-

Simplifying Radiation-hardened Power-supply Design with eFuses SSZT277 july 2020 TPS7H2201-SP , TPS7H2211-SP

-

Simplifying Radiation-hardened Power-supply Design with eFuses

Simplifying Radiation-hardened Power-supply Design with eFuses

Sree Alvarado

Today’s satellites use complex, high-power field-programmable gate arrays (FPGAs) and processors, challenging power-supply design engineers to create robust power supplies. Many designers end up with complicated designs meant to achieve redundancy (the duplication of critical components to increase reliability), involving dozens of discrete components like field-effect transistors (FETs) to continuously monitor and enable specific power rails.

Since not all of these high-power devices will be on all the time, the ability to turn the power to the payload or processor on and off can not only help simplify designs but also lower power consumption. In addition, if a latch-up or a transient occurs in a power device, power-supply designers have to consider how to contain that failure until power can be restored to that rail, or have a redundant power rail take over.

Using an eFuse to simplify your design

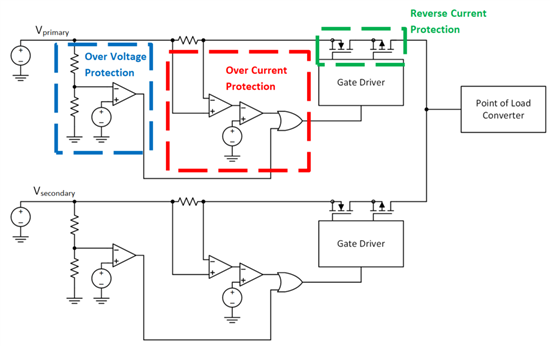

Discrete metal-oxide semiconductor FETs (MOSFETs), comparators, amplifiers and references that provide input power to the satellite payload are just some examples of devices that are needed to achieve redundant inputs to the satellite payload, with appropriate monitoring and protection. This type of power-supply design implementation results in larger solutions with many potential radiation and electrical failure points. Figure 1 shows an example of such a complex implementation.

Figure 1 Discrete implementation of a load-switch redundancy application with reverse-current protection, overvoltage protection and overcurrent protection

Figure 1 Discrete implementation of a load-switch redundancy application with reverse-current protection, overvoltage protection and overcurrent protectionAn eFuse like the TPS7H2201-SP load switch has additional monitoring and protection features like reverse-current protection, over- and undervoltage protection, programmable current limiting, fault timer, and configurable rise time. It can reduce complex designs down to a single monolithic, radiation-hardened device.

Redundancy

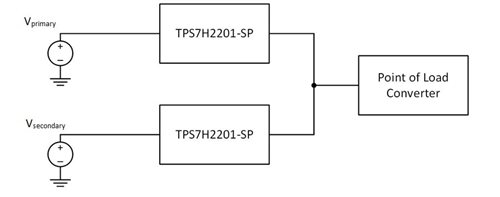

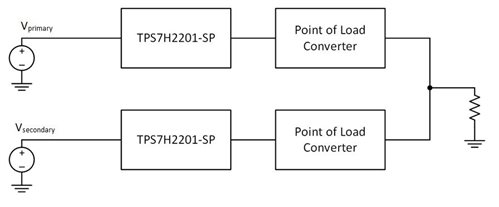

In the event of a complete failure, if there are two fully autonomous power supplies, an eFuse can enable one power supply and turn off the other. This configuration is known as redundancy, and provides protection for both downstream and upstream components. Figure 2 and Figure 3 show different implementations of cold sparing.

