SSZT056 october 2022 MCF8315A , MCF8316A , MCT8315A

The previous installment in the real-time control series dove into the functional block of processing. In this installment, I will discuss the actuation stage (updating the system) of real-time control, and why this stage is important for reliable system output operation.

For example, in motor-drive applications, you might be monitoring and measuring speed, position, torque and motor health in real time in order to start, accelerate or modulate the dynamic speed, or decelerate the motor system. Similarly, in semiconductor or battery test equipment, you can use digital-to-analog converters to send accurate analog signals in a fast control loop way, adjusting the output power of a gallium nitride (GaN)-based server power-supply unit (PSU) at different load conditions, or gate drivers driving metal-oxide semiconductor field-effect transistors (MOSFETs) in uninterruptible power supplies during power interruptions. In all examples, it’s extremely important to modulate and adjust the actuation (for applications such as a motor drive, battery test equipment or power-supply unit) for a real-time control system.

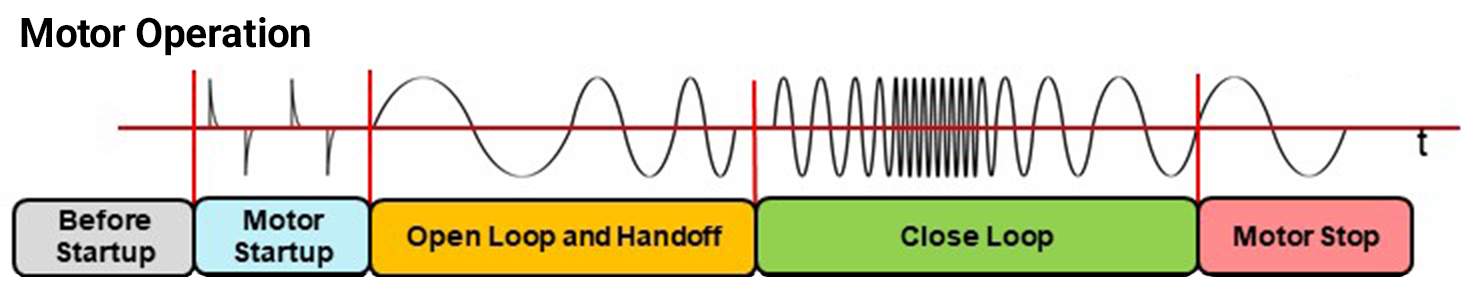

During motor operation, there are different stages happening that help enable reliable motor actuation. The stages of a motor include pre-startup, motor startup, open loop, closed loop and motor stop. The closed-loop stage provides accurate real-time feedback to the system, as it is constantly monitoring different variables and then actuating in a closed-loop response manner, as shown in Figure 1.

Figure 1 Motor Operation Stages

Figure 1 Motor Operation StagesHigh Efficiency

As electrification continues to increase, there are more energy-efficiency standards across multiple appliances and applications: Energy Star, 80 Plus, the ErP Lot 9 standard and others. Therefore, it’s important to maintain the highest efficiency in your real-time control system in order to enable lower power consumption and system effort during rapid changes. A very efficient system enables faster response, a lower cost of ownership and longer lifetimes.

For example, a vacuum robot needs to maximize the floor coverage for each trip based on the battery charge. It can do so by adjusting the suction power in real time as it detects changes in floor material or debris level, or if an object gets stuck in the robot. The vacuum suction motor – driven by a brushless-DC (BLDC) motor driver – needs to be as efficient as possible, since it has multiple sources of power dissipation, such as switching losses, the drain-to-source on-resistance RDS(on) and the slew rate of the MOSFET. It is possible to decrease these sources with techniques such as increasing the slew rate, decreasing the pulse-width modulation (PWM) output frequency, using lower RDS(on) MOSFETs to drive the motor, or using different PWM modulation modes such as single-ended.

