-

5 Questions to Ask When Designing with Rechargeable Batteries for Personal Care Products

- 1

-

2

- 3

- Do you want to charge the device from USB or all possible power sources?

- How much do you need – or want – to simplify your design?

- How important is fast-charging capability and an extended battery life?

- 4. How long does the shelf-life of the product need to be?

- 5. What protection features are required?

- Additional resources

- IMPORTANT NOTICE

5 Questions to Ask When Designing with Rechargeable Batteries for Personal Care Products

Alan Lee

Beauty and personal care products have traditionally been designed with a traditional AC power supply. Therefore, every time consumers use such products, they need to be close to the wall, and any movement and power is restrained by the length of the electrical cord. As modern electronics have evolved, consumers now expect to be able to use personal care products such as a shavers, epilators, muscle massagers, electric toothbrushes and face-cleansing products without being tethered to a wall socket.

To meet consumer demands, today’s personal care products, like those shown in Figure 1, include a primary battery, a small DC motor and a rotating accessory. It remains a challenge to ensure a battery life of more than one hour for these applications, however, particularly when they rely on AA or AAA batteries. To help extend battery life and flexibility for consumers, lithium-ion (Li-ion) batteries can help make personal care products more portable.

Figure 1 Examples of Li-ion

battery-powered personal care products

Figure 1 Examples of Li-ion

battery-powered personal care productsLi-ion batteries offer high power density in addition to being lightweight and small. It’s common for design engineers to either choose a single- or two-cell Li-ion battery configuration for the design of personal care products, but there are trade-offs between the two options.

Here are five questions to ask when choosing a charger integrated circuit (IC) for a Li-ion battery-charger design.

Do you want to charge the device from USB or all possible power sources?

You’ve likely had the experience where you simply cannot find the dedicated adapter you need to charge a particular product. Between your smartphone, smartwatch, notebook, shaver, camera and whatever else you’re traveling with, it seems that each device requires a different adapter to charge.

Li-ion batteries charger ICs can support charging through various adapters and a wide voltage range, from 4 V to 17 V. Keep in mind that charger ICs with anything lower than a 20-V input will require an external overvoltage protection IC to prevent electrical surges.

With new homes, airports and hotels now supporting embedded USB charging ports, universal charging from these adapters is an important design choice, and will aid in enhancing the convenience of using the product.

How much do you need – or want – to simplify your design?

Hardware and software implementation can be a cumbersome and costly task – R&D time is precious. Choosing a charger IC for easy layout on two-layer printed circuit board (PCBs) can help along with autonomous charging, precharge, constant current(CC) fast charge and constant-voltage(CV) charging to termination. A two-layer design also makes it easier to debug the hardware. If you choose a stand-alone IC, all charge voltage and current are preset by external resistors. This means you will not need to program your charger IC with software.

How important is fast-charging capability and an extended battery life?

Time is precious, and consumers have little patience to charge their devices longer than a few minutes before use. Ideally, full charging should be complete within an hour.

To enable quick charging for immediate use of the product, the charger IC needs to do high-current charging safely and accurately. In addition, customers should be able to recharge the battery more than 500 times and have the battery still deliver at the same load current as it did when it was new for many months or years, depending on how often it is used.

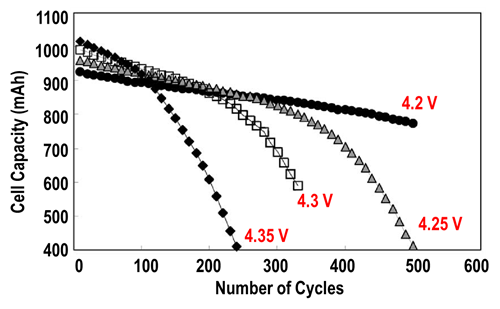

Li-ion battery chargers need to have highly accurate charge current and voltage control across different conditions (listed in the parametric data sheet) to avoid charging higher than the battery specification voltage in any condition. Every time the product is recharged, the battery terminal voltage is regulated precisely to a voltage such as 4.20 V (see Figure 2). Overcharging will decrease the number of recharge cycle with battery capacity loss.

Figure 2 Li-ion battery recharge cycles and cell capacity loss caused by a higher-than-specified termination voltage (Source: “Factors that affect cycle-life and possible degradation mechanisms of

a Li-ion cell based on LiCoO2”)

Figure 2 Li-ion battery recharge cycles and cell capacity loss caused by a higher-than-specified termination voltage (Source: “Factors that affect cycle-life and possible degradation mechanisms of

a Li-ion cell based on LiCoO2”)4. How long does the shelf-life of the product need to be?

When the product is made with the battery only charged to 50%, it will typically take about three to six months to reach the hands of the consumer. Products with the battery connected will start losing battery life while in transit. Low quiescent current (IQ) in the charger is essential to support instant use by the consumer before a recharge is required.

5. What protection features are required?

Chargers for Li-ion batteries typically have multiple control loops. Those are dedicated to protecting the charger IC and battery during charging, such as over voltage protection, over current protection , pin open/short detection to prevent battery overcharge, , battery temperature sensing control, charger IC thermal regulation and thermal shutdown, etc. Accurately monitoring battery temperature and setting a pin to open for quick protection in any unexpected cases is something to consider in the design.

To help design engineers address many of these challenges, TI’s BQ25306 family of battery chargers is designed for universal charging of 1 cell in series (1s) and 2 cell in series (2s) batteries with a 4-V to 17-V input voltage and 28 V of protection for possible surges. With an external resistor setup, the BQ25306 family charges the battery automatically, and its 3-mm-by-3-mm quad flat no-lead package is small enough to accommodate a two-layer PCB design, as shown in Figure 3.

Figure 3 BQ25306 family block diagram

Figure 3 BQ25306 family block diagramFor more information on how to incorporate the BQ25306 into your next design of a personal care product, engage with our engineering community through the TI E2E™ support forum or see the additional resources below.

Additional resources

- Review the BQ25306 evaluation module.

- Read the article, “When to use rechargeable batteries in small battery applications.”

IMPORTANT NOTICE AND DISCLAIMER

TI PROVIDES TECHNICAL AND RELIABILITY DATA (INCLUDING DATASHEETS), DESIGN RESOURCES (INCLUDING REFERENCE DESIGNS), APPLICATION OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND OTHER RESOURCES “AS IS” AND WITH ALL FAULTS, AND DISCLAIMS ALL WARRANTIES, EXPRESS AND IMPLIED, INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT OF THIRD PARTY INTELLECTUAL PROPERTY RIGHTS.

These resources are intended for skilled developers designing with TI products. You are solely responsible for (1) selecting the appropriate TI products for your application, (2) designing, validating and testing your application, and (3) ensuring your application meets applicable standards, and any other safety, security, or other requirements. These resources are subject to change without notice. TI grants you permission to use these resources only for development of an application that uses the TI products described in the resource. Other reproduction and display of these resources is prohibited. No license is granted to any other TI intellectual property right or to any third party intellectual property right. TI disclaims responsibility for, and you will fully indemnify TI and its representatives against, any claims, damages, costs, losses, and liabilities arising out of your use of these resources.

TI’s products are provided subject to TI’s Terms of Sale (www.ti.com/legal/termsofsale.html) or other applicable terms available either on ti.com or provided in conjunction with such TI products. TI’s provision of these resources does not expand or otherwise alter TI’s applicable warranties or warranty disclaimers for TI products.

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2023, Texas Instruments Incorporated