Figure 2 Redundant input voltages with the TPS7H2201-SP eFuse, including RCP, OVP, OCP, and automatic reset of a tripped power rail

Figure 2 Redundant input voltages with the TPS7H2201-SP eFuse, including RCP, OVP, OCP, and automatic reset of a tripped power rail Figure 3 Redundant input and output voltages with eFuse, including RCP, OVP, OCP, and automatic reset of a tripped power rail

Figure 3 Redundant input and output voltages with eFuse, including RCP, OVP, OCP, and automatic reset of a tripped power railWhile it is possible to achieve simple on/off functionality with a MOSFET controlled by a processor, a critical component for reliable operation is the reverse-current protection. Reverse current (VOUT > VIN) can occur in cold sparing applications when the secondary switch is off. A design with two FETs back to back can protect against the reverse current propagating to upstream components. TI’s TPS7H2201-SP dual-FET design allows for reverse-current protection when the device is enabled or disabled, a necessary feature for a highly reliable point-of-load power design. Other discrete or integrated load switch solutions available on the market may use a single FET design, and are limited in reverse-current protection capability.

Failure containment

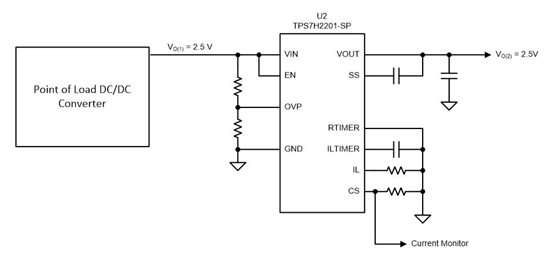

To ensure a power-supply design with dependable performance, another key design consideration is failure containment. The goal of failure containment is to prevent a random failure (like a short circuit or radiation-caused transient) from propagating to downstream components (like an FPGA, data converter or interface device). Placing an integrated eFuse downstream from a critical power component (Figure 4) can help contain failures. An eFuse with programmable current and voltage limits will help enable the detection of overvoltage or overcurrent events so that they do not propagate to downstream components.

Figure 4 Downstream eFuse with overvoltage protection

Figure 4 Downstream eFuse with overvoltage protectionConclusion

Adding functionality to monitor critical payload power components (like a DC/DC converter) and planning for failure with redundancy for input components can help ensure a power supply that can withstand harsh environments. Instead of complex circuitry with several active components and increased processor involvement, devices such as the TPS7H2201-SP integrate the functionality of the switch FETs, overvoltage protection circuitry, overcurrent protection circuitry, reverse-current production circuitry, and programmable voltage and current limits in a single device. Additionally, the Qualified Manufacturers List Class V-radiation-hardness-assured eFuse is fully characterized for low-earth-, medium-earth- and geosynchronous-orbit missions.

Additional resources:

- For more information on failure containment, read the application report, “Failure Containment in Spacecraft Point-of-Load Power Supplies.”

- Check out the technical article, “When failure isn’t an option: power up your next satellite with integrated functionality and protection.”

- To learn more about the radiation performance of the TP7H2201, see these reports:

IMPORTANT NOTICE AND DISCLAIMER

TI PROVIDES TECHNICAL AND RELIABILITY DATA (INCLUDING DATASHEETS), DESIGN RESOURCES (INCLUDING REFERENCE DESIGNS), APPLICATION OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND OTHER RESOURCES “AS IS” AND WITH ALL FAULTS, AND DISCLAIMS ALL WARRANTIES, EXPRESS AND IMPLIED, INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT OF THIRD PARTY INTELLECTUAL PROPERTY RIGHTS.

These resources are intended for skilled developers designing with TI products. You are solely responsible for (1) selecting the appropriate TI products for your application, (2) designing, validating and testing your application, and (3) ensuring your application meets applicable standards, and any other safety, security, or other requirements. These resources are subject to change without notice. TI grants you permission to use these resources only for development of an application that uses the TI products described in the resource. Other reproduction and display of these resources is prohibited. No license is granted to any other TI intellectual property right or to any third party intellectual property right. TI disclaims responsibility for, and you will fully indemnify TI and its representatives against, any claims, damages, costs, losses, and liabilities arising out of your use of these resources.

TI’s products are provided subject to TI’s Terms of Sale (www.ti.com/legal/termsofsale.html) or other applicable terms available either on ti.com or provided in conjunction with such TI products. TI’s provision of these resources does not expand or otherwise alter TI’s applicable warranties or warranty disclaimers for TI products.

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2023, Texas Instruments Incorporated