-

How to Avoid Motor and System Overvoltage Using AVS Technology without External Components

How to Avoid Motor and System Overvoltage Using AVS Technology without External Components

Innocent Irakoze

In the world of advanced and complex technology, system protection becomes a very important aspect of delivering reliable, robust and high-performance equipments for both industrial and automotive that’s protected against malfunctioning due to overvoltage or overcurrent.

For motor-based systems, there must be an energy transferred to the motor in order for the motor to spin. The energy transmitted from a power supply to the motor generates angular motions that under some uncertain conditions might return that energy back to the power supply. This returned energy can aggravate system overvoltage to cause device failures and even sometimes destroy motor-drive stages. These failures are due to a condition called voltage surge.

Let’s examine which conditions cause these device failures. For systems requiring a motor, two types of energies facilitate system operation: inductive energy and mechanical energy.

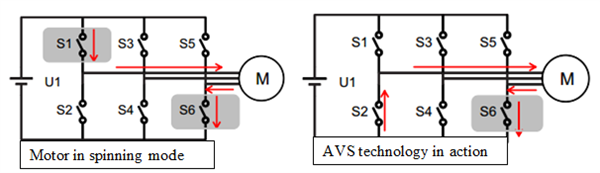

Inductive energy occurs when the current flowing in the inductance of a motor continues to flow through the intrinsic body diode of the MOSFET, which eventually causes an increase in the supply voltage. Figure 1 shows what happens when an inductive energy is active.

Figure 1 Inductive Mode Voltage

Surge

Figure 1 Inductive Mode Voltage

SurgeYou can see in Figure 1 on the left that current is flowing from S1, then S6, which makes the inductive energy return to ground. On the right, in active tri-state mode, if the current flows from S2, then to S5, and the inductive energy is dumped in the supply voltage (VCC).

To prevent this generated inductive energy from returning to the power supply, TI integrated circuits (ICs) come with Anti-Voltage Surge (AVS) technology to monitor both high- and low-side current. See Figure 2.

Figure 2 Inductive AVS

Implemented

Figure 2 Inductive AVS

ImplementedMechanical energy is caused by an unexpected decrease in speed, which might cause the supply voltage to drop lower than the back electromagnetive force (BEMF) voltage. In this scenario, the motor works as a generator and current flows back to the power supply.

AVS prevents these conditions from occurring, thus preventing energy from being transferred from the motor back to the power supply. AVS also protects other devices connected directly to the power supply. This is significant, because it enables you to remove devices designed to protect against overvoltage. The elimination of these extra protection components helps simply the design, minimizes board space and improves system performance. In addition, it saves design time and reduce overall system cost.

AVS monitors speed commands and limits the value of the supplied voltage from exceeding the motor’s BEMF. Upon the detection of a voltage surge, AVS quickly reacts to maintain the desired output amplitude during system operation.

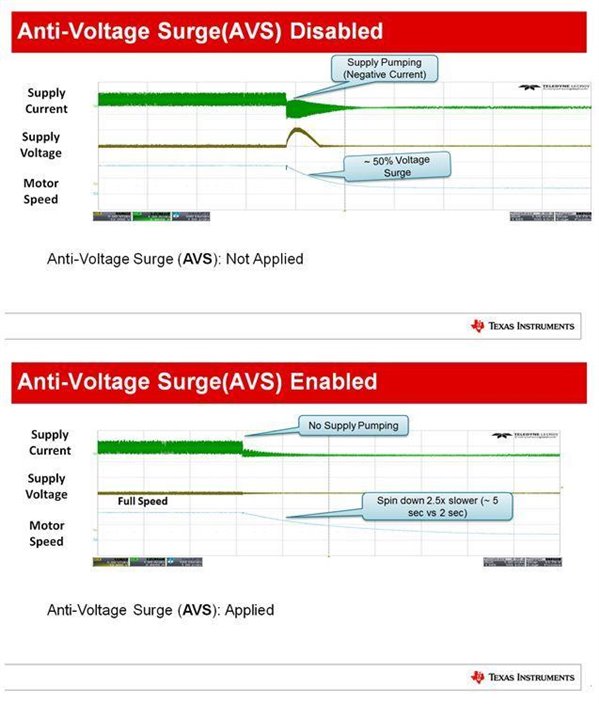

AVS is available in many Texas Instruments motor driver ICs, including the DRV10983, DRV10975, DRV10963 and DRV10964. Figure 3 shows the spin of the DRV10983 motor driver with AVS both enabled and disabled.

Figure 3 AVS Wavefroms (AVS Applied vs

AVS Not Applied )

Figure 3 AVS Wavefroms (AVS Applied vs

AVS Not Applied )Design protection is very important in today’s complex technology world. AVS, a technology developed from Texas Instruments, monitors and prevents unwanted conditions to the system. These conditions can cause overvoltage, failure and sometimes destroy the system. A motor-based design is simplified, made more robust and reliable by designing and utilizing products that support AVS technology to help prevent overvoltage from occurring. What is your experience designing with brushless DC motors? Sign in and comment below.

Additional Resources

- Learn more about Brushless DC (BLDC) drivers.

- Visit the TI E2E™ Community Motor Drivers forum.

IMPORTANT NOTICE AND DISCLAIMER

TI PROVIDES TECHNICAL AND RELIABILITY DATA (INCLUDING DATASHEETS), DESIGN RESOURCES (INCLUDING REFERENCE DESIGNS), APPLICATION OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND OTHER RESOURCES “AS IS” AND WITH ALL FAULTS, AND DISCLAIMS ALL WARRANTIES, EXPRESS AND IMPLIED, INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT OF THIRD PARTY INTELLECTUAL PROPERTY RIGHTS.

These resources are intended for skilled developers designing with TI products. You are solely responsible for (1) selecting the appropriate TI products for your application, (2) designing, validating and testing your application, and (3) ensuring your application meets applicable standards, and any other safety, security, or other requirements. These resources are subject to change without notice. TI grants you permission to use these resources only for development of an application that uses the TI products described in the resource. Other reproduction and display of these resources is prohibited. No license is granted to any other TI intellectual property right or to any third party intellectual property right. TI disclaims responsibility for, and you will fully indemnify TI and its representatives against, any claims, damages, costs, losses, and liabilities arising out of your use of these resources.

TI’s products are provided subject to TI’s Terms of Sale (www.ti.com/legal/termsofsale.html) or other applicable terms available either on ti.com or provided in conjunction with such TI products. TI’s provision of these resources does not expand or otherwise alter TI’s applicable warranties or warranty disclaimers for TI products.

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2023, Texas Instruments Incorporated