SSZTD36 June 2024 TMS320F280039 , TMS320F28P550SJ , UCD3138A

The demands of high-voltage systems have evolved significantly, driven by the need for increased power levels and the growing complexity of modern power systems. Meeting these demands effectively necessitates a real-time MCU or digital power controller capable of controlling advanced power topologies optimized for nuanced specifications and various power requirements simultaneously. This article will discuss a few benefits of digital power control in high-voltage applications and demonstrate how it facilitates the safe and efficient operation of advanced power systems.

Increasing system reliability and protecting power electronics

Reliability is crucial for high-voltage systems to ensure consistent operation. Reliable protection of power electronics from over-voltage, over-current, and thermal stress extends component lifespan, enhances safety, reduces maintenance costs, and minimizes downtime, ensuring efficient and effective performance without unexpected failures.

The cheap and simple discrete analog products of the past lack the necessary flexibility and robustness to be used in scale especially in rapidly growing vectors like hybrid and electric vehicle, energy infrastructure and power delivery that have increasing requirements for high voltage power electronics.

So, digital power offers greater capability in terms of power toplogy options, system level features and protections, while minimizing the total number of designers that must be allocated to get projects out of the prototype stage and into production.

Real-time MCUs and digital isolated power controllers enhance reliability in such systems. They minimize latency between sensing and action, ensuring swift and accurate responses to load changes and disturbances. This improves stability, reduces susceptibility to transient events, and boosts overall performance.

MCUs and digital power controllers also protect power electronics by swiftly detecting faults such as overcurrent, overvoltage and overtemperature, and triggering immediate protective measures. They offer precise control over power switching and modulation techniques, optimizing FET performance within safe limits and minimizing component stress.

Capable of controlling multiple power stages simultaneously

The increased power levels and complexity of modern high-voltage systems often mean there are multiple power stages running within one system. This requires a capable real-time MCU or digital controller to control all of them simultaneously.

One example is a microinverter for solar energy applications. A typical microinverter system involves multiple power stages, including DC/DC stages converting electrical power generated by solar panels to a high DC bus voltage, and then converting DC power into AC power for the grid. TI’s C2000™ real-time MCUs can drive the power stages while providing advanced monitoring and housekeeping functions. The 1.6kW Bidirectional Microinverter Based on GAN Reference Design includes a TMS320F280039C MCU capable of handling all four DC/DC boost stages, plus a converter-inductor-inductor-inductor-converter and a single-phase totem-pole power factor corrector (PFC). The new TMS320F28P550SJ is capable of supporting six or more photovoltaic panels, thanks to increased computational power, up to 24 pulse-width modulation channels, and 39 analog-to-digital converter channels.

TI’s digital power controllers like UCD3138A are used to control multiple stages simultaneously. One example is Power Factor Correction (PFC) in an AC-DC application like a server PSU. Another example is HV DC-to-DC converters for telecom power such as 48V or 12V. To implement many variants across power levels and regions, experienced designers using discrete analog controllers must recalculate, test, and validate their work. With digital power controllers, one device may control the entire system, and changing parameters like voltage and current thresholds across projects can occur mostly in firmware, saving the engineering team’s limited time. In addition, digital power controllers offer additional flexibility, communications, and housekeeping functions. To operate increasingly sophisticated power stages with the highest reliability and scalability, digital power controllers and real-time MCUs offer multiple options across end equipment requiring high-voltage FETs.

