SNAA398 September 2024 LMP91050 , LMP91051 , MSPM0G1506

Abstract

This technical article dives into the new A2L standards for residential and commercial HVAC systems and some of the system changes required to meet this standard. A2L refrigerants are refrigerants that have a lower global warming potential (GWP). This paper details current pertinent legislation, industry trends, technical operation of Non-Dispersive Infrared (NDIR) and metal oxide semiconductor (MOS) sensors, and the feasibility of various designs.

A2L Refrigerants Overview

A2L refrigerants are named from the ASHRAE safety classification and are mildly flammable, low toxicity, and low global warming potential (GWP). These refrigerants also have a zero-ozone depletion potential (ODP). As far as the chemical makeup of these refrigerants, A2L refrigerants are hydrofluoroolefins (HFO) or a blend of HFOs. Compared to previous HFC and HCFC refrigerants used in HVAC systems, namely R-410A and R-22 among others, the A2L refrigerants are more energy efficient while also conforming to greener energy initiatives worldwide. Table 1 below shows some common HVAC refrigerants along with the respective GWP/ODP values.

| Refrigerant | Type | GWP | ODP |

|---|---|---|---|

| R-22 | HCFC | 1820 | 0.055 |

| R-410A | HFC | 2088 | 0 |

| R-134A | HFC | 1430 | 0 |

| R-1234YF | HFO | 4 | 0 |

| R-1234ZE | HFO | 6 | 0 |

| R-32 | HFC | 675 | 0 |

| R-454B | HFC | 466 | 0 |

The drawback to A2L refrigerants is the inherent mild flammability associated with the chemical makeup, which means there are equipment manufacturer regulations needed to mitigate any dangerous situations where the refrigerant can combust given an ignition source. Figure 1 below shows a breakdown of different types of these refrigerants along with ignition and combustion data.

Figure 1 HVAC Refrigerant Combustion and Propagation Diagram

Figure 1 HVAC Refrigerant Combustion and Propagation DiagramA2L-Based Systems and the Additional Required Electronics to Comply With UL 60335-2-40

To maintain safe operation, air conditioning equipment features special components, such as refrigerant detection systems (RDS), as per safety standard UL 60335-2-40. RDS detects specific refrigerants and upon exceeding predefined thresholds, triggers mitigation actions like activating fans to dilute refrigerant concentration. Requirements for the RDS include:

- The leaking gas shall not exceed 25% of the LFL.

- The leaking gas shall not exceeding 15% of the LFL for a period of five minutes after the RDS has reset.

- Refrigerant detection system shall make output within 30 seconds of direct exposure to 25% LFL.

RDS devices typically consist of sensing elements, calibration for specific refrigerants, and interfaces for communication with HVAC equipment. These factory-installed systems are designed to last 10 to 15 years and undergo regular self-tests to maintain reliability. These RDS devices are crucial in preventing hazardous refrigerant leaks and highlighted various sensing technologies such as non-dispersive infrared, compact metal oxide sensors, and molecular property spectrometers being used in A2L detection. The deployment of RDS and adherence to safety standards are critical steps in the industry's response to regulatory changes.

The detection of lower flammability limit must meet or be kept below the values shown below in the second row of Table 2.

| Refrigerant | R-32 | R-454B | R-1234YF |

|---|---|---|---|

| Safety Group | A2L | A2L | A2L |

| LFL | 14.4% | 11.8% | 6.2% |

| Auto Ignition Temperature | 648°C 1198.4°F | 496°C 924.8°F | 405°C 761°F |

| Minimum Ignition Energy | 30-100 mJ | 100-300 mJ | 5000-10000 mJ |

| Burning Velocity | 6.7 cm/s | 5.2 cm/s | 1.5 cm/s |

| Heat of Combustion | 3869 Btu/lb | 4420 Btu/lb | 4408 Btu/lb |

A2L Refrigerant Leak Sensor Technology Overview

There are several types of A2L refrigerant leak detection sensors currently available in the market that comply with the UL 60335-2-40 standard. These sensors are typically implemented with NDIR or MOS technologies, each having respective advantages and disadvantages. The following section provides an overview of these technologies and the pros and cons of each.

