SSZTD49A September 2024 – October 2024 BQ25756 , BQ25798 , TPS25751 , TPS26750

With applications in personal electronics, automotive, industrial and enterprise systems, USB Type-C® (USB-C®) is an industry-standard connector that enables the transmission of both data and power on a single interface. USB Power Delivery (PD) is a standard using the USB-C connector that increases the capabilities and features of a USB-C interface. Until recently, the USB PD 3.0 specification allowed for up to 100W (20V, 5A) of power, now called Standard Power Range (SPR), to flow in both directions. The latest USB PD 3.1 specification increases the power range to 240W (48V, 5A), now called Extended Power Range (EPR), through a USB-C cable.

Table 1 shows how EPR compares to SPR.

| Power range | Available current and voltages | Power delivery profile range | Notes |

|---|---|---|---|

| SPR | 3A: 5V, 9V, 15V, 20V 5A 1: 20V |

15W-60W >60W-100W |

|

| EPR | 5A 2: 28V, 36V, 48V | >100W-240W | Requires entry into EPR mode |

- Requires 5A cable.

- Requires EPR cable.

EPR allows support for up to 240W of power (28V, 36V and 48V at 5A). EPR mode has the same requirement for sinks to evaluate and respond to new source capabilities messages as in a typical USB PD contract negotiation. After entering EPR mode, a port starts to negotiate a power delivery object (PDO) as high as 240W (48V, 5A). The 48V limit represents a practical limit when considering design safety margins.

On top of the fixed voltage-level extension in EPR mode, the supply must also follow the specifications for an adjustable voltage supply (AVS). Within EPR mode, AVS enables the sink to fine-tune the voltage between 15V and 48V in steps of 100mV for improved performance and thermal efficiency. AVS also allows flexibility for the sink to receive voltages from any charger, which enables you to avoid custom adapters and create a consistent user experience within your electronic ecosystem.

Figure 1 shows the programmable power supply (PPS) and AVS ranges with respect to SPR and EPR power levels. While PPS and AVS both have programmable step sizes, they are not the same and are intended for different uses. AVS acts as a constant voltage supply and provides a steady DC voltage to the system in order to improve efficiency. PPS has a smaller step-size window (20mV) and can directly charge a battery, bypassing the battery charger in a connected device. The main difference between AVS and PPS is that with PPS, the negotiated voltage will constantly change over time. As the battery charges, the required PPS charge voltage will increase. AVS is intended to be a constant supply that provides a system input voltage to a voltage level closer to what the system requires as a whole.

Figure 1 USB PD 3.2 voltages required for the

source

Figure 1 USB PD 3.2 voltages required for the

sourceBattery-powered products and next-generation solutions

Portable battery-powered products such as Bluetooth® speakers and power tools will benefit from the adoption of USB-C. Implementing USB-C for these types of products enables them to both charge from the USB-C port as well as supply power to a connected device using the same port. Products using a single or multicell battery charger can now be paired with a USB-C or USB PD controller, which enables the applications to source and sink power from the USB-C port.

Figure 2 illustrates a typical architecture for devices transitioning to USB-C and USB PD.

Figure 2 USB-C battery-powered products block

diagram

Figure 2 USB-C battery-powered products block

diagramTo help simplify the design of the USB PD port for battery-powered products, TI's USB PD controllers add I2C host support to directly control the battery charger. This integrated I2C host control enables a two-chip solution without the need for an external microcontroller (MCU). The USB PD controller will automatically update the charging parameters of the battery charger through I2C based on the power negotiation over the USB PD port. Additionally, you don’t need to develop firmware to add a USB PD port to battery-powered products. The TPS25751 and TPS26750 are two USB PD controllers used for USB-C-plus-battery charger pairings.

The TPS25751 is an SPR PD controller, while the TPS26750 is an EPR PD controller capable of negotiating the full 240W EPR. Table 2 shows recommended USB PD controller and battery charger pairings. Reference designs for these pairings allow you to copy and paste the design into your applications.

| Maximum supported power levels | Supported cells in series count (S) | Recommended USB PD controller | Recommended battery charger | Reference design |

|---|---|---|---|---|

| 100W sink 45W source |

1-4 | TPS25751 | BQ25798 | Integrated USB Type-C® Power Delivery (PD) and Charging Reference Design for 2-4 Cell Batteries |

| 100W sink 100W source |

1-5 | TPS25751 | BQ25731 | Integrated USB Type-C® PD Bidirectional Charging Reference Design for One- to Five-Cell Batteries |

| 100W sink 100W source |

1-16 | TPS25751 | BQ25756 | 100W Integrated USB Type-C® PD Bidirectional Charger Reference Design |

| 240W sink 240W source |

1-16 | TPS26750 | BQ25756 | 240W USB Type-C PD3.1 EPR Battery Charger Reference Design |

