SCEU031B August 2024 – October 2024 TPLD801

PRODUCTION DATA

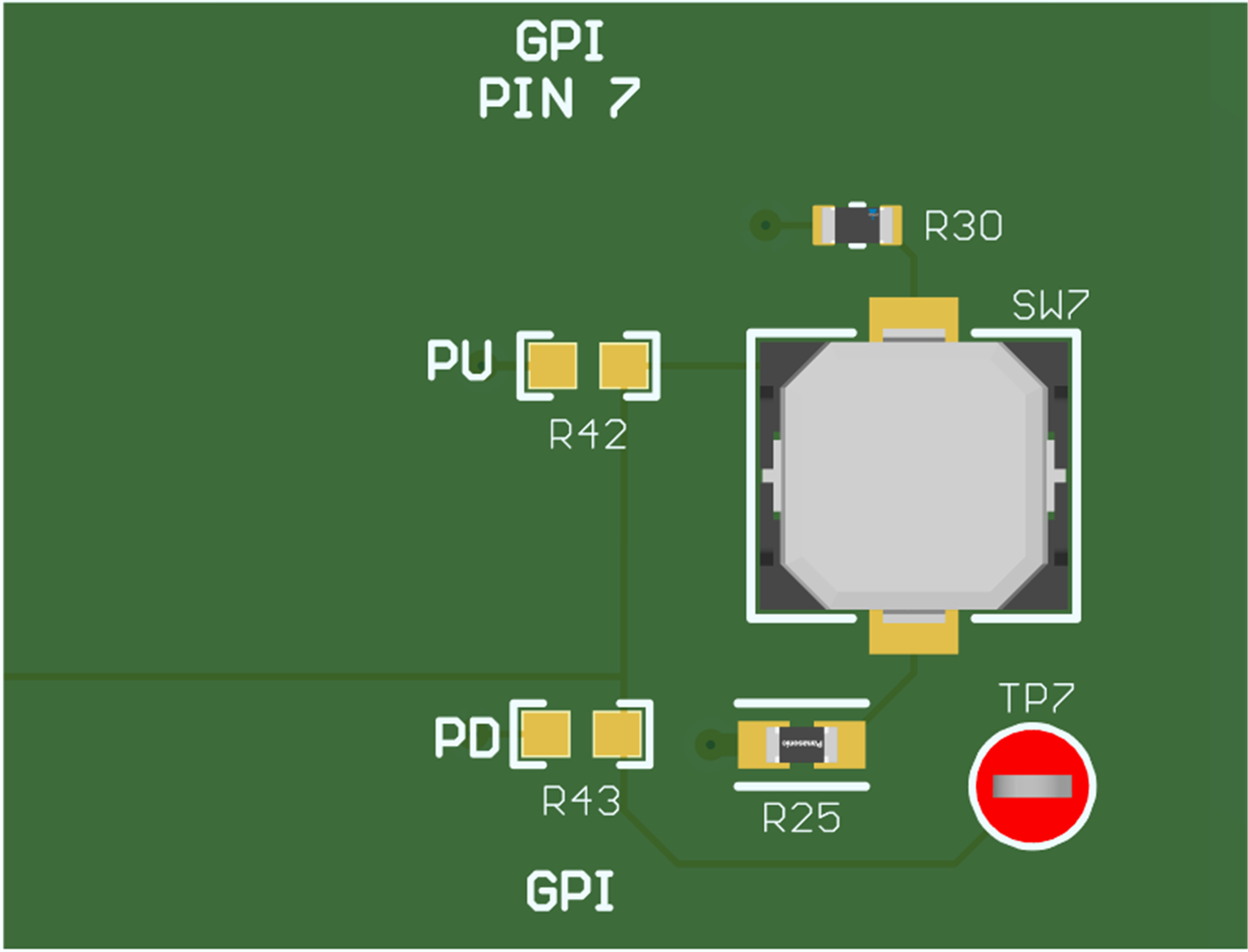

2.1.7 GPI Switch Testing Block

The GPI line is connected to a tactile switch. This switch has no debounce features. This is to protect the GPI signal during programming. The GPU switch block has soldering spots for optional pull-up and pull-down resistors. These are initially de-populated and are labeled PU and PD, respectively. Do not attempt to permanently program the device with either a pull-up or pull-down resistor installed on the GPI line.

Figure 2-4 GPI Switch Block

Figure 2-4 GPI Switch Block