NDIR Gas Sensor Overview

NDIR sensors, or non-dispersive infrared spectroscopy analyzes the concentration of a target gar based on the gases unique infrared light absorption. These sensors typically have some type of analog front end associated with them to provide a bandpass filter for the selected gas. As the IR light passes through the sampled gas, the gas absorbs the specific band of IR light while allowing the other wavelengths pass through. The detector then analyzes the remaining amount of light and based on a match between the missing IR band and the IR band at the detector, the sensor can decipher whether the gas is present or not. The advantage to this technology is the high selectivity and the detection accuracy, but the size of these sensors and the cost associated with them can be a drawback for this particular sensor type. These sensors are also susceptible to mechanical vibration, which can cause changes in the output from the sensor, as well as sensor response reduction in polluted environments when exposed for long periods of time which causes particulate accumulation on the optical components.

Basic Structure: The NDIR sensor contains an IR light source, usually a small lamp or an LED, which emits broad-spectrum infrared radiation. The IR light passes through a chamber filled with the gas sample. Positioned after the sample chamber, an optical filter allows only the specific wavelength of IR light that the target gas absorbs to pass through. The detector (the thermopile) then measures the intensity of the filtered IR light after the light passes through the gas sample.

The NDIR sensor also commonly contains a reference thermopile. The reference thermopile is used to monitor any variation of IR source output due to source aging and power variations, allowing for much more acurate gas sensing. Figure 2 below shows a basic NDIR sensor in addition to the AFE which is used for signal conditioning before reaching the ADC for further processing.

Figure 2 Basic NDIR Sensor Architecture Example

Figure 2 Basic NDIR Sensor Architecture ExampleTheory of Operation: Each type of gas absorbs IR light at specific wavelengths. When the IR light passes through the gas sample, molecules of the target gas absorb light at these characteristic wavelengths. The more gas present in the chamber, the more IR light is absorbed, leading to a reduction in the light intensity that reaches the detector.

The detector measures the intensity of the IR light that passes through the gas. This intensity is inversely proportional to the concentration of the target gas; the less light that reaches the detector, the higher the concentration.

Once the signal is acquired by the ADC, the MCU begins the post-processing to extract the target gas concentration for a particular sample. The sensor electronics process the signal from the detector to calculate the concentration of the gas using the Beer-Lambert law. Shown in Figure 3, the Beer-Lambert law relates the gas concentration to the molar absorptivity of light at the peak absorption frequency of the desired gas, and the path length of the light through the gas. The left side of the equation is a ratio of intensity from the NDIR lamp to the intensity seen by the thermopiles. The right side includes constants for attenuation, length, and finally concentration.

Once the equation is arranged for concentration (c), this value can be entered into the gas law to output a ppm value. Depending on the desired threshold set by the designer and regulations, the sensor module MCU alerts the mitigation board in the event mitigation tasks need to occur.

The reference thermopile output is subtracted from the target gas thermopile, and when no target gas is present, the readings are the same and the output is zero. An amplification factor of 2000 is applied to get the millivolt signals into +/-2 volts range. The inverse Beer Lambert Law then uses the voltage converted to intensity values based on the thermopile data sheet. Using physical properties and geometry such as length and attenuation constant, the concentration is found. The best gas law considers the pressure and temperature to produce a final calculation in parts per million of the given thermopile readings.

MOS Gas Sensor Overview

MOS sensors, or metal oxide semiconductor sensors work on the principle that the resistivity of certain semiconductors increases or decreases in response to surface interactions between the semiconductor and a particular gas. These sensors can not only detect a target gas, but can also estimate the concentration of that gas as well. The disadvantage to these sensors is susceptibility to cross-sensitivity with various chemicals such as gasoline exhaust fumes, propane, and others. These sensors can also experience drift associated with ambient conditions and thus, requires regular recalibration.

