SLVAFF1 January 2023 DRV8452 , DRV8462

PRODUCTION DATA

- Abstract

- Trademarks

- 1Power Efficiency of Stepper Motor Drivers

-

2Auto-Torque

- 2.1 Auto-Torque: Learning Principle

- 2.2 Current Control

- 2.3 PD Control Loop

- 2.4

Impact of Auto-Torque Tuning

Parameters

- 2.4.1 Impact of Learning Parameters on Load Transient Response

- 2.4.2 Impact of ATQ_UL, ATQ_LL Hysteresis

- 2.4.3 Impact of Load Profile on Power Saving

- 2.4.4 Adaptive ATQ_UL, ATQ_LL

- 2.4.5 PD Parameter Dependency Curves

- 2.4.6 ATQ_CNT at Different Motor Speeds

- 2.4.7 ATQ_CNT at Different Supply Voltages

- 2.4.8 Motor Temperature Estimation

- 2.5 Efficiency Improvement With Auto-Torque

- 3Case Studies

- 4Summary

- 5References

3.2.2 Textile Motor With Auto-Torque

In this application, the stepper motor was subjected to load torque transients between 50 mNm and 1.5 Nm at a fast rate of 1.5 Nm/15ms. The on time for the peak load was roughly 1 s, and the duration between peak load events was 4 s, corresponding to a 20% duty cycle for the peak load.

Figure 3-6 shows the snapshot of the learning routine for this motor.

The auto torque learning routine was run at no load with the following parameter values:

- ATQ_LRN_MIN_CURRENT = 1011000b

- ATQ_LRN_STEP = 00b

Values for the ATQ_LRN parameters are:

- ATQ_LRN_CONST1 = 43

- ATQ_LRN_CONST2 = 99

Figure 3-6 Learning Routine Snapshot for

Textile Motor

Figure 3-6 Learning Routine Snapshot for

Textile MotorThe parameters for current control and PD loop control were selected as:

- ATQ_TRQ_MAX = 216

- ATQ_TRQ_MIN = 80

- ATQ_UL = 13

- ATQ_LL = 12

- KP = 1

- KD = 15

- ATQ_D_THR = 7

- ATQ_ERROR_TRUNCATE = 0

- ATQ_FRZ = 1

- ATQ_AVG = 0

Figure 3-7 to Figure 3-10 showcase the output current and supply current waveforms with and without auto-torque in the event of a load torque change. As is expected, supply current consumption is significantly lower with auto-torque.