Maximizing investment in software and hardware solutions

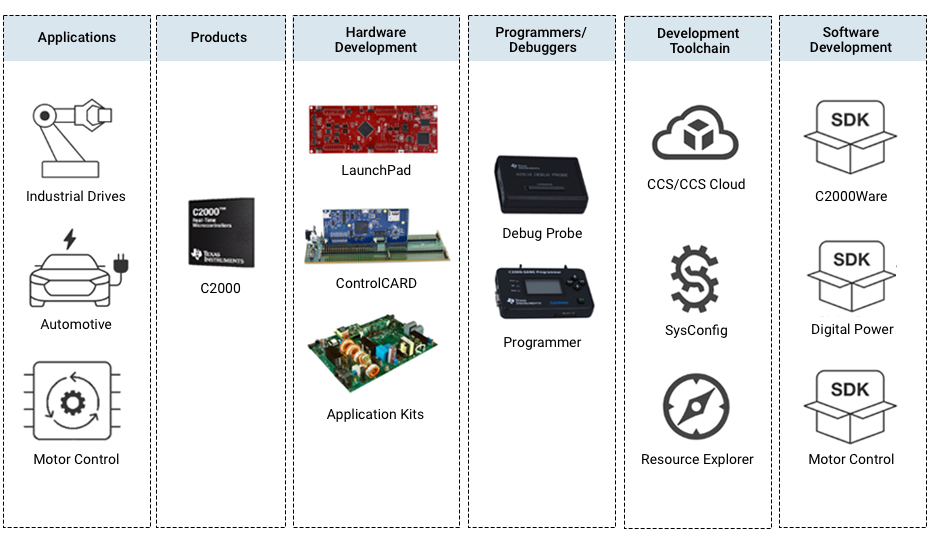

In today’s high-voltage systems, there is a growing need for redundancy, compliance with international standards, and relying less on external parties for engineering design activities. A scalable platform should support a wide range of designs with compatible hardware and software. TI offers resources such as reference designs, evaluation modules, and debuggers and programs that facilitate faster evaluation of digital power controllers and MCUs across different applications, reducing the need for custom board development. TI also provides software libraries and firmware examples for different system configurations, speeding up prototyping and software development. GUI tools such as Fusion Digital Power™ Studio enable quick tuning and optimization of parameters that would typically require external components, along with supporting device programming for both prototyping and production.

A summary of resources offered in UCD3138A ecosystem is provided in Figure 1.

Figure 1 Ecosystem of UCD3138A digital

power controllers

Figure 1 Ecosystem of UCD3138A digital

power controllersFigure 2 shows the ecosystem of C2000 real-time MCUs composed of various applications, products, hardware platforms, development tools, and software development kits.

Figure 2 Ecosystem of C2000 real-time

MCUs

Figure 2 Ecosystem of C2000 real-time

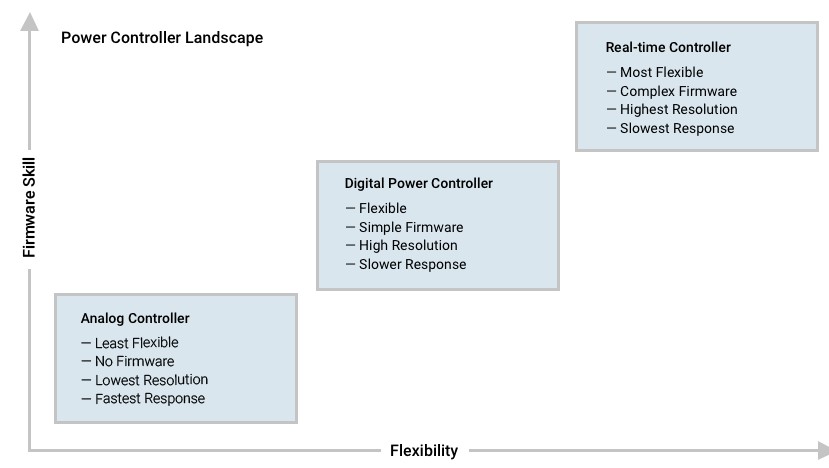

MCUsWhen to consider a digital power controller versus a real-time MCU

Consider a digital power controller:

- When your design requires the flexibility and housekeeping of digital, without the need to fully customize the power supply control law while leveraging digital power peripherals with dedicated feedback loops for higher bandwidth

- For applications preferring tuning and optimization of parameters thorugh a GUI instead of strictly firmware development for ease of use.

- When ARM core optimized for power supply control is preferred with dual memory bank for easy live firmware update for zero down-time.

Consider a real-time MCU:

- When your design requires precise, adaptive control and rapid response to system conditions, such as in dynamic grid-tied inverters or motor drives.

- For applications requiring complex algorithm execution, such as advanced modulation techniques or predictive control strategies.

- When seamless integration with peripheral devices, communication interfaces or complex system diagnostics are necessary for comprehensive system monitoring and control.

The aforementioned points are summarized in Figure 3, also see digital power technologies page on TI.com.

Figure 3 TI power controller

landscape

Figure 3 TI power controller

landscapeConclusion

Building a more sustainable future hinges on the growth of high-voltage applications such as electric vehicles, bidirectional energy harvesting and storage systems, and more efficient data centers, which require advanced multilevel protection schemes to deliver on their full potential.

With TI’s portfolio of high-voltage real-time control technologies, you can control multiple power stages simultaneously and reliably, with flexibility and the ecosystem to maximize intellectual property usage from project to project.

Additional resources

- Read these application notes:

Trademarks

All trademarks are the property of their respective owners.