-

BAW Oscillator Solutions for Motor Drivers

BAW Oscillator Solutions for Motor Drivers

BAW Resonator Technology

BAW is a micro-resonator technology that enables the integration of high-precision and ultra-low jitter clocks directly into packages that contain other circuits. In the LMK6C and CDC6CLVCMOS oscillators, BAW is integrated with a co-located precision temperature sensor, a ultra-low jitter, low power output divider, and a small power-reset-clock management system consisting of several low noise LDOs.

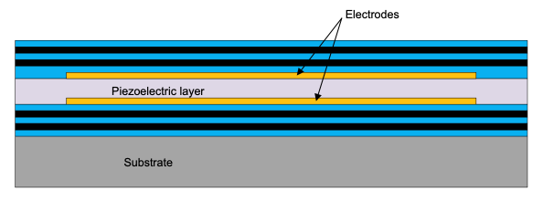

Figure 1 shows the structure of the BAW resonator technology. The structure includes a thin layer of piezoelectric film sandwiched between metal films and other layers that confine the mechanical energy. The BAW utilizes this piezoelectric transduction to generate a vibration.

Figure 1 Basic Structure of a Bulk

Acoustic Wave (BAW) Resonator

Figure 1 Basic Structure of a Bulk

Acoustic Wave (BAW) ResonatorBAW Oscillator in Motor Drive Systems

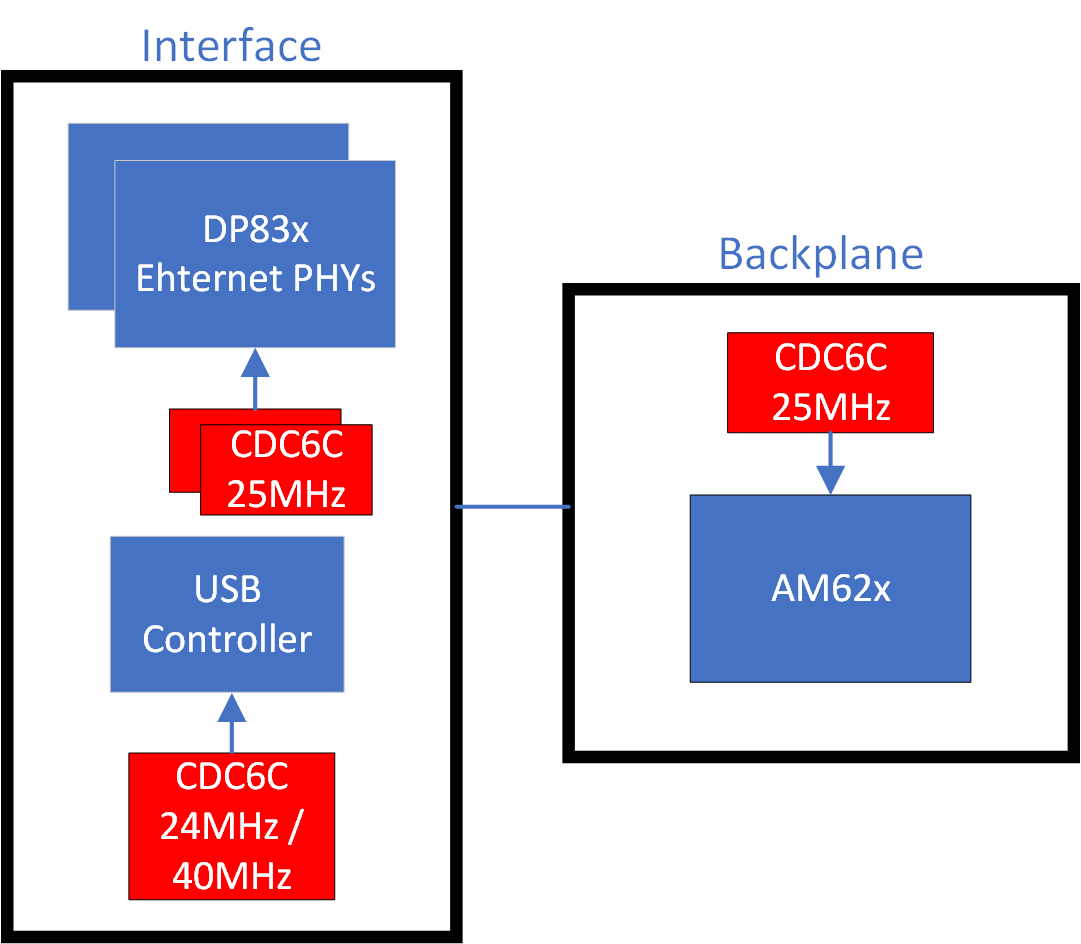

Motor drive systems are used in many industrial and manufacturing applications. These systems require precise control of position, torque, and speed for robust and reliable performance. Many applications such as AC inverter and VF drives, single and multi-axis servo drives, and stepper drives rely on EtherCAT® to transmit data to the host processor, which requires a reliable clocking architecture to achieve the best performance. Figure 2 shows a common clocking architecture for standard EtherCAT applications.