Basic Structure: The core of the MOS gas sensor is a thin film of a metal oxide, such as tin dioxide (SnO₂), zinc oxide (ZnO), or titanium dioxide (TiO₂). This material acts as the sensing layer. The sensing layer is typically deposited on a substrate, which can be silicon or a ceramic material. Two electrodes are placed on the sensing layer to measure the electrical resistance based on the gas molecule reactions. Figure 3 shows an example structure of a MOS-based gas sensor.

Figure 3 MOS Gas Sensor Diagram

Figure 3 MOS Gas Sensor DiagramTheory of Operation: At a specific temperature, the metal oxide in the sensor has a baseline electrical resistance, which is influenced by the oxygen molecules adsorbed on the surface of the metal oxide. These oxygen molecules capture free electrons from the conduction band of the metal oxide, forming a depletion layer that increases the resistance.

When the sensor is exposed to a target gas, the gas molecules interact with the adsorbed oxygen on the surface. This interaction can cause one of two main reactions:

- Reducing Gases (for example, CO, H₂, CH₄) donate electrons to the metal oxide surface, which reduces the amount of adsorbed oxygen and thus decreases the resistance of the sensor.

- Oxidizing Gases (for example, NO₂, O₂) can increase the amount of adsorbed oxygen, leading to an increase in resistance.

The sensor typically operates at elevated temperatures (200°C to 400°C), achieved by an integrated heater, to promote the necessary chemical reactions.

A2L Gas Sensing Technology Comparison Table

Table 2 below provides a summary of key characteristics of each type of sensor along with the advantages and disadvantages of both implementations. Other implementations not detailed above are heated diode and MPS detection.

| Specification | NDIR Sensor | MOS Sensor |

|---|---|---|

| Refrigerants Detected | CFC, HFC, HCFC, HFO | CFC, HFC, HCFC, HFO |

| Measurement Range | 0 to 10,000ppm | 20 to 10,000ppm |

| Response Time | < 10 seconds | 15 to 90 seconds |

| Humidity Range | 0 to 100% RH | 0 to 95% |

| Lifetime | about 10 to 15 years | about 3 to 5 years |

| Advantages | High selectivity Detection accuracy | Lower cost |

| Disadvantages | Size and Cost | Some false triggering from gasoline, diesel, propane |

Example Sensor Module Design For A2L Refrigerant Leak Detection Applications

There are several key systems requirements that must be met for compliance with UL 60335-2-40 with respect to the sensor module. The following section outlines these key features along with some of the device and system designs TI offers to meet these requirements.

Example refrigerant leak detection sensor module design:For the example sensor module, the NDIR-based technology is selected due to the popularity in the market and the advantages of using this technology.

The example A2L sensor module shown in Figure 4 is to use a packaged NDIR sensor which also includes the thermopile, gas chamber, and the NDIR lamp. The analog front end is created through active filters on both the reference and target gas thermopile side. The gas law and Beer-Lambert law are used together in software on the MCU to define a concentration from the given thermopile values. A threshold corresponding to the UL standards determines whether mitigation actions need to be taken

The part numbers selected for the design are shown below:

- MSPM0L1106 - MCU

- TLV2387 – AFE Amplifier

- THVD1500 – RS-485 Transceiver

Figure 4 A2L Gas Sensor Module Block

Diagram

Figure 4 A2L Gas Sensor Module Block

DiagramThe NDIR lamp is controlled by a GPIO pin from the MCU to enable and disable the lamp with a simplistic, low-cost method. The two thermopile readings are connected to the ADC of the microcontroller with the option to have an external ADC for higher resolution if desired. The analog front-end can be further simplified by using an optional LMP9105x AFE device.

Sensor Module Device Selection Guide

NDIR Sensor AFE: For NDIR type sensors, a bandpass filter is used to adjust the detection band to the target gas range. MOS sensors can also have some type of analog front-end to buffer the output from the sensor before going to the ADC. TI has several analog front-ends that are specifically for gas sensing applications such as NDIR.

