-

NTC Thermistor to TMP6 Linear Thermistor Replacement Guide

NTC Thermistor to TMP6 Linear Thermistor Replacement Guide

Trademarks

All trademarks are the property of their respective owners.

1 Introduction

Thermistors can be used in temperature sensing applications instead of digital temperature sensors due to their reduced cost, lower footprint, and faster response time. More information on the benefits of thermistors over digital temperature sensors can be found in Temperature Sensing using Thermistors.

1.1 NTC Thermistor Versus TMP6 Linear Thermistor Family

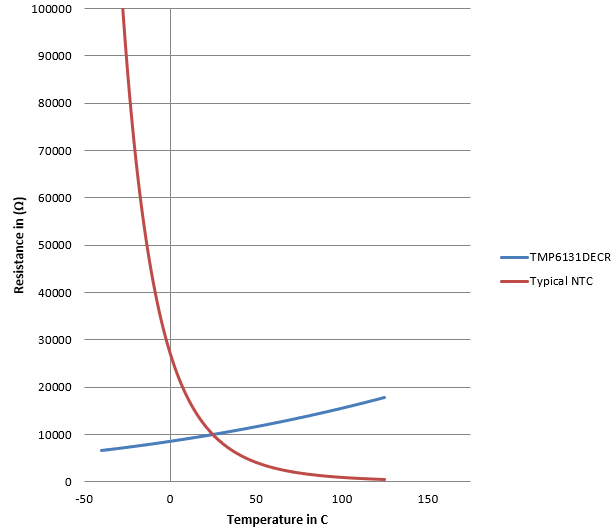

The two main thermistors in the market are the NTC and linear thermistors. NTC thermistors operate by changing the resistance as temperature increases or decreases. Linear thermistors change their effective resistance while a current is flowing through them, depending on the temperature. The largest difference between the two types is that NTC thermistor's resistance will decrease logarithmically while a linear thermistor's effective resistance will increase linearly as the temperature increases. The graph below shows the difference in resistance to temperature characteristics of a typical 10-kΩ NTC thermistor versus TI's TMP6 Linear Thermistor family, specifically the TMP6131 DEC package.

Figure 1-1 RT Curve of Typical NTC Thermistor vs. TMP6131DEC Thermistor.

Figure 1-1 RT Curve of Typical NTC Thermistor vs. TMP6131DEC Thermistor. 1.2 NTC/Linear Thermistor TCR

The temperature coefficient resistance (TCR) can be defined as the change in resistance as temperature changes for a device. Use Equation 1 to calculate the TCR measured in ppm/°C.

Due to the linearity of the TMP61 thermistor, the device has a consistent TCR across a wide operating temperature range. Unlike an NTC thermistor, which is a purely resistive device, the TMP61 thermistor's effective resistance is affected by the current across the device and the effective resistance changes when the temperature changes. The TMP61 thermistor has a 6400 ppm/°C TCR (25°C) with a 0.2% typical TCR tolerance across the entire temperature range. However, this value does vary slightly depending on how the TMP61 thermistor is biased.

The TMP6 thermistor has many advantages while the NTC thermistor, at first glance, has an advantage of change in resistance at room temperature. The TMP6 thermistor can achieve the same or better accuracy with simple enhancements that TI provides.