-

Traction Inverters – A Driving Force Behind Vehicle Electrification SLYY217 September 2022 AM2631 , AM2631-Q1 , AM2632 , AM2632-Q1 , AM2634 , AM2634-Q1 , UCC14130-Q1 , UCC14131-Q1 , UCC14140-Q1 , UCC14141-Q1 , UCC14240-Q1 , UCC14241-Q1 , UCC14340-Q1 , UCC14341-Q1 , UCC15240-Q1 , UCC15241-Q1 , UCC5870-Q1 , UCC5871-Q1 , UCC5880-Q1 , UCC5881-Q1

-

Traction Inverters – A Driving Force Behind Vehicle Electrification

Traction Inverters – A Driving Force Behind Vehicle Electrification

At a glance

Traction inverter design trends and relevant semiconductor technologies and components are discussed in depth.

Understand the trends currently enabling high-performance, efficient and

reliable traction inverter systems. | |

Learn why the current-sensing feedback loop has such an effect on vehicle

speed and performance. | |

Silicon carbide (SiC) metal-oxide semiconductor field-effect transistors

(MOSFETs) and high voltages, when paired with the right components, improve

the EV driving experience. |

Authors

Exploring EV traction inverter design trends

A traction inverter converts battery energy into power that controls torque and speed, giving it the most influence over an EV’s range, performance and driving experience. Torque is proportional to motor size, while power provides torque and speed. Keeping power constant, if you want to reduce the motor size and torque, you need to increase the speed. This is a challenge, as component sizes typically increase with power level and torque, especially if there are design inefficiencies such as losses from mechanical or electrical nonidealities. It becomes important, then, to reduce not only the size of the motor, but also the electrical system to the traction inverter itself.

In order to extend driving range and reduce motor size and weight without compromising the power level, a traction motor needs to be able to run at higher speeds (>30,000 rpm). This requires fast sensing and processing, as well as the efficient conversion of DC to AC voltages. To achieve these goals, traction inverter design trends include using advanced control algorithms, employing SiC MOSFETs for the switching transistors in the power stage, using high-voltage 800-V batteries and integrating multiple subsystems to obtain high power densities.

Driving efficiency with fast current-sensing feedback loops and high-speed controllers