Figure 2 Typical Block Diagram of BAW

Oscillator used in Motor Drive EtherCAT Applications

Figure 2 Typical Block Diagram of BAW

Oscillator used in Motor Drive EtherCAT ApplicationsBenefits of the BAW Oscillator

TI's BAW oscillators have many benefits including the following:

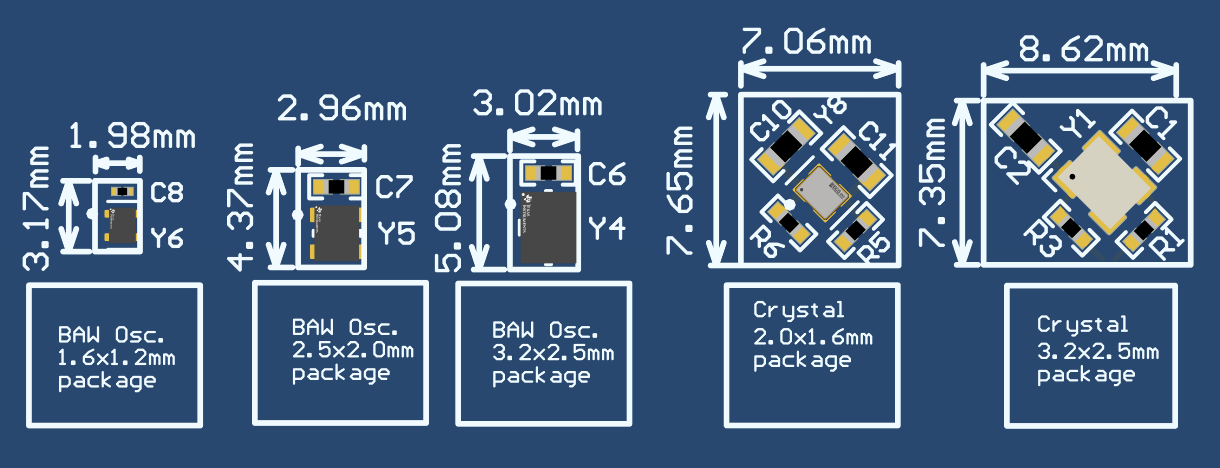

- BAW oscillators are available in standard 4-pin package sizes, including the industry's smallest 1.6mm x 1.2mm. Figure 3 showcases BAW Oscillator layouts on the left in comparison to typical crystal layouts for several package sizes. Crystals require up to four external components to tune the resonant frequency and maintain active oscillation. Active oscillators such as the CDC6C or LMK6C only require a single capacitor for power supply filtering, which simplifies the BOM and significantly reduces the layout area required. Additionally, parasitic capacitance from PCB traces will not affect the frequency accuracy of an active oscillator which allows it to be placed much farther away from the receiver compared to crystal.

