-

TurboTrans™ Technology: One Resistor Dramatically Improves Transient Performance and Reduces Solution Size

TurboTrans™ Technology: One Resistor Dramatically Improves Transient Performance and Reduces Solution Size

Ever-evolving technology demands smaller, modular, performance-driven solutions. Power modules contribute to small solution sizes and board-space requirements, but can reduce design flexibility. While power modules reduce solution sizes, there's been an additional push to improve transient response. Many newer DC/DC regulators and power modules internalize loop compensation or feature operating architectures that do not require loop compensation, making them very easy to use. But in some cases, that could reduce your ability to fine-tune design performance.

Solving the Problem of Fast Transient Response with Accuracy

As process technology advances, processors require tighter voltage accuracy and lower core voltages. Table 1 is a chart from a field-programmable gate array (FPGA) datasheet stating that the recommended operating conditions for the VCCINT rail are 1V, plus and minus 30mV. It is recommend to stay within this 3% range because the processor could behave unexpectedly outside this voltage window. Thus, you may have to increase the capacitance at the output of DC/DC converters to meet the 3% range during load changes.

| Symbol | Min | Typ | Max | Units |

|---|---|---|---|---|

| FPGA logic | ||||

| VCCINT | 0.97 | 1.00 | 1.03 | V |

| 0.87 | 0.90 | 0.93 | V | |

| VCCBRAM | 0.97 | 1.00 | 1.03 | V |

| 0.87 | 0.90 | 1.03 | V | |

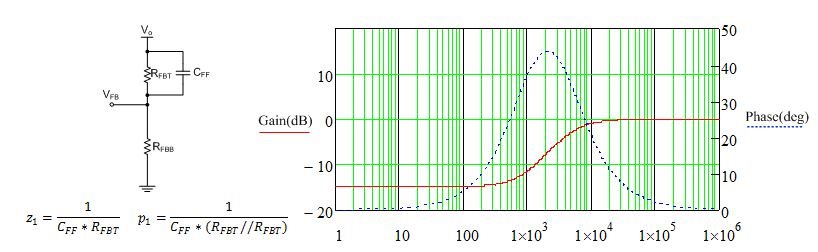

While small capacitance increments are allowable, larger amounts could negatively affect the module’s load transient response. To optimize transient response, designers typically add a feedforward capacitor (CFF) in parallel with the upper feedback resistor, as shown in Figure 1. In the frequency domain the addition of CFF creates a zero, which increases bandwidth and improves the transient response time.

Figure 1 Feedback Divider with

Feedforward Capacitor CFF

Figure 1 Feedback Divider with

Feedforward Capacitor CFFUnfortunately, this solution isn't perfect either; while CFF creates a zero to help increase bandwidth, it also creates a subsequent pole as a product of CFF and the parallel combination of feedback resistors. This pole can negate the benefits brought about by the zero of the CFF. Since CFF adds a zero and a pole, which may not be too far apart in frequency, the choice and calculation of CFF becomes tricky. The right CFF value will help the situation, while a wrong CFF value will bring no improvement and will just be a useless addition to the bill of materials (BOM).

How One Resistor Can Improve Performance

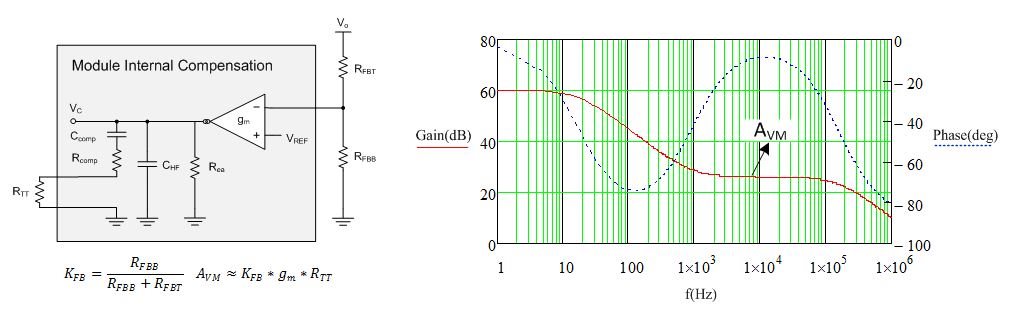

TurboTrans™ technology, shown in Figure 2, improves the loop response by adding just one resistor (RTT). Adding an RTT resistor enables you to optimize the feedback loop easily using a resistor outside of the module. By adjusting the TurboTrans resistor, you can optimize the zero and midband gain (AVM) of the compensation stage as required. There are no side effects like that of a consequent CFF pole with the use of a RTT resistor.

Figure 2 Power Module with TurboTrans

Technology

Figure 2 Power Module with TurboTrans

TechnologyThe RTT resistor is nothing but an additional series resistor in the Type II compensation scheme. This additional RTT resistor doesn’t require in-depth knowledge of loop compensation techniques because, like for any other power module, the data sheet will provide an equation to calculate the right value. Your calculation will simply depend on the amount of total output capacitance. The RTT will compensate for any additional capacitance at the output, and the load transient response will remain spectacular.