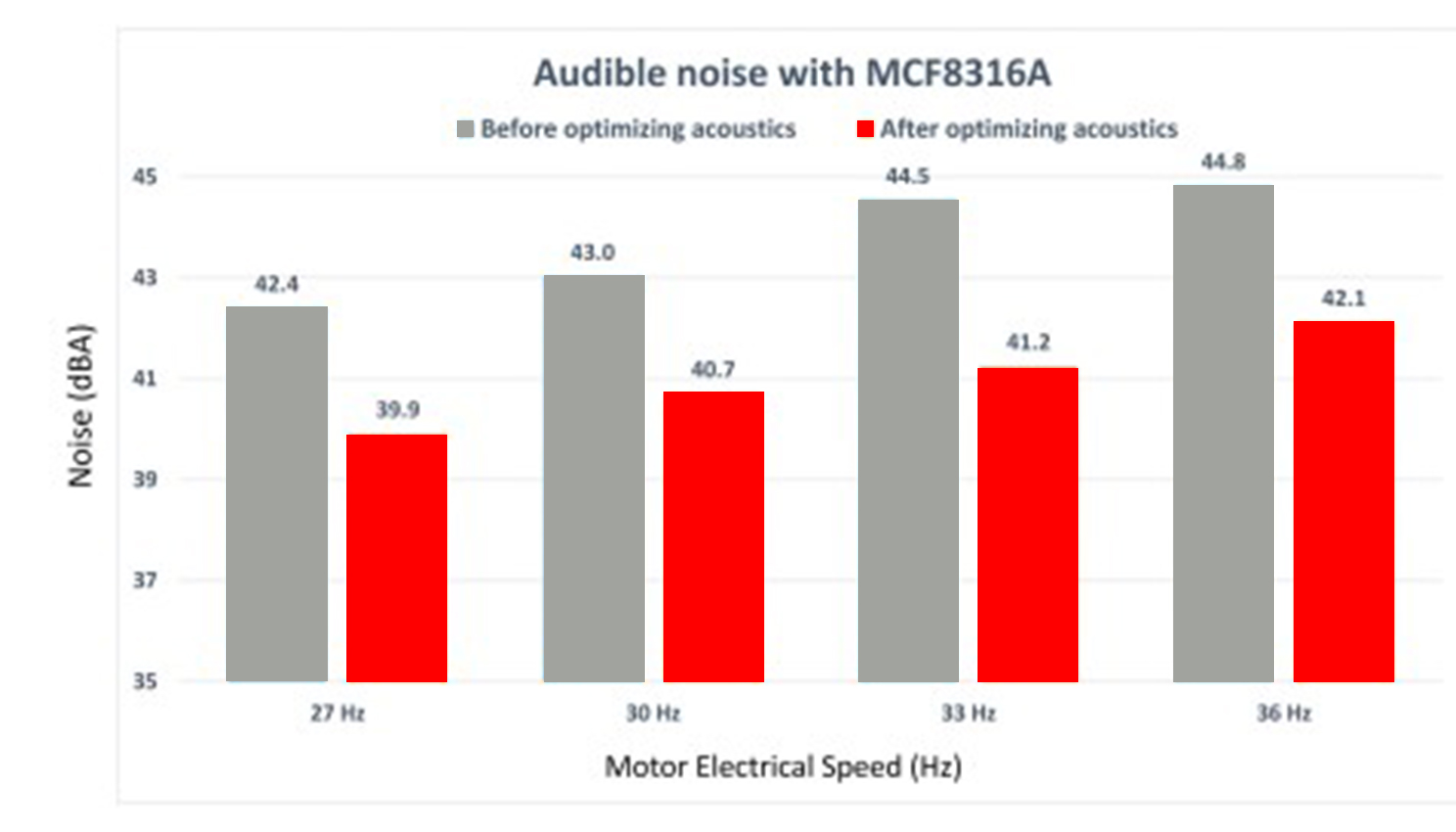

Consumers purchasing white goods appliances prefer quieter systems. BLDC motor drivers are enabling better acoustic performance with control techniques such as sinusoidal, and most recently with field-oriented control (FOC), which allow you to achieve the best motor efficiency by maintaining fluxes at 90 degrees. TI’s single-chip code-free sensorless MCF8316A BLDC motor driver enables system designers to minimize audible noise through control techniques such as continuous PWM modulation, dead-time compensation and a variable commutation mode.

Figure 2 compares audible noise with the MCF8316A before and after optimizing acoustics.

