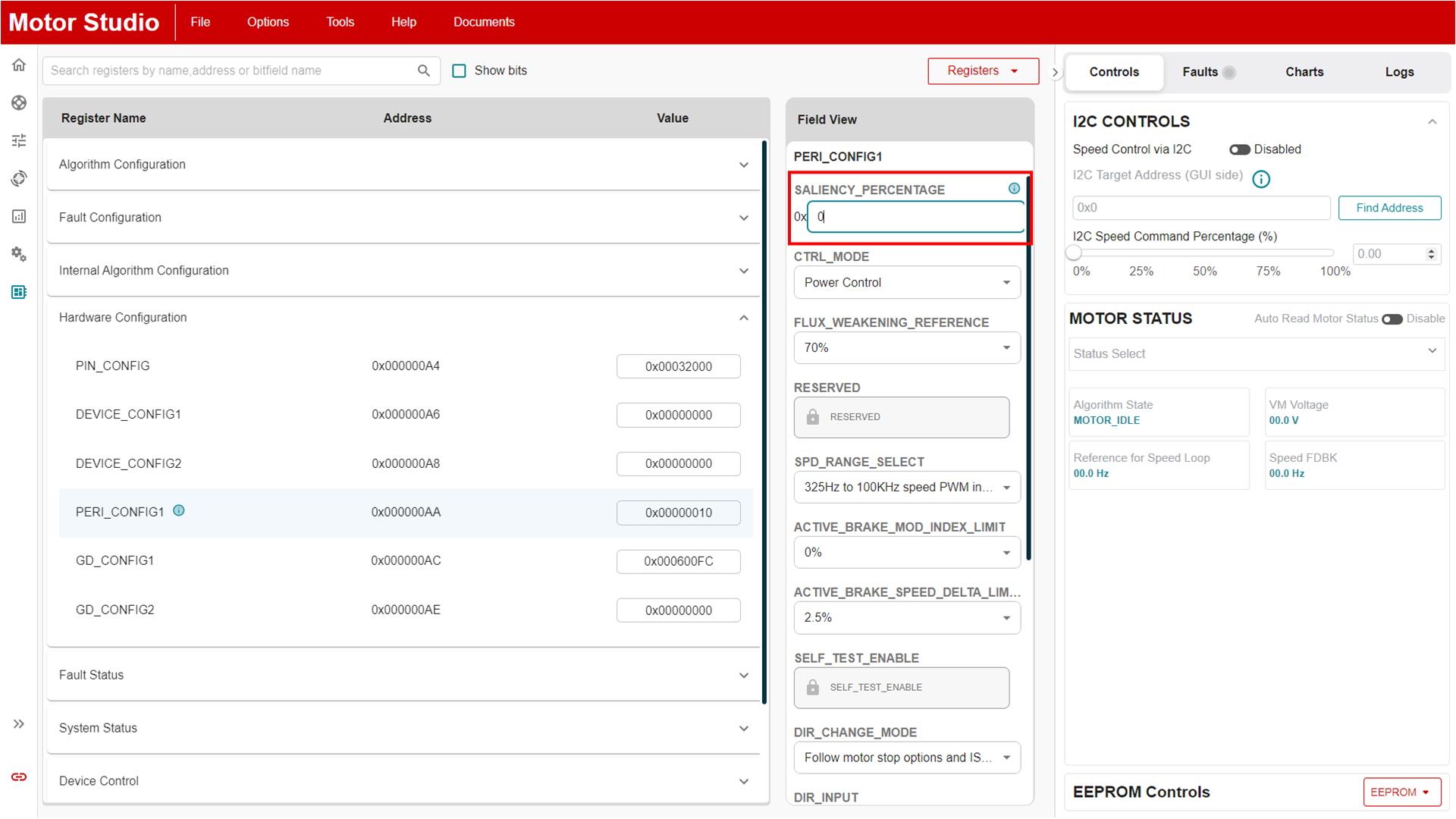

approximate SALIENCY_PERCENTAGE can be determined by following the steps below:

- Set the SALIENCY_PERCENTAGE to 0x1h

- Set the CTRL_MODE to Current Control mode

- Provide a speed command.

- While the motor is spinning, increment the SALIENCY_PERCENTAGE value by 1h until the motors speed begins to decrease.

Figure 5-7 Saliency Register

Figure 5-7 Saliency Register