TurboTrans in Action

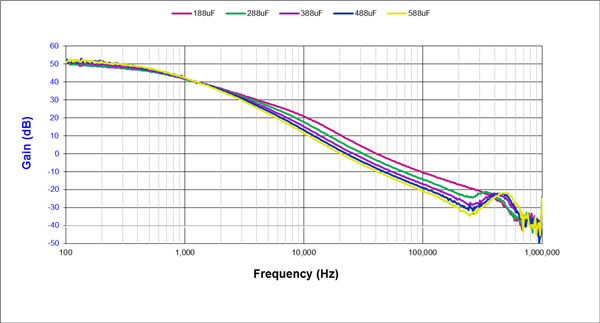

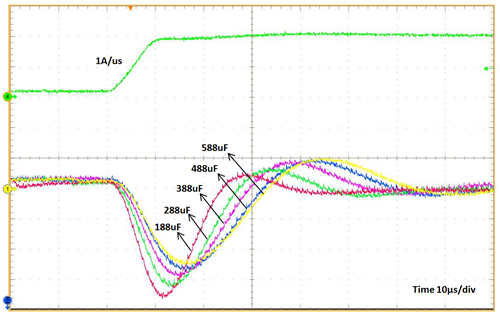

Let’s use TI’s TPSM84824 to show how TurboTrans technology helps achieve a fast transient response. In order to meet the 3% range (recalling Table 1), the only thing you can do in the absence of TurboTrans technology is increase the output capacitance. As you can see in Figure 4 and Table 2, capacitance increments have little effect on the voltage droop. That’s because with increasing output capacitance, the overall bandwidth of the regulator reduces considerably (as shown in Figure 3). This makes the loop slow and increases the time required to react to a load transient. Consequently, even with a large value of output capacitance, the power module still cannot maintain less than 30mV of voltage droop.

Figure 3 Gain Curve with Different

Output Capacitance

Figure 3 Gain Curve with Different

Output Capacitance Figure 4 Transient Response with

Different Output Capacitance

Figure 4 Transient Response with

Different Output Capacitance| Output capacitance (µF) | Crossover frequency (kHz) | Voltage droop (mV) |

|---|---|---|

| 188 | 41.0 | 114.6 |

| 288 | 31.3 | 103.2 |

| 388 | 26.0 | 92.4 |

| 488 | 22.8 | 86.4 |

| 588 | 20.5 | 82.2 |

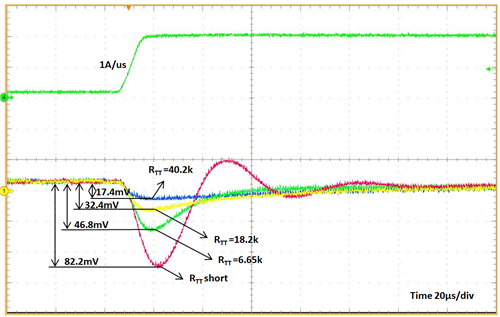

The situation improves if you use the TurboTrans feature. By adjusting the TurboTrans resistor, you can easily get 17.4mV of voltage droop, as shown in Figure 5.

Figure 5 Transient Response with

TurboTrans Technology

Figure 5 Transient Response with

TurboTrans TechnologyConclusion

As the experimental results show, TurboTrans technology enables you to considerably improve the performance of your power module while potentially reducing the overall capacitance at the output. This not only boosts the performance of the applications, but also leads to reduced system cost and size.

Additional Resources

- Learn more about TI DC/DC power modules.

- Read the application report, “LMZ1050x/LMZ1050xEXT SIMPLE SWITCHER® Power Module – Quick Compensation Design.”

IMPORTANT NOTICE AND DISCLAIMER

TI PROVIDES TECHNICAL AND RELIABILITY DATA (INCLUDING DATASHEETS), DESIGN RESOURCES (INCLUDING REFERENCE DESIGNS), APPLICATION OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND OTHER RESOURCES “AS IS” AND WITH ALL FAULTS, AND DISCLAIMS ALL WARRANTIES, EXPRESS AND IMPLIED, INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT OF THIRD PARTY INTELLECTUAL PROPERTY RIGHTS.

These resources are intended for skilled developers designing with TI products. You are solely responsible for (1) selecting the appropriate TI products for your application, (2) designing, validating and testing your application, and (3) ensuring your application meets applicable standards, and any other safety, security, or other requirements. These resources are subject to change without notice. TI grants you permission to use these resources only for development of an application that uses the TI products described in the resource. Other reproduction and display of these resources is prohibited. No license is granted to any other TI intellectual property right or to any third party intellectual property right. TI disclaims responsibility for, and you will fully indemnify TI and its representatives against, any claims, damages, costs, losses, and liabilities arising out of your use of these resources.

TI’s products are provided subject to TI’s Terms of Sale (www.ti.com/legal/termsofsale.html) or other applicable terms available either on ti.com or provided in conjunction with such TI products. TI’s provision of these resources does not expand or otherwise alter TI’s applicable warranties or warranty disclaimers for TI products.

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2023, Texas Instruments Incorporated