-

Don’t Limit Your Audio: How to Achieve Loud Sound from a Small Speaker

Don’t Limit Your Audio: How to Achieve Loud Sound from a Small Speaker

Matthew Kucic

One common challenge audio design engineers run into today is getting loud audio from a small speaker in systems with a single cell battery. The best solution is to give the amplifier more power. In portable electronic devices, implementing a Class-D audio amplifier with a boost will deliver that extra power.

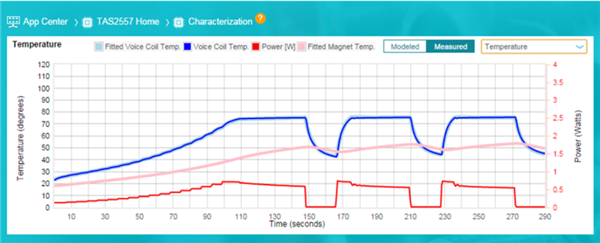

Unfortunately, the power needed to achieve high sound pressure levels (SPLs) will often exceed the continuous power rating of smaller speakers. These speakers have a heating time constant (shown in Figure 1) that allows for an exceeded continuous power level – but only for a brief period of time. If the power level doesn’t quickly return to its normal level, the speaker can become damaged.

Figure 1 Speaker Coil Heating Time Constant

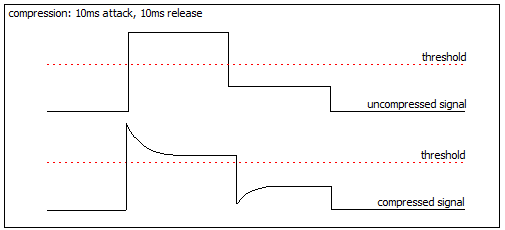

Figure 1 Speaker Coil Heating Time ConstantOne solution to this design challenge is to use a limiter: with such an implementation, the amplifier will allow for peaks but prevent sustained power delivery to the speaker. Although limiters are simple to use and cost-effective, they can introduce audio artifacts. If you know the speaker’s continuous power level (its thermal time constant) and its impedance, you can properly configure an output voltage limiter to push the audio output higher while helping to protect the speaker. The peaks will be allowed through (as shown in Figure 2), but with short time constants that match the speaker coil heating.

You can implement this simple feedforward-only solution either in the amplifier or upstream in the applications processor. Since there is no feedback, this method requires a considerable amount of headroom and design margin. The headroom must account for speaker-to-speaker manufacturing variations in heating time constants and varying ambient temperature conditions. Additionally, with minimal thermal headroom in the speaker coil, even short peak power delivered poses a risk of the speaker overheating as the ambient air temperature increases.

Figure 2 Limiter Peak Audio

Figure 2 Limiter Peak AudioTo push the speaker closer to its actual limits and drive louder audio, you will need to take advantage of an IV-sense Class-D amplifier or a Smart Amp. A Smart Amp’s speaker protection uses voltage and current feedback to measure the exact coil temperature from the changes in the speaker’s impedance over temperature. With a Smart Amp, you can remove the headroom in the feedforward-limiter solution and deliver peak power to the speaker until it reaches its actual thermal limit. When the speaker reaches this thermal limit, a Smart Amp will use compressors to begin controlling the peak audio.

You can also calibrate out the speaker-to-speaker variance, making sure that each speaker achieves its peak performance. A high ambient air temperature is also not a problem, since a Smart Amp extracts the exact speaker coil temperature. The headroom required during overdrive in the limiter is removed using the feedback from the speaker.

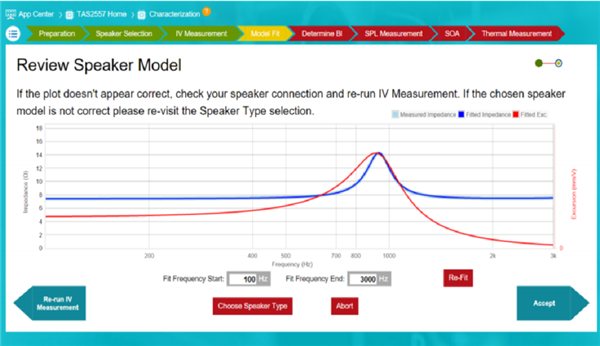

A limiter implementation does not use any advanced modeling of the speaker displacement (see Figure 3) and cannot protect from overexcursion. The limiter relies on proper equalization to prevent overexcursion of the speaker. The Smart Amp protection solution uses models of the speaker excursion updated in real time to protect the speaker from overexcursion. Using current and voltage sensing enables the system to extract the physical speaker parameters during operation. As the speaker nears the excursion limit, the system reacts to prevent overexcursion.

Figure 3 Speaker Excursion and Impedance Model

Figure 3 Speaker Excursion and Impedance ModelAlthough a simpler limiter protection implementation can result in audio louder than a conventional audio amplifier, its true effectiveness will be limited after accounting for all variations in individual speaker parameters. Additionally, there are still risks of speaker damage through overheating with high ambient temperatures and no overexcursion protection. TI Smart Amp products like the TAS2557, with advanced audio protection and tuning, enable you to extract every ounce of SPL from your speakers. Additionally, TI’s Pure Path™ Console 3 software for Smart Amp provides an intuitive interface for characterizing and tuning speakers for beginning to advanced audio engineers.

Additional Resources

- Learn how to begin your audio design with the application report, “Smart Amp Quick Start Guide.”

- Start prototyping quickly with the TAS2557 evaluation module.

- Read about tuning basics in the application report, “Smart Amp Tuning Guide.”

- Learn about system integration flow with the application report, “TAS2557 and TAS2559 End System Integration Guide.”

- Download the application report, “TAS2555, TAS2557 and TAS2559 Factory Test and Calibration Guide” for production-line best practices.