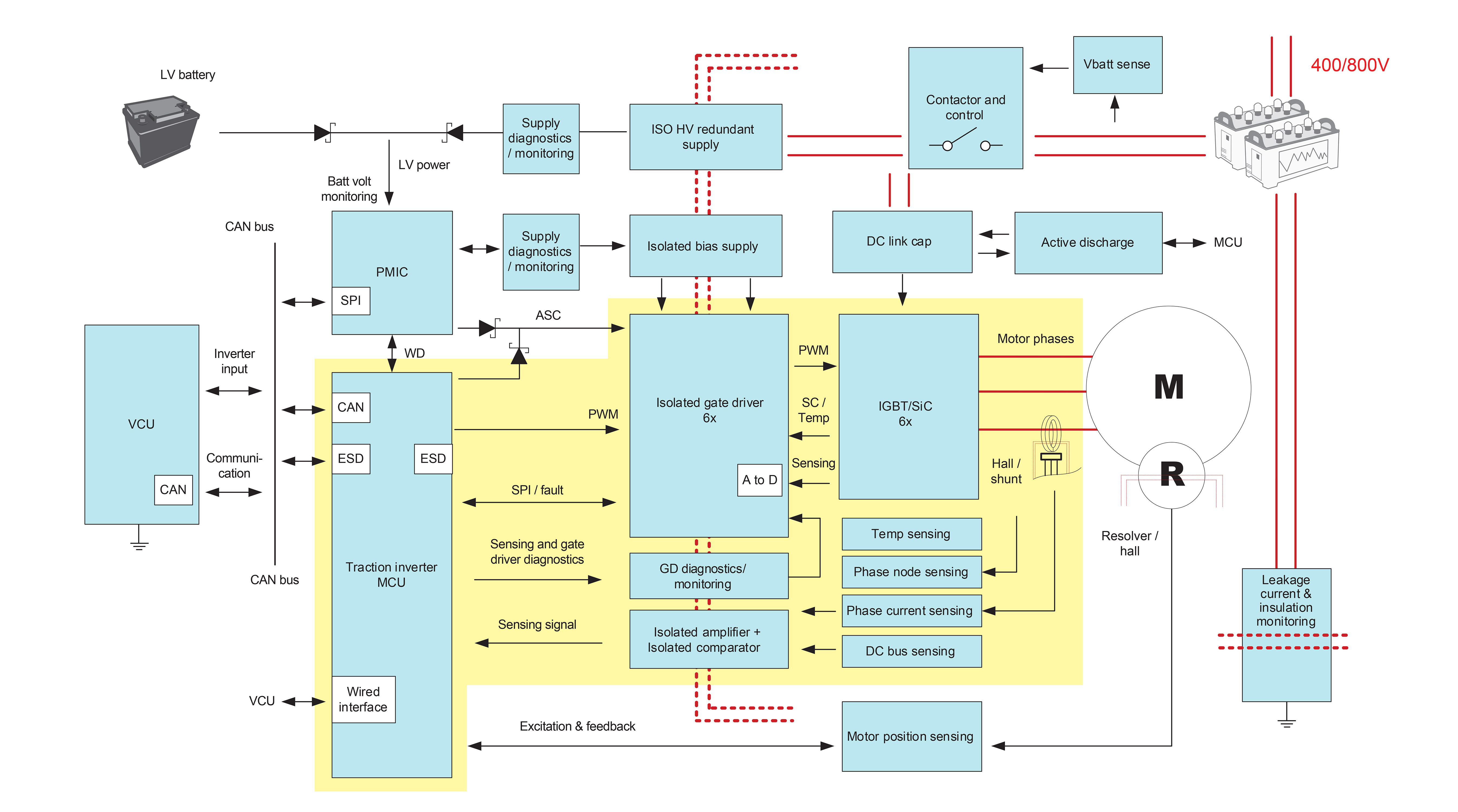

One way to improve the EV driving experience, which includes steady cruise control, responsive acceleration and deceleration, and a quieter cabin experience, is to improve the overall accuracy and reliability of the current-sensing feedback loop. This control loop is the pathway that the sensed currents take from the output of the traction inverter’s phases, back through isolated precision amplifiers and through the microcontroller (MCU) for processing. This journey finally results in the signals that come back to the control output of the traction inverter. Optimizing the motor-control loop enables fast and precise feedback so that the motor can react quickly to changes in speed or torque. The highlighted portion in Figure 1 shows the motor-control loop.

Figure 1 Traction inverter block

diagram, with the motor-control loop and power stage highlighted in

yellow.

Figure 1 Traction inverter block

diagram, with the motor-control loop and power stage highlighted in

yellow.As detailed in Figure 2, isolated semiconductor components typically isolate the power and control circuits in a traction inverter. Three isolated amplifiers or modulators measure motor currents through a shunt resistor and feed the signals to an MCU’s algorithm for field-oriented control (FOC). The need to increase motor speeds requires a higher-bandwidth current-sensing feedback loop, which means that the in-phase current must generate a modified inverter output as quickly as possible. The latency of the current-sensing feedback loop is a priority, especially because power transistor switching frequencies (the insulated gate bipolar transistors [IGBTs]/SiC MOSFETs in Figure 1) are increasing to tens of kilohertz, and control signals must change the pulse width, cycle by cycle, in order to enable a high rotational speed. Noise generated by high currents also affects loop reliability.

Given that the isolated amplifiers are positioned right next to the source of noise, it is important that they operate reliably, with minimal noise interference between the power and control circuits. This is why galvanically isolated amplifiers that offer high transient noise immunity between the power ground and signal ground are necessary in the current-sensing loop. With proper component selection, an accurate current-sensing loop can limit the harmonic distortion of the three current phases to support smooth motor speed and torque control during acceleration and braking conditions. The accuracy of the current-sensing loop also helps prevent electrical losses and minimizes vibrations while driving. Isolated amplifiers such as the AMC1300B-Q1 and AMC1311B-Q1 and isolated modulators such as the AMC1306M25 and AMC1336 support accurate current and voltage measurements with over 200 kHz of bandwidth along with latency of less than 2 µs and galvanic isolation with common-mode transient immunity (CMTI) over 100 kV/µs.

The MCU must take the given three-phase current measurements through an analog-to-digital converter (ADC) to quickly digitize the measurements and feed through the main algorithm to generate pulse-width modulation (PWM) for the traction inverter’s output. The FOC algorithm often used in motor-control designs requires complex math, such as fast Fourier transform (FFT) and trigonometric operations. This leads to high processing bandwidth requirements, especially for switching frequencies of 20 kHz and more.

It is important to distribute the power loads of the MCU so that it can handle both the motor control and safety functions for the traction inverter. A high-speed FOC implementation enables more headroom to the power and processing capability within the MCU to process both motor control and functional safety features. Real-time MCUs such as the C2000™ TMS320F28377D, TMS320F28386D, TMS320F280039C and Sitara™ AM2634-Q1 effectively provide fast control-loop performance, with help from a >3-MSPS ADC for sensing and processing power from multiple optimized cores to perform complex control math quickly. Tightly integrated high-resolution PWMs for actuation help generate precise duty cycles for optimized motor control. When optimized for traction inverters, these stages (ADC input, FOC algorithm execution and PWM write) combine to achieve <4-µs control-loop latency.

