SBOA401A June 2020 – March 2022 TMCS1100 , TMCS1100-Q1 , TMCS1101 , TMCS1101-Q1 , TMCS1107 , TMCS1107-Q1 , TMCS1108 , TMCS1108-Q1

3 Increasing Performance of Key Power Systems

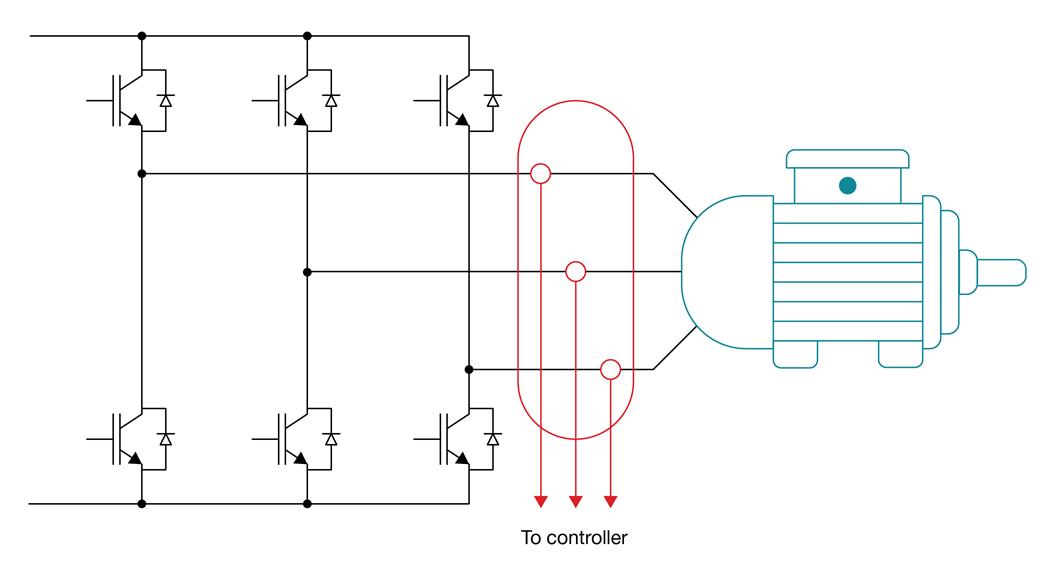

Electronic power systems rely on accurate feedback of operating characteristics to create tight control loops to optimize performance. As Figure 3-1 shows, many motor-control algorithms rely on sensing current through each phase of the motor to control torque and speed, and to accurately position the rotor. This current feedback must be isolated from the high-voltage bus, reject the voltage swings to which the current sensor is subjected, and maintain a high degree of matching between each phase. Low temperature drift reduces phase-to-phase errors of a load system, allowing operation with superior dynamic response and optimized torque or speed control, while reducing behavior such as torque ripple.

Figure 3-1 Three-Phase In-line Motor

Current Sensing

Figure 3-1 Three-Phase In-line Motor

Current SensingEnsuring stability of the current feedback over a wide range of operating, load, and environmental conditions is a significant design challenge. High temperature drift associated with existing magnetic solutions means that system designers have either limited control-loop performance or need to compensate with more complicated solutions or multipoint system-level calibration. In addition to being a costly solution, multipoint calibration cannot protect against degradation in performance over the lifetime of the system.

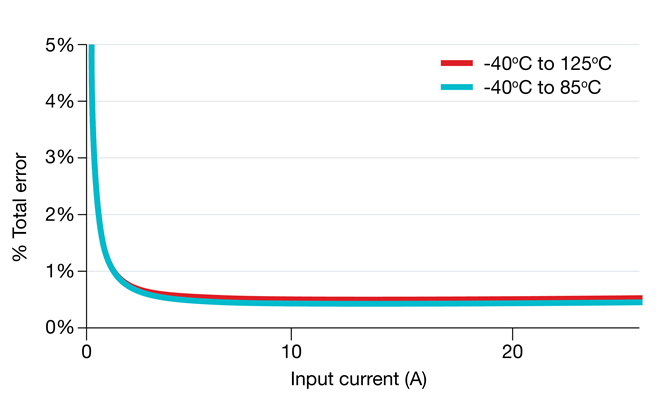

By providing a sensitivity temperature drift of < 0.3% and a low offset drift of < 10 mA across a temperature range from –40°C to 125°C, the TMCS1100 family enables performance across many environmental conditions. The combination of low offset and a 0.05% typical linearity enables high-precision current measurements across a wide dynamic load. Figure 3-2 illustrates how these performance specifications result in better than 0.5% full-scale accuracy– a level previously unachievable in a simple, easy-to-use form factor.

Figure 3-2 Accuracy Specifications and

Resulting Current Error of the TMCS1100

Figure 3-2 Accuracy Specifications and

Resulting Current Error of the TMCS1100The same device compensation techniques used to stabilize performance over temperature provide more than three times lower lifetime drift than most competitive solutions. Lifetime qualifications show a typical sensitivity drift less than 0.5%. This combination of high dynamic range, low thermal drift and lifetime stability enables measurement precision from a Hall-effect current sensor that was previously unattainable – improving system performance regardless of the time of year or environmental conditions, as well as over the lifetime of the system.