SLAAEK6 June 2024 ULC1001 , ULC1001-Q1

3.4.5.3 Housing Base

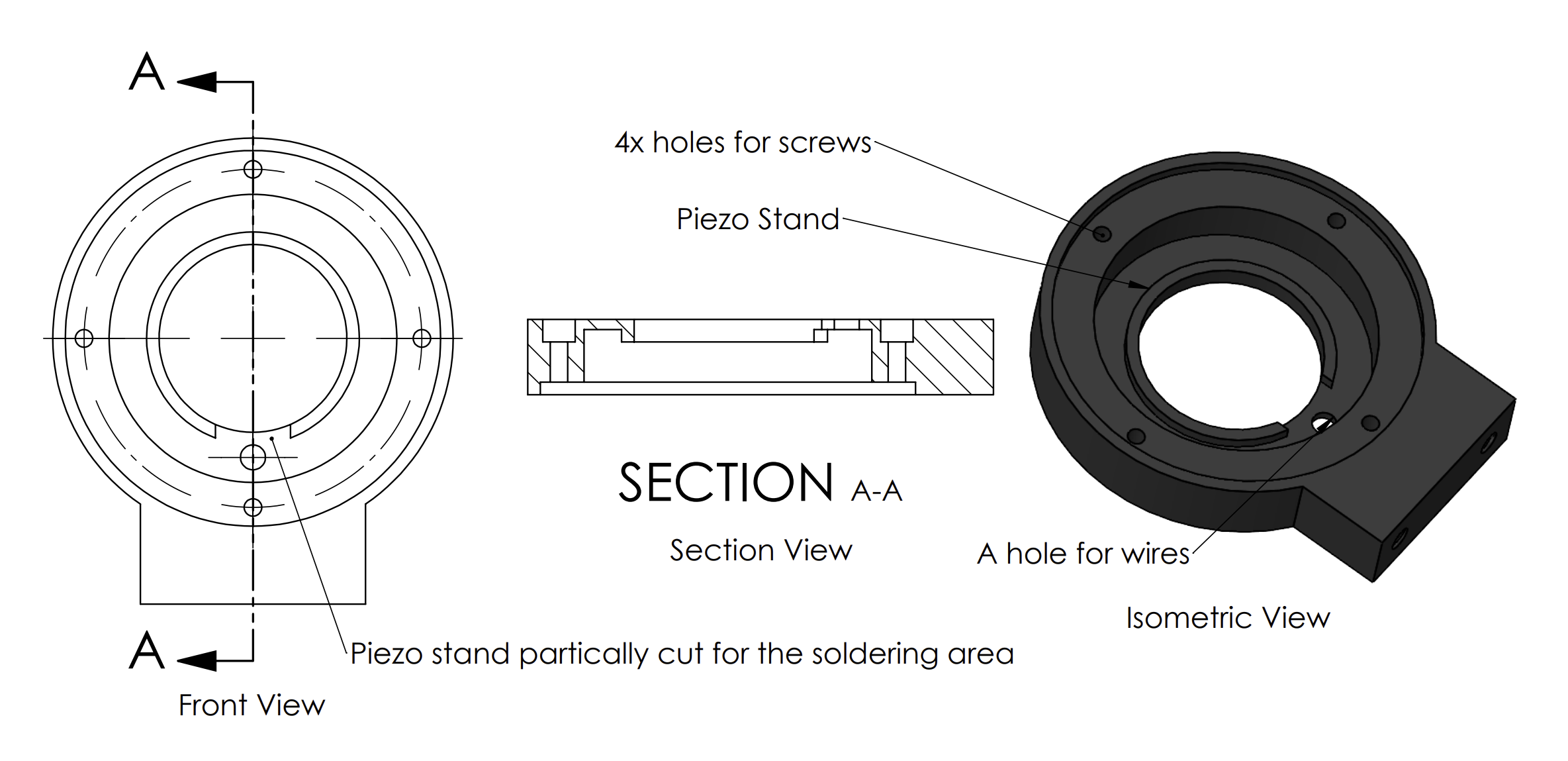

The purpose of the base is to hold the camera and the Lens Cover and to maintain their relative position. The base can keep the Lens Cover concentric with the camera lens and to prevent the Lens Cover from moving radially with respect to the housing. The base also has special accommodations for the wires going to the plates of the transducer. A small lip is designed to keep a small distance from the piezo to withstand in case the piezo faces an extreme large load. The 4x screws can connect the housing base, lens cover and the housing cap. Figure 3-12 show the front view, section view, and isometric view of the housing base.

Material: The cap material must be strong and durable for the application. TI used Delrin Acetal Homopolymer Black for prototyping.

Figure 3-12 Housing Base: Front View,

Section View, and Isometric View

Figure 3-12 Housing Base: Front View,

Section View, and Isometric View