Figure 3 PCB Footprint Comparison of

BAW Oscillator and Crystal

Figure 3 PCB Footprint Comparison of

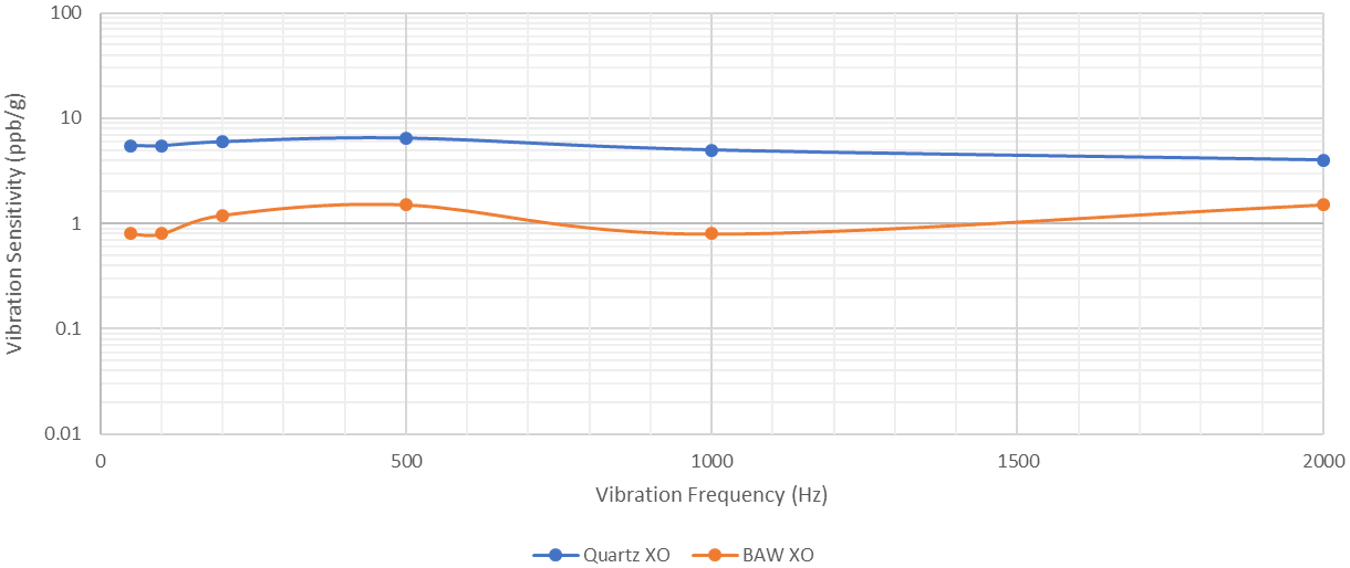

BAW Oscillator and Crystal- BAW technology enables high resiliency to harsh environmental conditions, such as mechanical shock and vibration and achieves 100× better MTBF compared to quartz based designs. As shown in Figure 4, BAW oscillators experience only 1 ppb/g vibration sensitivity, which is 10× better than quartz-based designs.

Figure 4 BAW Oscillator Vibration

Sensitivity

Figure 4 BAW Oscillator Vibration

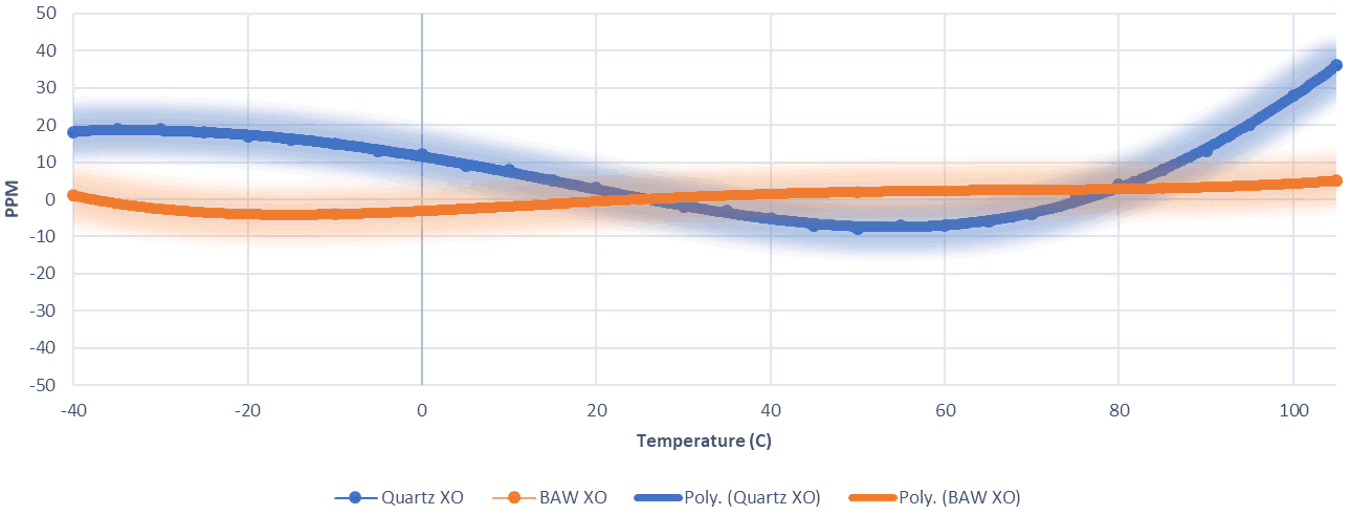

Sensitivity- BAW oscillators maintain a temperature stability of ±10 ppm over temperature from -40 to +105°C.