Reference designs

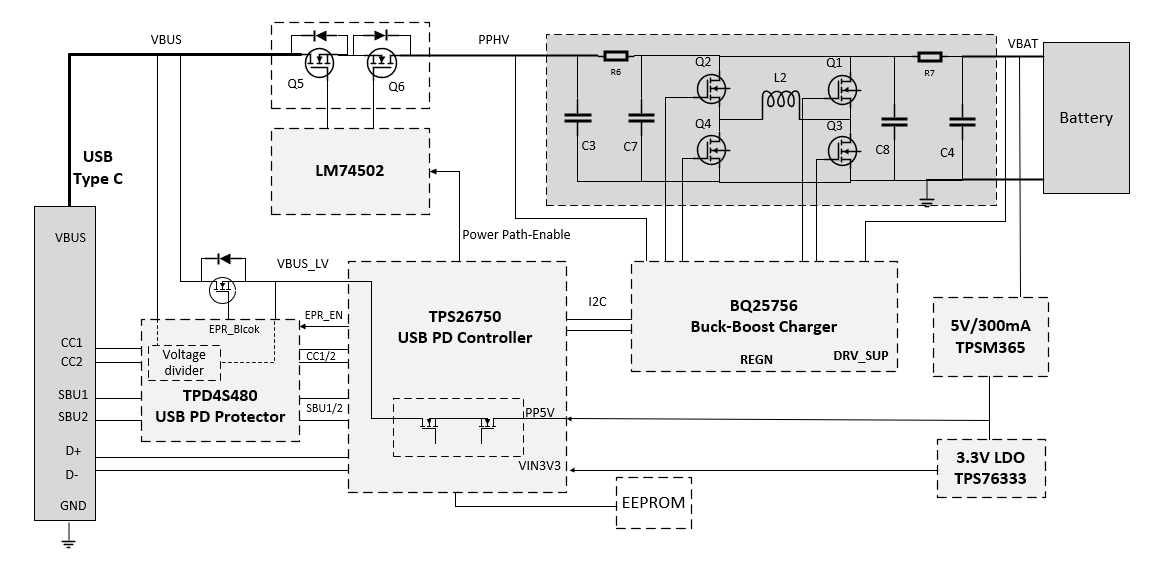

To support the full 240W extended power range, the 240W USB Type-C PD3.1 EPR Battery Charger Reference Design pairs the TPS26750 with our BQ25756 bidirectional buck-boost charge controller. As shown in Figure 3, this reference design pairs these two devices onto a single printed circuit board, enabling a bidirectional 240W solution without the need for an external MCU or custom firmware.

Figure 3 EPR battery charger reference design

block diagram

Figure 3 EPR battery charger reference design

block diagramThe battery charger reference design is an integrated USB PD and charging reference design for seven- to 14-cell batteries for products such as power tools, vacuum cleaners, portable power stations and e-bikes. The TPS26750 works with the BQ25756 through simple I2C communication, requiring no firmware development. Programming the TPS26750 is easy through the use of the application customization tool for TI USB PD controllers.

The battery charger reference design can support charging batteries with a maximum of 240W through a USB PD 3.1 compliance input source and provide a maximum 48V, 5A output in on-the-go mode. The BQ25756 implements a four-switch buck-boost charger, transitioning between buck, buck-boost and boost modes. The high integration and simple design will lower bill-of-materials costs, provide a smaller size, and reduce time to market.

Conclusion

With the newly increased maximum power range, USB-C is establishing itself as the universal connector of the future. While USB-C may be viewed as a new and challenging technology, TI solutions offer integration from both a software and hardware perspective in order to simplify your design process. Our USB PD controller and battery charger pairing, coupled with our reference designs, enable a lower solution size and reduced time to market.

Additional resources

- Watch our latest demo, USB Type-C Power Delivery 3.1 Extended Power Range + Battery charger Application Demo

- Watch our video, USB Type-C: The Future of Connectivity

- Learn more about our USB Type-C technologies

- Discover our USB Type-C and USB Power Delivery ICs

- Watch our latest liquid detection demo video

- Read our latest white paper, A Primer on USB Type-C and USB Power Delivery Applications and Requirements

Trademarks

All trademarks are the property of their respective owners.