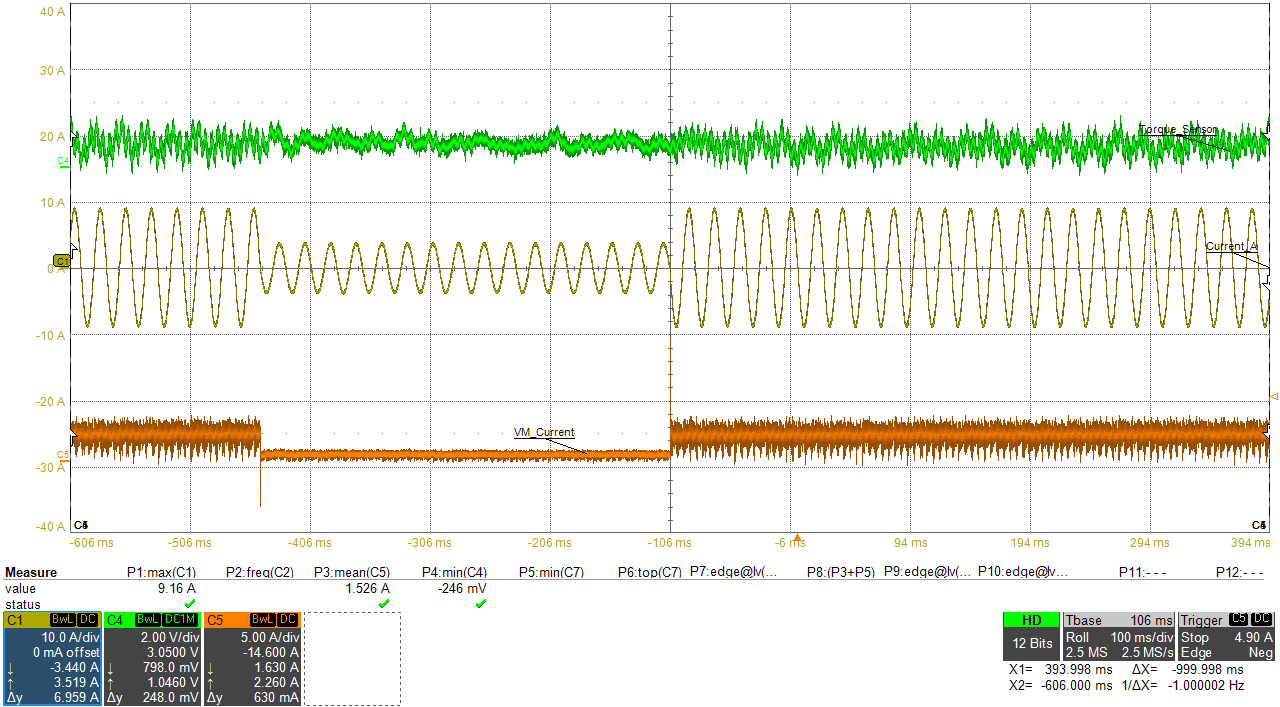

Figure 3-7 Textile

Motor Loading/Unloading Without Auto-Torque

Figure 3-7 Textile

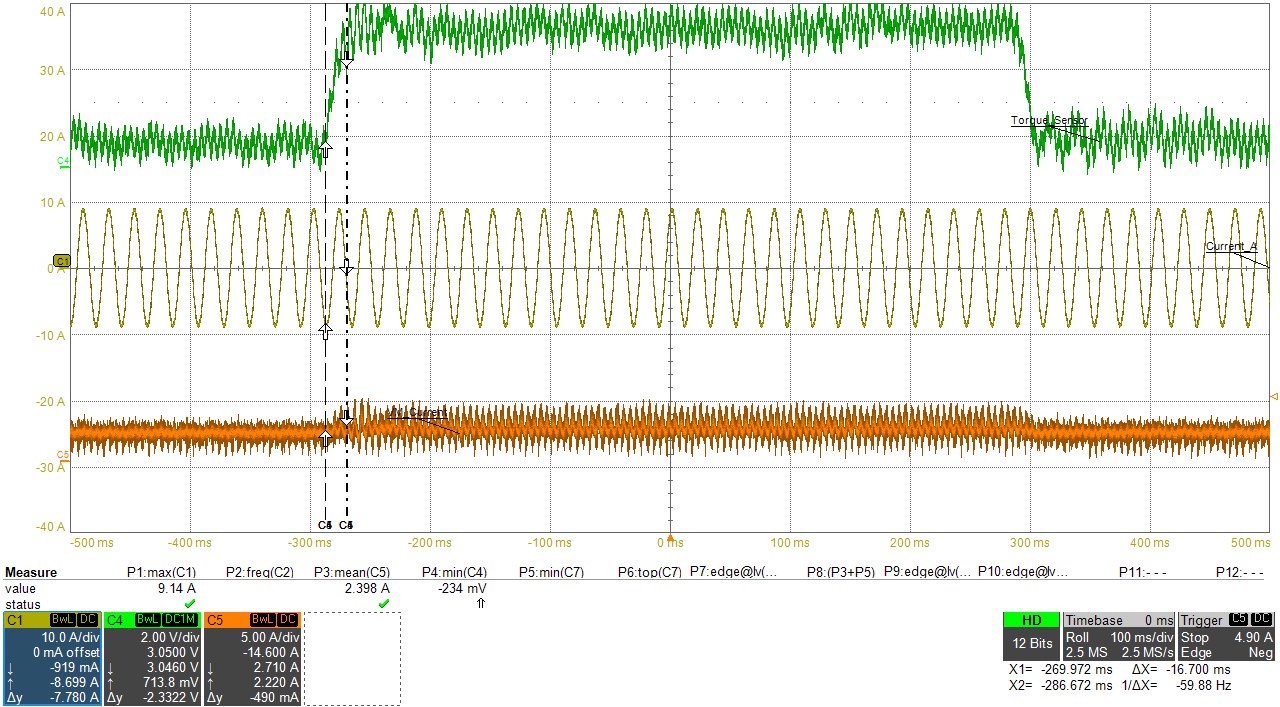

Motor Loading/Unloading Without Auto-Torque Figure 3-8 Textile

Motor Loading/Unloading Without Auto-Torque

Figure 3-8 Textile

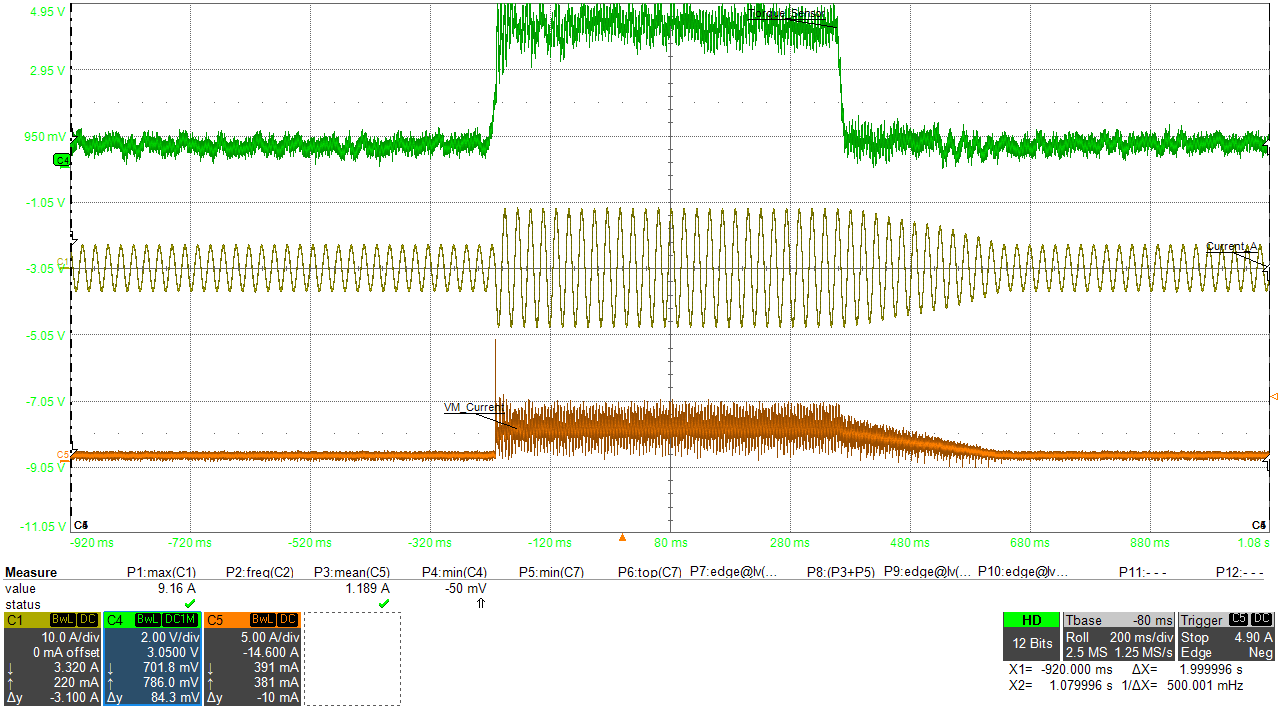