How gate drivers and bias supplies can support increased EV ranges

The control signals generated by the MCU and the current-sensing loop are fed to the power stage, which is the link between the battery and the motor. The power stage comprises a high-voltage DC bus decoupled by a large capacitor bank tied to three phases of power transistors, such as IGBTs or SiC MOSFETs. The power stage should have minimal power losses when translating the DC voltage to AC and be small in size in order to use the battery efficiently, which increase a vehicle’s driving range. This is a challenge, however, since components with increased voltage and power are naturally larger. Fortunately, technological breakthroughs have made it possible to keep the same component size for higher power levels.

Two factors influence traction inverter size: the type of high-voltage transistor and the voltage level of the battery. SiC MOSFETs have lower switching losses and a smaller die size when compared to IGBTs with the same voltage rating, which is why some engineers are using SiC MOSFETs in their traction inverter designs. When SiC transistors are controlled properly, they operate with fewer losses and higher reliability across all conditions in which the inverter operates, such as temperature, speed and torque, to enable increased driving ranges.

While SiC MOSFETs are more efficient, like any transistor they will experience some power loss when switching, and those switching losses can impact the efficiency of the traction inverter. The edges of voltage and current during the switching transients overlap and generate power losses, as shown in Figure 3. A high gate-driver output current results in the fast charge and discharge of the SiC FET gate to enable low power loss. It is not always the best idea to switch as fast as possible, however, given variations in switch behavior over temperature, current and voltage. The fast transitions of voltage across a SiC FET, namely the transient voltages (dv/dt) of the drain-to-source voltage (VDS), generate voltage overshoot and electromagnetic interference (EMI) in the form of conducted ground currents. The motor itself can suffer from high dv/dt given the potential for short circuits in the capacitance between the windings. Gate-driver circuitry can control both power losses and switching transients.

Using gate resistance to control the gate driver’s output source and sink current helps optimize the trade-off between dv/dt and power losses. Figure 4 shows an implementation of a gate driver with an adjustable output drive strength to optimize for changes in SiC MOSFET slew rates across temperature and current.

Adjustability is beneficial to traction inverter performance because it enables lower EMI and lower losses, resulting in higher efficiency that helps increase driving ranges. Because TI’s UCC5870-Q1 and UCC5871-Q1 gate drivers have 30-A drive strength, it is very easy to implement an adjustable gate-drive solution based on changing and optimizing the gate resistance. In addition, their galvanic isolation and 100-kV/µs CMTI enable ease of use in high-voltage applications using fast-switching SiC technologies.

The voltage level of the battery also influences the amount of dv/dt present in the system, and creates challenges when designers need to minimize EMI and choose components that can meet isolation safety standards while maintaining the same power density and area. SiC MOSFETs support high breakdown voltages >1,200 V in small die sizes, which enables a power-dense solution for 800-V EV battery applications.

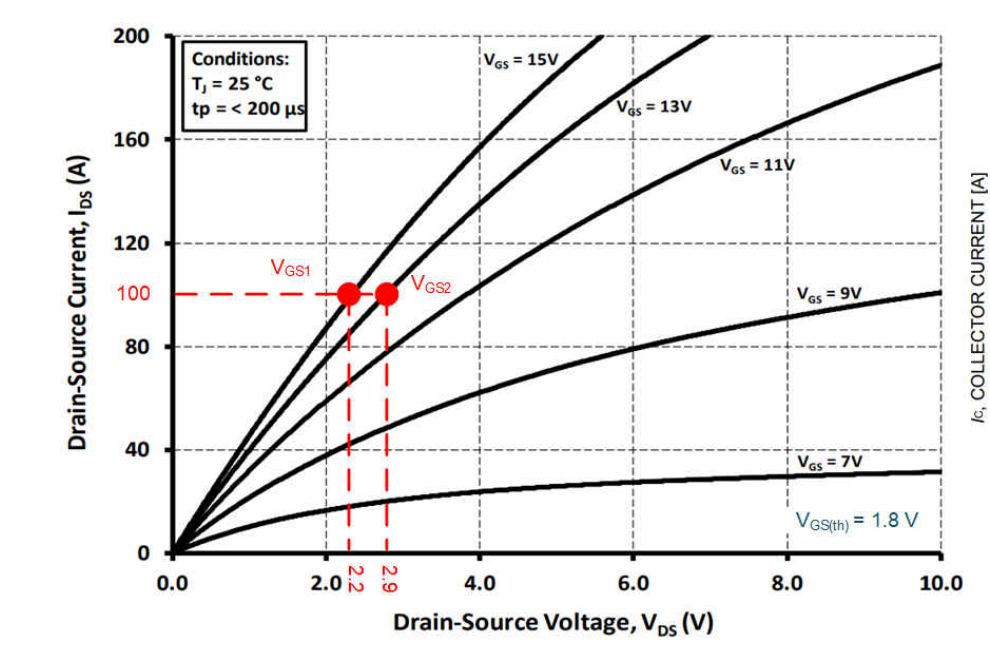

Supporting the gate voltage requirements for high-voltage SiC MOSFETs becomes challenging when the power supply needs isolation and good regulation. The impact of the gate voltage is evident from the current-voltage characteristic curve of a SiC MOSFET, shown in Figure 5, where a higher gate-to-source voltage (VGS) results in a steeper curve in its linear region. A steeper curve means a lower drain-to-source on-resistance (RDS(on)) to minimize conduction losses and avoid thermal runaway.