- Fully Integrated AFE Device Selection: The LMP9105x family is a 1-2 channel configurable AFE for NDIR Sensing Applications. The LMP9105x device is a programmable integrated Sensor Analog Front End (AFE) optimized for thermopile sensors, as typically used in NDIR applications. The LMP9105x provides a complete signal path design between a sensor and microcontroller that generates an output voltage proportional to the thermopile voltage. The programmability of the LMP9105x devices enables the device to support multiple thermopile sensors with a single design as opposed to the multiple discrete designs.

Figure 5 LMP91050 Block Diagram

Figure 5 LMP91050 Block Diagram Figure 6 LMP91051 Block Diagram

Figure 6 LMP91051 Block DiagramThe LMP9105x family of devices also has the advantage of an accompanying EVM GUI that the designer can use to evaluate the performance of the AFE on the fly. This software is available on TI.com here.

- Discrete AFE device selection: If the designer chooses to go with a lower-cost discrete design for the AFE, the amplifier selection plays an important role for the overall performance of the sensor module. For this reason, a low noise, high precision amplifier is chosen for the discrete AFE option. The TLVx387 precision amplifier family offers many key features for sensor AFE amplifiers. With zero-drift technology, the TLVx387 offset voltage and offset drift provide unparalleled long-term stability. With a mere 570µA of quiescent current, the TLVx387 can achieve 5.7MHz of bandwidth, a broadband noise of 8.5nV/√Hz, and a 1/f noise at 177nVPP. These specifications are crucial to achieve extremely high precision and no degradation of linearity for interfacing to ADCs. The TLVx387 feature flat bias current over temperature; therefore, little to no calibration is needed in high input impedance applications over temperature.

Figure 7 TLV387 Precision Low-Noise ADC Driver

Example Circuit

Figure 7 TLV387 Precision Low-Noise ADC Driver

Example CircuitSensor Module MCU Selection

The MCU for the sensor module is responsible for several key processes within the RDS. This includes periodic testing of the sensor to maintain that the sensor is operating as expected, AFE signal aggregation (either interfacing to the internal ADC, or through I2C/SPI for discrete ADC applications), post processing, and communication back to the mitigation board.

Cost is another key consideration for the sensor module MCU selection, so for this design the MSPM0 device was chosen. There are quite a few devices in the MSPM0G, MSPM0C, and MSPM0L family that can work in this application.

- The MSPM0G3507 has two 12-bit SAR ADCs that allow for simultaneous sampling of the target and reference thermopile AFE outputs

- A lower cost MSPM0L110x series can be used in sensing architectures where only a single ADC is required

- If performance is not a key concern, the MSPM0C110x can be used for an even lower-cost sensor module MCU.