Motor Loading/Unloading Without Auto-Torque Figure 3-9 Textile

Motor Loading/Unloading With Auto-Torque

Figure 3-9 Textile

Motor Loading/Unloading With Auto-Torque Figure 3-10 Textile Motor

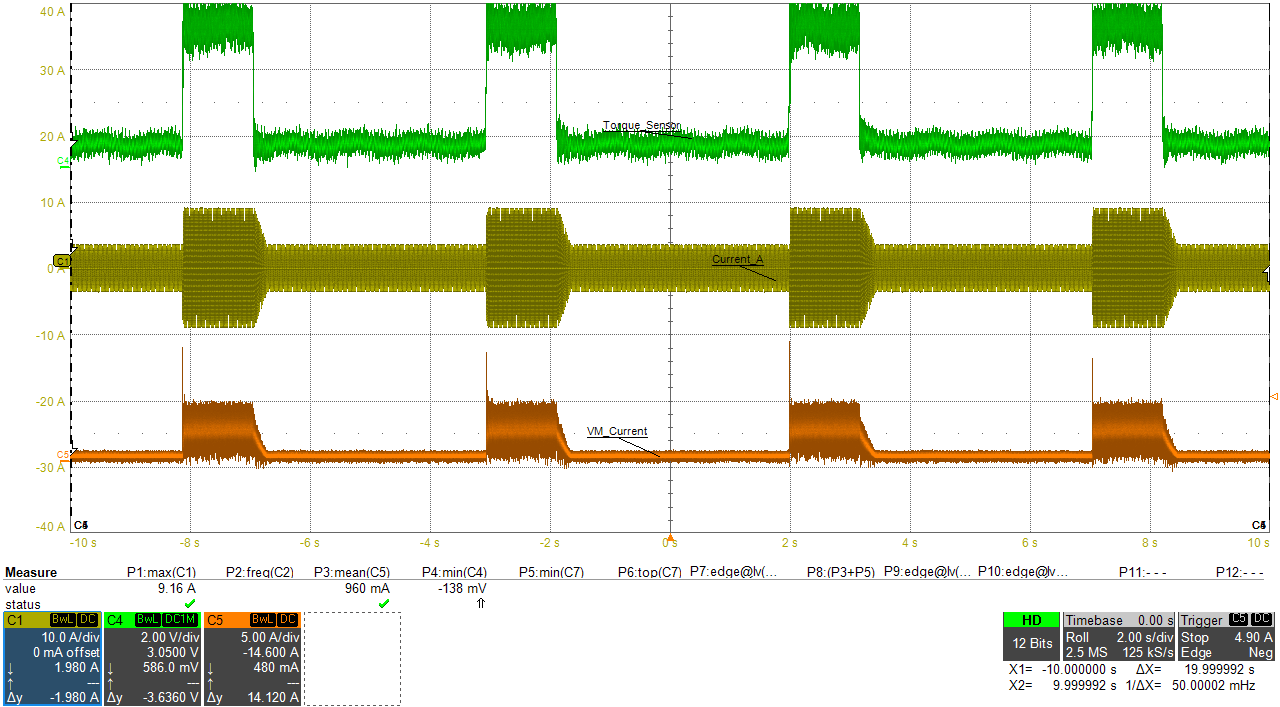

Loading/Unloading With Auto-Torque

Figure 3-10 Textile Motor

Loading/Unloading With Auto-TorqueBased on lab measurements:

- Power consumed without auto-torque = 24 V * 2.345 A = 56.28 W

- Power consumed with auto-torque = 24 V * 960 mA = 23.04 W

- This represents a power saving of 59 %.

- Power loss in the motor without auto-torque = (9 A * 9A * 0.15 Ω) = 12.15 W

- Power Loss in the motor with auto-torque = (0.2 * 9 A * 9 A + 0.8 * 3.6 A * 3.6 A) * 0.15 Ω = 4 W

- This corresponds to a heat reduction of 67 % in the motor coils.