SLAAE76B march 2023 – june 2023 MSPM0G1105 , MSPM0G1106 , MSPM0G1107 , MSPM0G1505 , MSPM0G1506 , MSPM0G1507 , MSPM0G3105 , MSPM0G3106 , MSPM0G3107 , MSPM0G3505 , MSPM0G3506 , MSPM0G3507

9.4 How to Select Board Layers and Recommended Stack-up

To reduce the reflections on high-speed signals, match the impedance between the source, sink and transmission lines. The impedance of a signal trace depends on its geometry and its position with respect to any reference planes.

The trace width and spacing between differential pairs for a specific impedance requirement is dependent on the chosen PCB stack-up. As there are limitations in the minimum trace width and spacing which depend on the type of PCB technology and cost requirements, a PCB stack-up needs to be chosen which allows all the required impedances to be realized.

The minimum configuration that can be used is 2 stack-up. A 4- or 6-layer boards are required for very dense PCBs that have multiple high-speed signals.

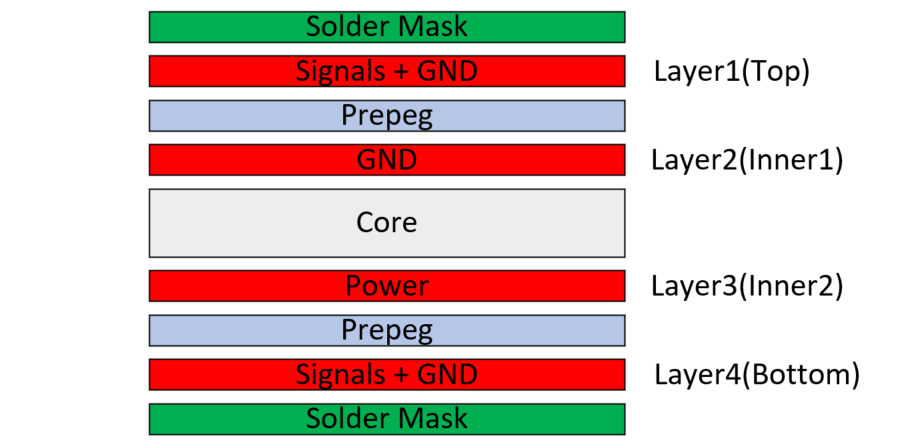

The following stack-ups Figure 9-5 are intended as 4-layer examples that can be used as a starting point for stack-up evaluation and selection. These stack-up configurations use a GND plane adjacent to the power plane to increase the capacitance and reduce the gap between GND and power plane. High-speed signals on the top layer have a solid GND reference plane that helps to reduce EMC emissions. Increasing the number of layers and having a GND reference for each PCB signal layer further improves the radiated EMC performance.

Figure 9-5 Four-Layer PCB Stack-up Example

Figure 9-5 Four-Layer PCB Stack-up ExampleIf the system is not very complicated, there is no high-speed signal or some sensitive analog signal, then the 2 stack-up structure is sufficient.