SLVUCP8 September 2024 TPS26750

- 1

- Description

- Get Started

- Features

- Applications

- 6

- 1Evaluation Module Overview

- 2Hardware

-

3Software

- 3.1 Software Description

- 3.2 Software Installation

- 3.3 Software Development

- 3.4 Using the Application Customization Tool

- 4Application Specific Use Cases

- 5Hardware Design Files

- 6Additional Information

1.3 Specification

The functional block diagram of the TPS26750EVM is shown in Figure 1-1. This can be used as a standalone evaluation module to test sourcing 5V and sinking from 5V to 48V. Alternatively, the EVM can be used in conjunction with the BQ25756EVM to source and sink from 5V to 48V. The TPS26750EVM can test both USB-PD SPR (Standard Power Range) and USB-PD EPR power ranges, and can be configured using the Application Customization tool as a source only device, a sink only device, or a Dual Role Power (DRP) device.

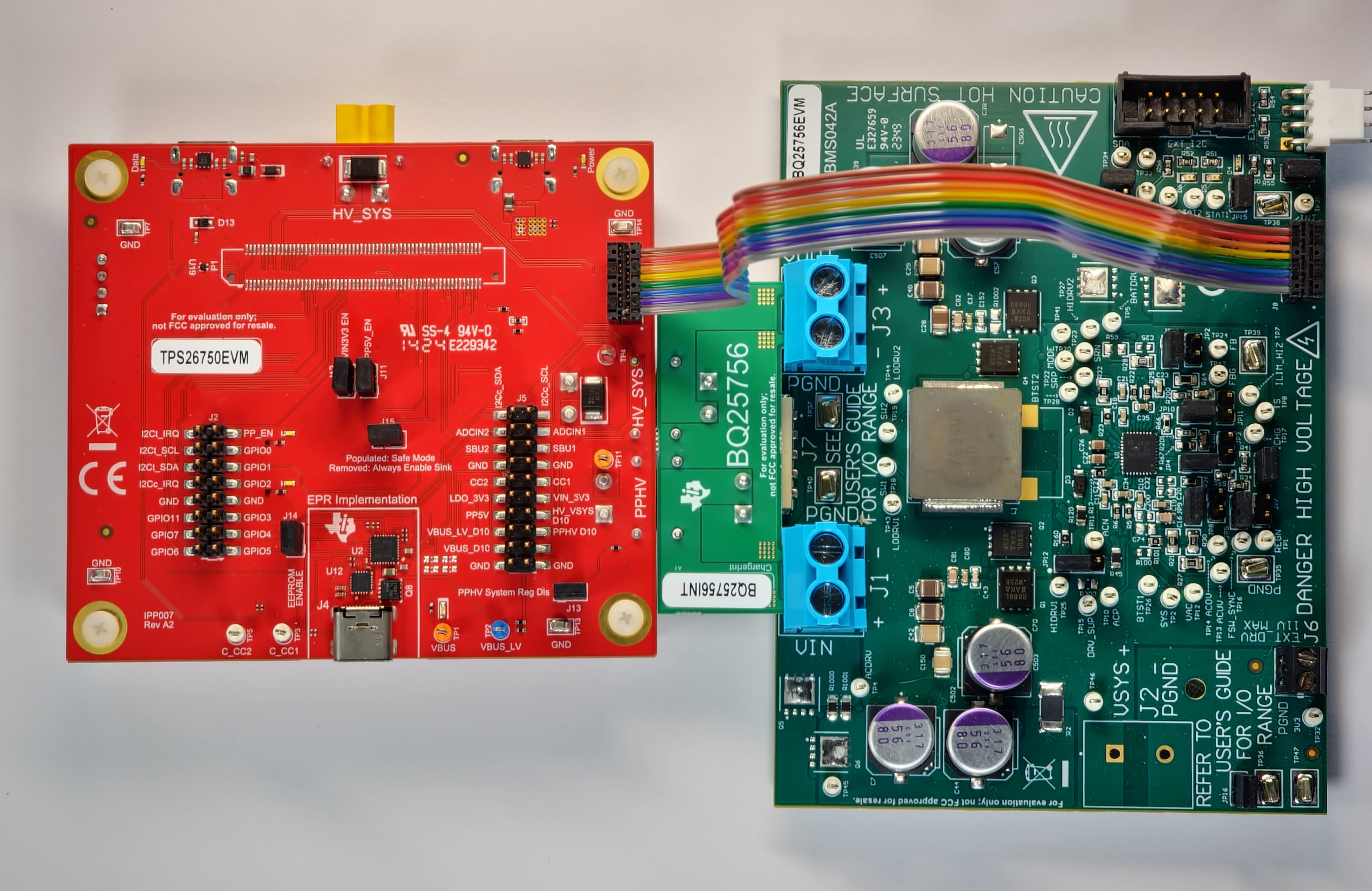

The TPS26750EVM can be used in conjunction with the BQ25756 with minimal setup to test battery charging by utilizing, as shown in Figure 1-2:

- TPS26750 and BQ25756 I2C capability

- The ability of the Application Customization GUI to configure the TPS26750 to work with the BQ25756 by selecting only a few parameters from a questionnaire

- The provided 4x2 IDC cable

- The BQ25756 connector board

Figure 1-2 TPS26750EVM and BQ25756EVM Hardware

Setup

Figure 1-2 TPS26750EVM and BQ25756EVM Hardware

Setup