SLAAEK6 June 2024 ULC1001 , ULC1001-Q1

4.1 Lens

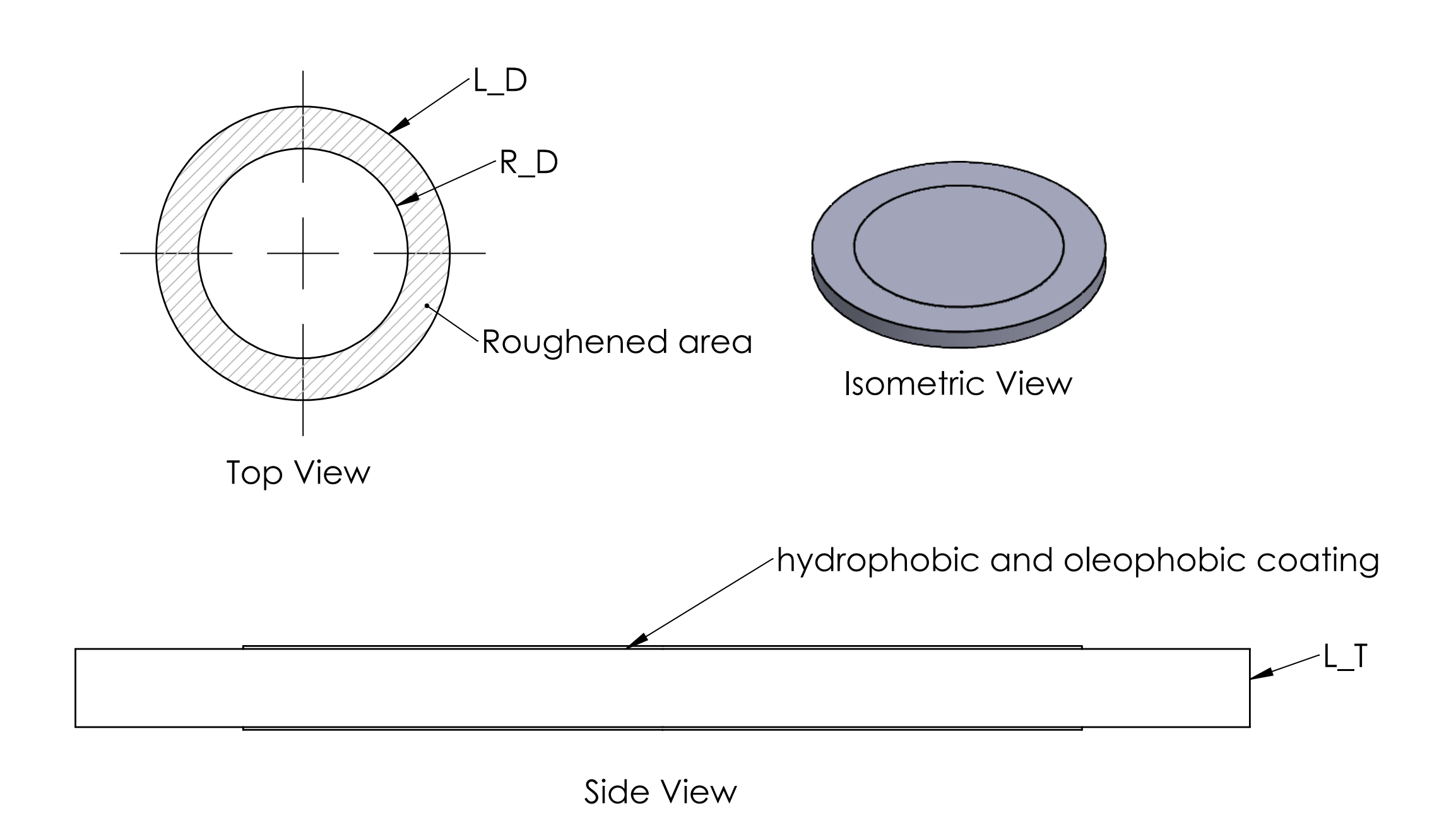

The lens is in the shape of a thin circular disk, as Figure 4-1 shows. There are a few important parameters for the lens: lens diameter (L_D), lens thickness (L_T), surface polishing, the etched outer diameters, and the etched ring surface roughness. The dimensions of the lens must be carefully designed to achieve the best cleaning performance.

Tips:

- The top and bottom surfaces of the lens must be polished to minimize surface cracks. The recommended polish level is 60/40.

- The bottom surface of the lens must have an etched area to increase the surface contacting area for gluing. The ring can be etched by several methods, including light sand blasting, chemical etching or laser etching, with an estimated surface roughness of 300 mesh (48um). The recommended method is light sandblasting.

- The etched ring diameter (R_D) must be slightly smaller than the transducer's inner diameter.

- The lens edges must also be polished. For additional crack protection, a protective bevel can be added to the lens edges to avoid chipping during fabrication and handling.

- Chemically strengthened lens is optional. Chemically strengthened lens typically have higher bending strength while other properties (for example, density, Young’s modulus and Poisson’s ratio) are held almost constant.

- Hydrophobic and oleophobic coating are recommended to reduce the surface tension of water.

Figure 4-1 Lens: Top View, Side View and Isometric View

Figure 4-1 Lens: Top View, Side View and Isometric View