Figure 2 Audible Noise Comparison with

the MCF8316A

Figure 2 Audible Noise Comparison with

the MCF8316AReliability

Real-time control system protection mechanisms provide reliable operation in harsh and unpredictable environments, such as hot and cold temperatures, or where external factors might electrically or even physically influence the system. Take an example where a system might have moving parts, such as a motor drive. The ability to detect or predict rotor lock can help minimize power loss, device failure or damage. TI’s MCF8316A continuously checks for different motor lock conditions during motor operation and takes immediate action when detecting a lock event. One real-world actuation example is when a vacuum robot detects an object such as a washcloth stuck in its path. The system load spikes up, which the system determines is a motor lock condition, and the motor is able to spin in the opposite direction to unravel the object and continue normal operation.

A code-free motor driver such as the MCF8316A or MCF8315A also manages critical functions, such as motor fault detection, and implements protection mechanisms to make the overall system design more reliable.

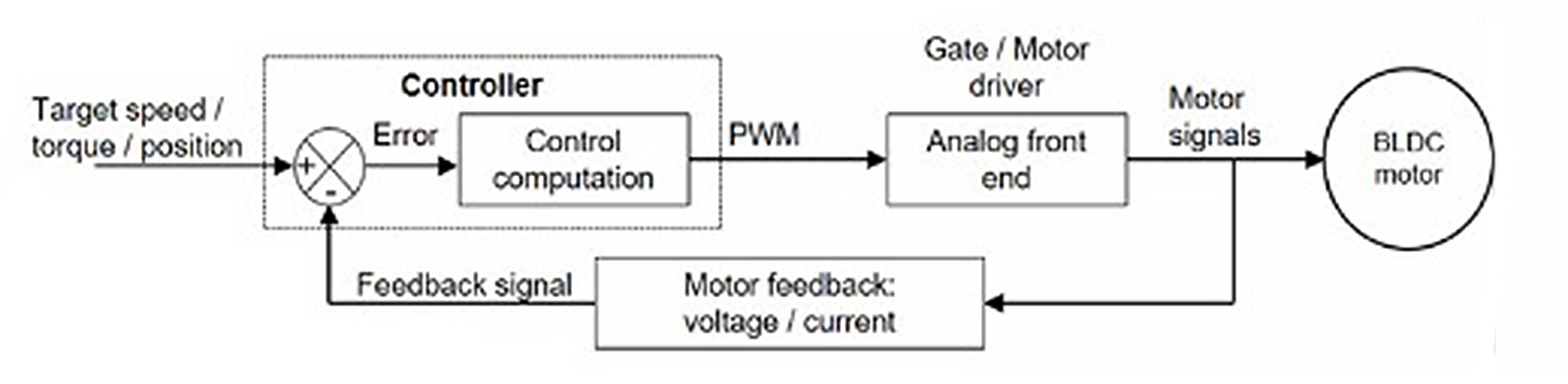

Figure 3 is a block diagram of a typical BLDC real-time control motor system where voltage and current sense resistors constantly provide motor feedback (based on the protection mechanisms) to the controller, which sends different PWM signals to the motor driver in order to actuate accordingly.

Figure 3 A Sensorless BLDC Real-time

Control Motor System

Figure 3 A Sensorless BLDC Real-time

Control Motor SystemAccuracy

Real-time control system accuracy is very important for reliable operation. A typical motor closed-loop system relies on the processing speed of the drivers to have the highest speed accuracy with minimum latency. Also, in real-time control systems where you need to provide closed-loop feedback, current-sense amplifiers provide the highest levels of current-sensing accuracy across a broad range of common-mode voltages and temperatures.

In applications such as a continuous positive airway pressure (CPAP) machine for people with sleep apnea, an accurate real-time control system constantly monitors for air blockages and delivers necessary air to open a person’s airways. Another example is DLP® projector applications that requires high-speed accuracy (1%) for the color-wheel motor system in order for the projector to display high-quality color images to the screen in end equipment such as home theater projectors, as shown in Figure 4.

Figure 4 DLP Home Theater

Projector

Figure 4 DLP Home Theater

ProjectorConclusion

The actuation stage of a real-time control system depends on the different types of feedback from the sensing stage constantly monitoring any change in system conditions, which are then sent over to the control stage to interpret the data and send the next actuation command. Whether the value proposition is minimizing audible noise through dead-time compensation, providing motor lock detection features or providing accurate speed, BLDC motor drivers are playing an important role in the actuation piece of many industrial and automotive applications.

To learn more about the communications functional block of real-time control, read the technical article "How IT/OT convergence in real-time control and communications is advancing industrial automation."