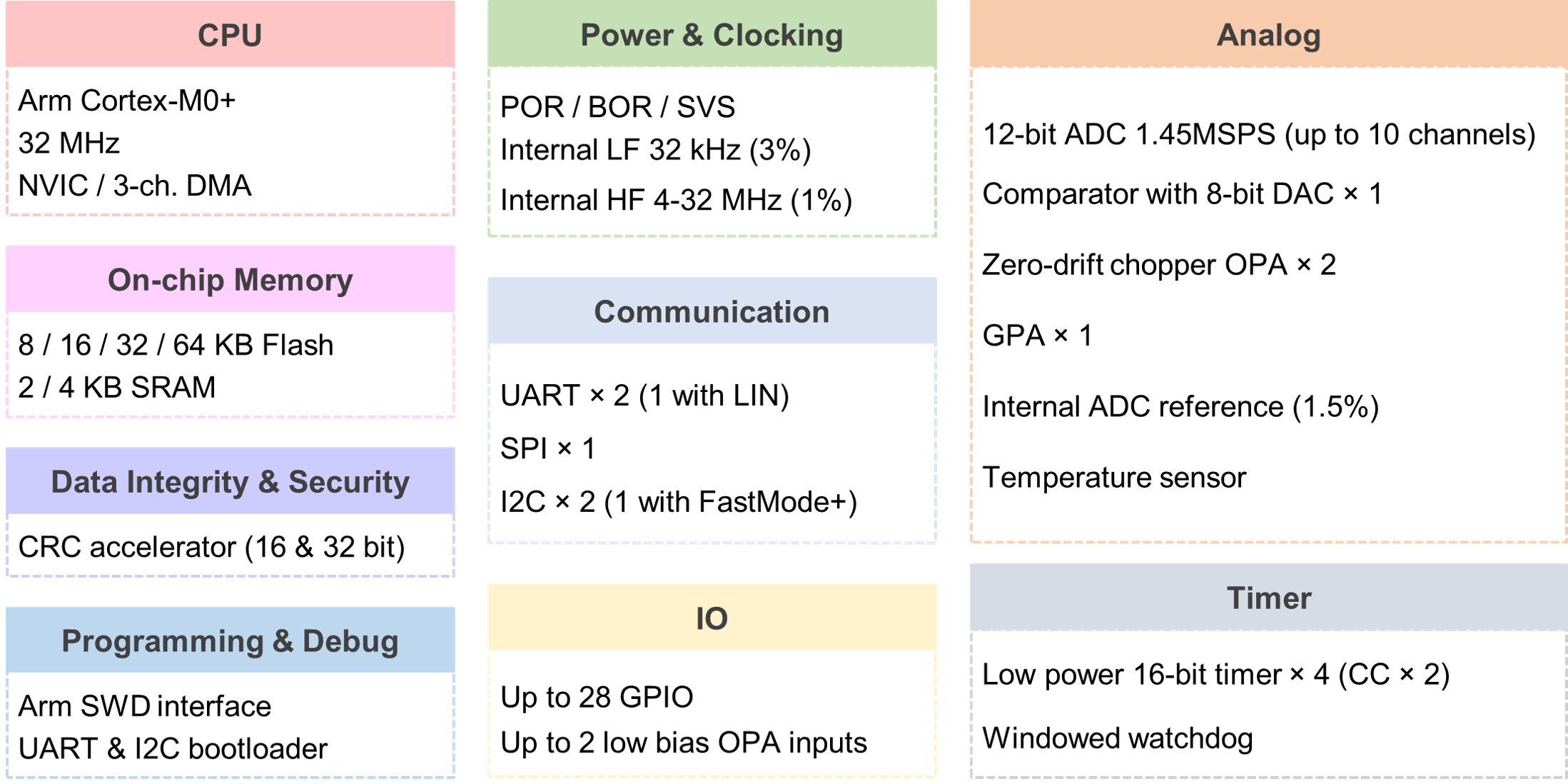

Figure 8 MSPM0L1106 Device Features

Figure 8 MSPM0L1106 Device FeaturesFor this design proposal the MSPM0L1106 is chosen as a good balance between performance and cost. The MSPM0L1106 provides 64KB embedded flash program memory with 4KB SRAM. These MCUs incorporate a high-speed on-chip oscillator with an accuracy up to ±1.2%, eliminating the need for an external crystal. Additional features include a 3-channel DMA, 16 and 32-bit CRC accelerator, and a variety of high-performance analog peripherals such as one 12-bit 1.68-Msps ADC with configurable internal voltage reference, one general-purpose amplifier, and an on-chip temperature sensor. These devices also offer intelligent digital peripherals such as four 16-bit general purpose timers, one windowed watchdog timer, and a variety of communication peripherals including two UARTs, one SPI, and one I2C. These communication peripherals offer protocol support for LIN, IrDA, DALI, Manchester, Smart Card, SMBus, and PMBus.

Sensor Module Communication Interface Selection

The sensor communication interface can vary from product to product, but RS-485 is a very common sensor module output, so RS-485 was selected as the target communication protocol. The THVD1500 is a cost optimized, robust half-duplex RS-485 transceiver for industrial applications. The bus pins are immune to high levels of IEC Contact Discharge ESD events eliminating need of additional system level protection components. The device operates from a single 5V supply. The wide common-mode voltage range and low input leakage on bus pins make THVD1500 an excellent choice for multi-point applications over long cable runs.

Figure 9 THVD1500 Functional Block

Diagram

Figure 9 THVD1500 Functional Block

Diagram