SNLU342 December 2023 MCT8315Z

2.1 Quick Startup Guide

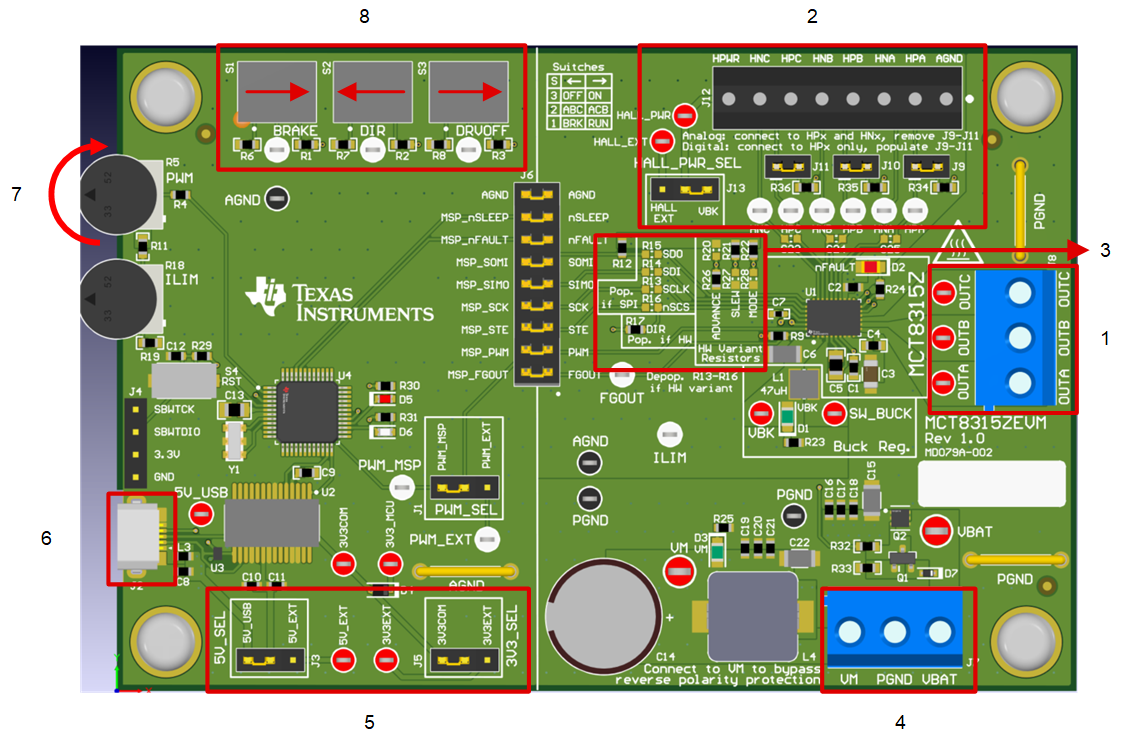

The MCT8315ZEVM requires a power supply source, which has a recommended operating range from 4.5 V to 35 V. To setup and power the EVM, follow the sequence below:

- Connect motor phases to A, B, and C on connector J8.

- Connect Hall sensors to J12 and select Hall power supply to come from VBK or an external Hall supply using J13.

- If using digital Hall inputs, then populate J9–J11 with shunt jumpers to enable pullups. Connect the single-ended inputs to only the HPx pins on connector J12. This is the default configuration of the MCT8315ZEVM.

- If using analog Hall inputs, then remove J9-J11 and connect differential Hall inputs to HPx and HNx on connector J12.

- If using the MCT8315ZH or MCT8315ZT, then make sure resistors are populated in HW variant resistors for desired device settings as described in Section 2.7.1.

- Do not turn on the power supply yet. Connect the motor supply to VBAT or VM and PGND on connector J7.

- To enable the reverse polarity protection and Pi filter, connect to VBAT. Note that when connecting to VBAT, VM is VM – 0.7 V less due to a diode drop in the reverse-polarity protection circuit.

- To disable the reverse-polarity protection and the Pi filter, connect to VM.

- Select J3 to 5V_USB and J5 to 3V3COM to power MSP430 from USB power supply.

- Connect the micro-USB cable into the computer.

- Turn the R5 potentiometer fully clockwise to set the motor to zero speed upon power up.

- Flip the switch S1 to the right to configure BRAKE = RUN, switch S2 to the left to configure DIR = ABC, switch S3 to the right to configure DRVOFF = ON.

- Turn on the motor power supply.

- Use the R5 potentiometer to control the speed of the motor, the R18 potentiometer to control the cycle-by-cycle current limit, and the switches to disable the motor driver, change the motor's direction, or brake the motor. Optionally, use the MCF8315Z GUI, refer to Section 3.1, to monitor the real-time speed of the motor, put the MCT8315Z into a low-power sleep mode, and read status of the EVMs LEDs.

Figure 2-1 Reference for Quick Start Guide

Figure 2-1 Reference for Quick Start Guide