SSZTBI0 march 2016 LM5140-Q1

Many industrial and automotive applications use the synchronous buck converter power-supply topology; these applications also require low conducted and radiated emissions to ensure that the power supply does not interfere with other equipment sharing the same bus (input voltage [VIN]). For example, in an automotive infotainment system, electromagnetic interference (EMI) could result in unwanted noise in the car stereo.

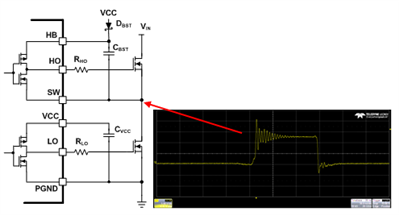

Figure 1 shows a synchronous buck-converter schematic, along with its switch-node waveform. The ringing on the peak of the switch-node waveform is a function of both the high-side MOSFET’s switching speed and the high-side and low-side MOSFETs and printed circuit boards (PCB) stray inductance and capacitance. The ringing on the switch-node waveform is unwanted because it can increase the voltage stress on the low-side MOSFET and generate EMI.

Figure 1 Synchronous Buck

Converter

Figure 1 Synchronous Buck

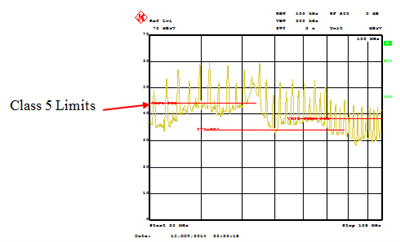

ConverterTo determine the relationship between the switch-node ringing of the buck converter in Figure 1 and the EMI that it generates, I ran conducted emissions testing in accordance with Comité International Spécial des Perturbations Radioélectriques (CISPR) 25 Class 5. Figure 2 shows the results. The measured data shows that the buck converter’s conducted emissions exceed Class 5 limits by 15dBµV in the 30MHz-108MHz frequency range.

Figure 2 CISPR 25 Class 5,

30MHz-108MHz, Buck Converter vIN = 12V, vOUT = 3.3V,

IOUT = 5A

Figure 2 CISPR 25 Class 5,

30MHz-108MHz, Buck Converter vIN = 12V, vOUT = 3.3V,

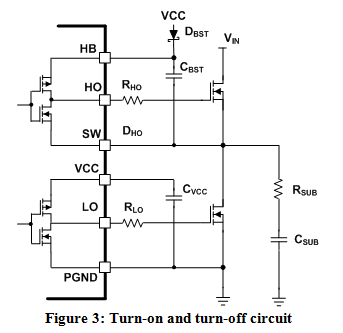

IOUT = 5AThe first step to lower the EMI is to reduce the switch-node ringing. There are several methods: the first is to slow down the MOSFET’s turn-on and turn-off time, which controls the rise and fall time of the switch node. You can do this by adding resistors in series (RHO and RLO) with the MOSFET’s gate leads; see Figure 3. A second method step is to add a snubber (RSUB and CSUB) from the switch node to ground. The snubber circuit dampens the parasitic inductances and capacitances during switching transitions.

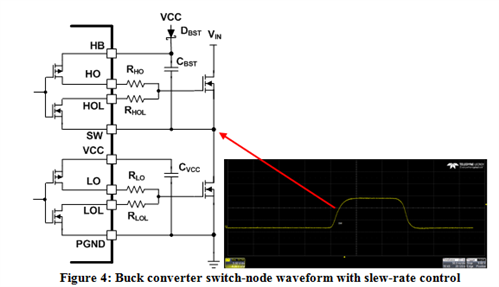

An alternative to using the methods describe above to reduce switch-node ringing is to use the LM5140-Q1 automotive-qualified synchronous buck controller. One of the key features of the LM5140-Q1 is slew-rate control. By pinning out the driver’s source and sink leads, you can independently control the turn-on and turn-off time of both the high- and low-side MOSFETs.

During the period when the low-side bottom MOSFET is turning off and the high-side top MOSFET is turning on, the switch-node voltage rises from ground to VIN. If the high-side top MOSFET turn-on time is too fast, there is a high overshoot in the switch-node voltage during this transition. Increasing the RHO resistor decreases the drive current to the high-side MOSFET, slowing down this MOSFET’s turn-on time and helping reduce switch-node ringing. Note that slowing down the high-side MOSFET’s turn-off time will increase the switching losses. You will need to make a trade-off when selecting RHO between low EMI and the high-side MOSFET’s switching losses.

The losses in the low-side MOSFET include RDS(ON) losses, dead-time losses and losses in the MOSFET’s internal body diode. During the dead time (when the high- and low-side MOSFETs are turned off) the low-side MOSFET’s internal body diode conducts the inductor current. The MOSFET’s internal body diodes typically have a high forward-voltage drop, so there can be a significant reduction in efficiency. Reducing the time that the low-side MOSFET’s internal body diode conducts current improves efficiency.

Using slew-rate control, a resistor (ROL) can be inserted between the LM5140-Q1 driver output (LO pin) and the low-side MOSFETs gate to increase the time that it takes for the low-side MOSFET to turn-off. Slowing down the turn-off time decreases the dead time between the low- and high-side MOSFETs’ conduction, increasing buck-converter efficiency. When reducing the dead time for a synchronous buck, make sure that the high- and low-side MOSFETs never conduct at the same time.

I modified the power supply shown in Figure 1 using the LM5140-Q1 controller (see Figure 4). Using slew-rate control optimizes the switch-node rise and fall time, eliminating switch-node ringing.

The next step is to run the CISPR 25 Class 5 conducted emissions. I chose these slew-rate control-resistor values: RHO = 10Ω, RHOL = 0Ω, RLO = 10Ω and RLOL = 10Ω. The resistors I selected for this application are a good startup point for any application where the output power is under 50W.

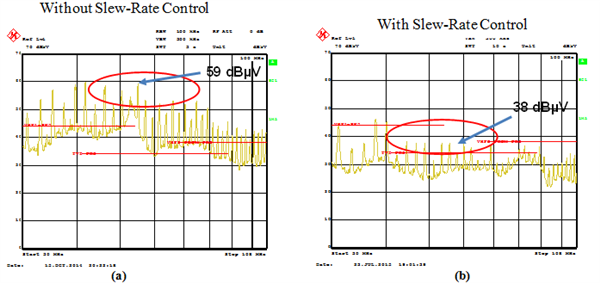

Figure 3 shows the results and summary of the conducted emissions testing.

Figure 3 Slew-rate Control Comparison:

CISPR 25 Class 5, vIN = 12V, vOUT = 3.3V, IOUT

= 5A, without Slew-rate Control (a) and with Slew-rate Control (b)

Figure 3 Slew-rate Control Comparison:

CISPR 25 Class 5, vIN = 12V, vOUT = 3.3V, IOUT

= 5A, without Slew-rate Control (a) and with Slew-rate Control (b)The buck converter using the LM5140-Q1 with slew-rate control reduced conducted emissions by 21dBµV. It also provided better control of the switch-node rise and fall and eliminated the need for a snubber circuit, which adds circuit complexity and cost.

By picking the correct values of slew-rate control resistors, not only can you reduce EMI; you can also improve system efficiency.

See a live demonstration of the LM5140-Q1 buck converter in TI’s booth (No. 1617) at the Applied Power Electronics Conference (APEC), March 21-23 in Long Beach, California. Follow TI at www.ti.com/apec2016.

Additional Resources

- Watch the video “Engineer it: How to use slew rate control for EMI reduction.”

- See the LM5140-Q1 data sheet.

- Open the “LM5140-Q1 Evaluation Module User’s Guide.”