SLOA312 December 2021 DRV8412 , DRV8424 , DRV8426 , DRV8428 , DRV8434 , DRV8436 , DRV8803 , DRV8804 , DRV8805 , DRV8806 , DRV8844 , DRV8847 , DRV8932 , DRV8935 , DRV8955

PRODUCTION DATA

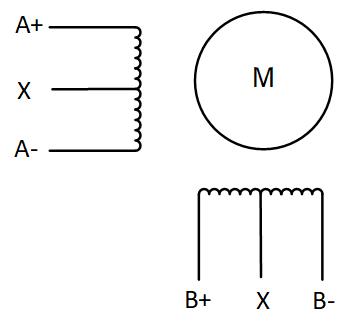

2.1 Unipolar Stepper Motors

Unipolar stepper motors have two windings per phase. The common wiring configuration for unipolar motors is four wires connected to the motor windings (A+, A-, B+ and B-) and a center tap on each phase. The center taps can be electrically isolated; or they can be shorted electrically. The center taps are generally connected to the motor voltage supply, VM.

Figure 2-1 Unipolar Stepper Motor

Figure 2-1 Unipolar Stepper MotorCurrent flows from VM supply to only one half of a winding at any given time. The center tap allows the magnetic field to be reversed without having to reverse the direction of current in a winding. The tradeoff is that because only half of each winding is used at a given time, unipolar steppers result in lower torque and efficiency.

However, as current flows only in a single direction, the driver electronics for unipolar stepper motors can be simpler compared to bipolar stepper motors. Only four low-side MOSFETs and circulating diodes are sufficient to drive a unipolar stepper motor.