Figure 5 SiC MOSFET voltage and current

characteristics based on the VGS.

Figure 5 SiC MOSFET voltage and current

characteristics based on the VGS.The isolated bias supply that provides power and voltage to the gate driver should maintain a proper positive gate voltage during fast transients and be able to support negative voltages to keep the SiC FET safely off. Transformers with semiconductor switching controllers are often used to generate isolated power supplies. Their complex design, however, directly impacts the performance of the power stage from both the electrical efficiency and EMI perspectives. The interwinding capacitance results in higher common-mode currents that lead to the generation of EMI where lower capacitance is necessary, but trade-offs between size, voltage ratings and efficiency require more time to design.

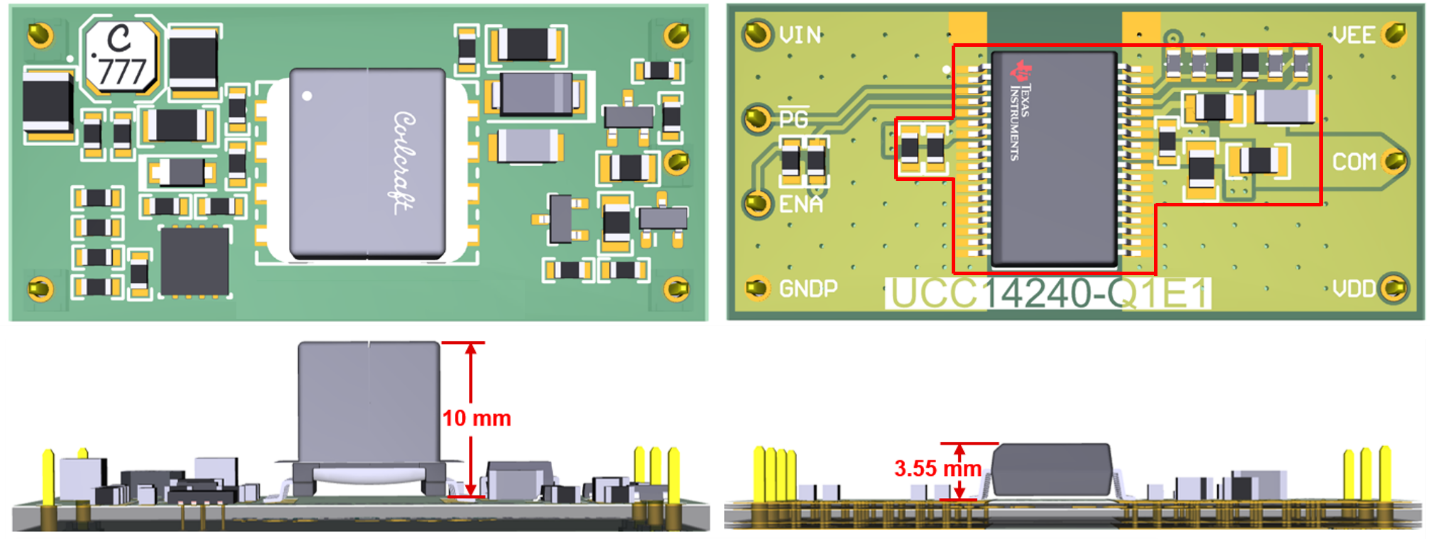

With integrated power modules such as the UCC14241-Q1 and UCC1420-Q1, the primary-to-secondary isolated capacitance can be well controlled at <3.5 pF, enabling a CMTI of >150 V/ns for fast-switching SiC MOSFETs. HEV/EV subsystem design is trending toward further integration, such as combining the traction inverter with a DC/DC converter. The UCC14241-Q1 can achieve an approximately 40% smaller bill-of-materials (BOM) area than a typical bias supply solution with a flyback converter, as shown in Figure 6. The height compared to the discrete transformer design is substantially lower, leading to a lower center of gravity and a higher vibration tolerance. All of these factors contribute to the reliability and longevity of traction inverter systems, while providing the correct voltages to efficiently drive the power transistors.

Figure 6 BOM area and height comparison

between typical a flyback converter bias solution and the UCC14240-Q1.

Figure 6 BOM area and height comparison

between typical a flyback converter bias solution and the UCC14240-Q1.