SLAAEO3 September 2024 MSPM0L1227 , MSPM0L1227-Q1 , MSPM0L1228 , MSPM0L1228-Q1 , MSPM0L2227 , MSPM0L2228 , MSPM0L2228-Q1

4.1.1 Muxing Example

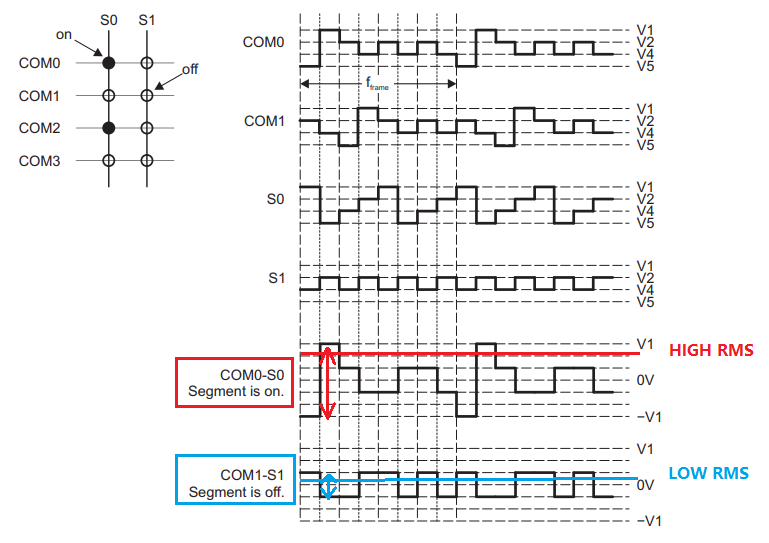

Figure 4-2 shows a 4-mux 1/3 bias waveform. Each segment is controlled by signals on 2 pins – a COMx pin and an Sx segment pin. The signals shown are the waveforms applied on the electrodes for the segment, so the potential difference between the Sx and COMx signal is what is applied to the liquid crystals in that area. This potential difference is what is shown as the voltage in the resultant waveforms in Figure 4-2 (COM0-S0 and COM1-S1).

In this example, the COM0-S0 waveform has a high RMS voltage so the segment is on even though the waveform has a net zero DC voltage. The COM1-S1 waveform has a low RMS voltage, so the segment is off. While the waveforms look complex, they are generated automatically by the MSPM0 LCD module – the user only specifies the basic settings of the LCD and indicates which segments is on or off.

Figure 4-2 4-Mux 1/3 Bias

Figure 4-2 4-Mux 1/3 Bias