SSZT501 April 2019 IWR6843

This post was co-authored with Lali Jayatilleke

In my last blog post, I discussed how TI’s millimeter-wave (mmWave) sensors provide intelligence at the edge for robotic arms in factories. Now, I’d like to discuss how mmWave technology provides intelligence at the edge for autonomous robots, enabling the sensors to make real-time decisions to slow or stop robots and ensuring their continual performance in industrial robotics applications.

TI mmWave sensors can be used in systems designed to help industrial robots avoid collisions, addressing a key concern associated with using robots that interact with humans and with other objects. If additional machine learning processing is necessary at the edge, mmWave sensors work seamlessly with an industrial-grade processor like a Sitara™ processor to provide additional intelligence.

| Simplify mmWave sensing in your robotics application | |

|

Read the white paper |

Much like how automotive advanced driver assistance systems use mmWave for surround-view monitoring and obstacle detection, mmWave sensors help solve similar challenges for autonomous guided vehicles such as logistic robots, delivery vehicles, forklifts and palette jacks, as shown in Figure 1.

Figure 1 Various Autonomous Guided

Vehicles

Figure 1 Various Autonomous Guided

Vehicles3D Point Cloud Detection

An mmWave sensor with a three-transmitter and four-receiver antenna configuration enables 3D object detection up to 30 m, with angular information in both the azimuth and elevation planes, in order to detect objects from a great height. This is useful for vehicles such as forklifts, where the sensors are positioned higher off the ground. A single sensor is capable of detecting objects across a 120-degree field of view, minimizing the number of sensors needed for a surround monitoring system.

High Resolution for Accurate Detection

Since mmWave sensors operate with a wide 4-GHz bandwidth, they can identify separate objects that are as close together as 4 cm, and operate in areas that may be obscured by darkness, dust or physical barriers. This high-resolution capability is necessary in order for the sensor to accurately count and identify objects or people and trigger the appropriate action in real time, such as stopping a robot before a collision.

In addition to real-time object sensing and avoidance, mmWave sensors provide additional functionality that enables smarter industrial robots.

Ground Speed and Edge Detection

TI mmWave technology provides sub-millimeter accuracy and a high degree of resolution for precise ground-speed sensing via Doppler shift, enabling sensor systems to calculate the ground speed of a vehicle and detect ground edges, such as loading docks where wheels can slip, to avoid unrecoverable situations.

Transparent Object Detection

TI mmWave sensors can detect transparent objects such as glass and plastic as well as dark objects, which might be challenging for some light-based technologies to sense. Improving detection accuracy helps avoid potential mishaps such as collisions with glass barriers or objects.

SIL-2 Compliance

TI’s 60-GHz mmWave sensors help systems to meet the IEC Safety Integrity Level (SIL)-2 standards for incident management in close human-machine interaction. In designing a SIL-2 certified system, engineers could use TI mmWave sensors to provide functionality that might otherwise require system implementation of an additional safety processor system or redundant sensor system to obtain certification.

TI mmWave Sensors in Autonomous Robots

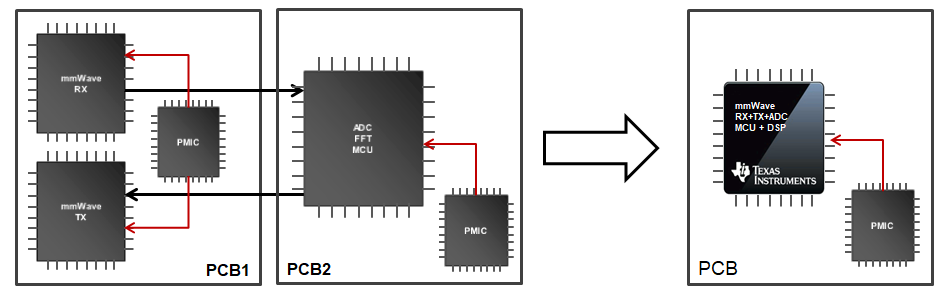

TI’s highly integrated mmWave radar sensors have advanced clustering and tracking algorithms as a part of the digital signal processor in order to deliver intelligent autonomy at the edge. Figure 2 shows a TI mmWave chip with integrated processing.

Figure 2 Comparison of a Typical Front End Sensor Solution and an Integrated TI mmWave Sensor, Which Enables Intelligence at the Edge.

Figure 2 Comparison of a Typical Front End Sensor Solution and an Integrated TI mmWave Sensor, Which Enables Intelligence at the Edge.Because TI mmWave sensors are not affected by environmental (rain, dust, smoke) and lighting conditions and can sense through materials such as plastic, they don’t need external lenses, apertures or sensor surfaces in order to effectively detect objects in a robot’s path.

More Intelligence at the Edge

Deep learning, a subset of machine learning, is gaining popularity in the industrial space. TI offers hardware and software support to help designers bring deep learning inference to the edge for a variety of applications, including robotics.

For applications where smart sensing isn’t enough, the Sitara AM57x processor family, equipped with high-performance Arm® Cortex®-A15 cores running at up to 1.5 GHz and dual-core C66x processors, is capable of running deep learning inference as well as traditional machine vision algorithms to solve machine learning needs for applications such as predictive maintenance and remaining useful life, or to make decisions based on a sensor input beyond existing capabilities. Sitara AM57x processors provide dedicated hardware for industrial communications (EtherCAT, Profinet, time-sensitive networking, Profibus, Ethernet/Internet Protocol) and can serve as the central processing unit of a robot controller.

To conclude, the integrated mmWave sensing solution for robust object detection, along with the Sitara processor for enhanced machine learning, provides an intelligent solution for area scanners around robotic arms or collision avoidance for autonomous robotics. To kick start development, refer to our resources.

Additional Resources

- To see how TI mmWave sensors work with Sitara processors to enable smart robotics, watch the video, “Robotics Using mmWave.”

- Start developing with our latest reference design, “Autonomous robotics reference design with Sitara processors and mmWave sensors using ROS.”

- Read the white paper, “Choosing 60-GHz mmWave sensors over 24 GHz to enable smarter industrial applications.”

- Read the application note, “mmWave Radar Sensors: Object Versus Range.”

- Learn more in our white paper, “How sensor data is powering AI in robotics.”

- Read about deep learning at the edge in this blog post and white paper.