Figure 5 Temperature Stability

Comparison of BAW Oscillator and Quartz

Figure 5 Temperature Stability

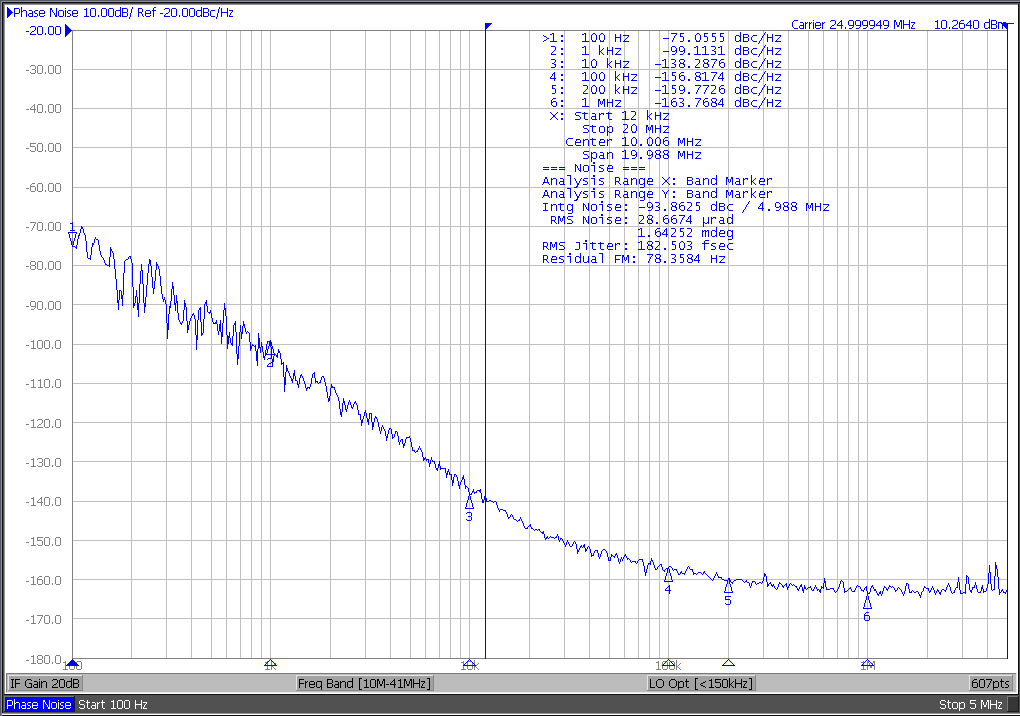

Comparison of BAW Oscillator and Quartz- LMK6C oscillators support a typical RMS jitter of 200fs, resulting in optimized bit-error-rate (BER) performance of the Ethernet PHY.

Figure 6 LMK6C BAW Oscillator 25MHz

Phase Noise Performance

Figure 6 LMK6C BAW Oscillator 25MHz

Phase Noise Performance- BAW oscillators include an integrated LDO which provides high-power supply noise immunity.

Figure 7 LMK6C/CDC6C BAW Oscillator

Simplified Block Diagram with Integrated LDO

Figure 7 LMK6C/CDC6C BAW Oscillator

Simplified Block Diagram with Integrated LDOIMPORTANT NOTICE AND DISCLAIMER

TI PROVIDES TECHNICAL AND RELIABILITY DATA (INCLUDING DATASHEETS), DESIGN RESOURCES (INCLUDING REFERENCE DESIGNS), APPLICATION OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND OTHER RESOURCES “AS IS” AND WITH ALL FAULTS, AND DISCLAIMS ALL WARRANTIES, EXPRESS AND IMPLIED, INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT OF THIRD PARTY INTELLECTUAL PROPERTY RIGHTS.

These resources are intended for skilled developers designing with TI products. You are solely responsible for (1) selecting the appropriate TI products for your application, (2) designing, validating and testing your application, and (3) ensuring your application meets applicable standards, and any other safety, security, or other requirements. These resources are subject to change without notice. TI grants you permission to use these resources only for development of an application that uses the TI products described in the resource. Other reproduction and display of these resources is prohibited. No license is granted to any other TI intellectual property right or to any third party intellectual property right. TI disclaims responsibility for, and you will fully indemnify TI and its representatives against, any claims, damages, costs, losses, and liabilities arising out of your use of these resources.

TI’s products are provided subject to TI’s Terms of Sale (www.ti.com/legal/termsofsale.html) or other applicable terms available either on ti.com or provided in conjunction with such TI products. TI’s provision of these resources does not expand or otherwise alter TI’s applicable warranties or warranty disclaimers for TI products.

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2024, Texas Instruments Incorporated