-

Understanding Isolator Failure Modes for Safe Isolation

Understanding Isolator Failure Modes for Safe Isolation

Anant Kamath

In my earlier blog posts on isolation, I’ve mentioned one of the key applications of isolation: protection against electrical shock.

In high-voltage applications, a failure of the isolation barrier can result in a potential operator safety hazard or cause damage to sensitive control circuitry, leading to system malfunction. Therefore, it is important to understand what may cause the isolator to fail, both under normal and fault conditions. You need to know the nature of the failure in each case to know if you need to put additional measures in place to prevent an electrical hazard.

So what causes an isolator to fail?

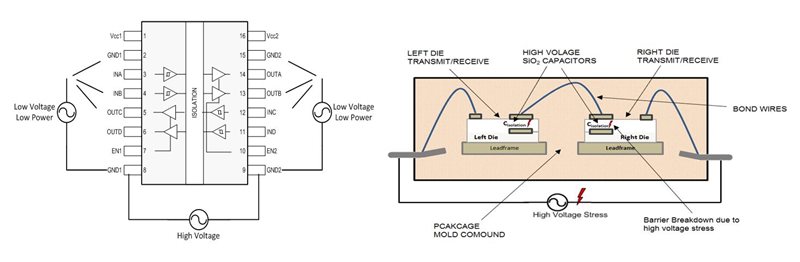

The first failure mode (failure mode 1) is when a high voltage exceeding the isolator’s rated specifications occurs across the isolation barrier, resulting in insulation breakdown. This high voltage could be in the form of a sinusoidal voltage lasting a few seconds or minutes, a surge impulse due to direct and indirect lightning strikes, or a continuous overvoltage lasting months or years. Figure 1 shows this failure mode.

Failure mode 1 occurs in all isolators and couplers, magnetic, capacitive and optical, irrespective of type and construction. It is easy to avoid in the final system: just choose an isolator whose rated specifications exceed the voltages expected in the end equipment under all conditions. End-equipment standards (such as International Electrotechnical Commission (IEC) 61800-5-1 for adjustable speed motor drives) make this choice simple by establishing clear guidelines to ensure electrical safety. TI’s reinforced isolators provide one of the highest isolation ratings in the industry, and hence crucial margin against failure mode 1 in several applications.

Figure 1 Failure Mode 1 Is a High

Voltage across the Isolation Barrier

Figure 1 Failure Mode 1 Is a High

Voltage across the Isolation BarrierThe second failure mode, failure mode 2, occurs when a high-power event, defined as a combination of a high voltage and high-current events, occurs on one of the sides of the isolator. The excessive heat and mechanical stress caused by such an event can destroy the associated silicon die. The insulation in TI’s reinforced isolators is made of a series combination of two high-voltage capacitors placed on two different silicon dies. Even if one die is damaged due to electrical overstress, the other die remains intact, providing basic isolation. This characteristic is called “fail open” behavior. Failure mode 2 is shown in Figure 2.

Figure 2 Failure Mode 2 Is High Voltage

and High Current Close to an Isolation Barrier

Figure 2 Failure Mode 2 Is High Voltage

and High Current Close to an Isolation BarrierFigure 3 shows photographs of a decapsulated TI-reinforced isolator showing one half of the isolation intact, even after being subject to surge voltage on one of the two sides. Many competition isolation solutions do not use two separate isolation barriers in series, and hence can be “fail short” in similar situations, compromising electrical safety.

Figure 3 TI-reinforced Isolators

Survive Failure Mode 2

Figure 3 TI-reinforced Isolators

Survive Failure Mode 2In our white paper, “Understanding failure modes in isolators,” Neeraj Bharadwaj, Kannan Soundarapandian and I discuss this topic in detail. In this white paper, we also show several experimental results that demonstrate the fail open behavior of TI-reinforced isolators.

How is isolation making your system safer? Log in to post a comment below.

Additional Resources

- Read the data sheets for TI’s ISO5851 and ISO5852S isolated gate drivers, AMC1305 isolated delta-sigma modulators and ISO78xx digital isolators. Download the whitepaper “Isolation in AC Motor Drives: Understanding the IEC 61800-5-1 Safety Standard”.

- See TI’s entire isolation portfolio.

IMPORTANT NOTICE AND DISCLAIMER

TI PROVIDES TECHNICAL AND RELIABILITY DATA (INCLUDING DATASHEETS), DESIGN RESOURCES (INCLUDING REFERENCE DESIGNS), APPLICATION OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND OTHER RESOURCES “AS IS” AND WITH ALL FAULTS, AND DISCLAIMS ALL WARRANTIES, EXPRESS AND IMPLIED, INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT OF THIRD PARTY INTELLECTUAL PROPERTY RIGHTS.

These resources are intended for skilled developers designing with TI products. You are solely responsible for (1) selecting the appropriate TI products for your application, (2) designing, validating and testing your application, and (3) ensuring your application meets applicable standards, and any other safety, security, or other requirements. These resources are subject to change without notice. TI grants you permission to use these resources only for development of an application that uses the TI products described in the resource. Other reproduction and display of these resources is prohibited. No license is granted to any other TI intellectual property right or to any third party intellectual property right. TI disclaims responsibility for, and you will fully indemnify TI and its representatives against, any claims, damages, costs, losses, and liabilities arising out of your use of these resources.

TI’s products are provided subject to TI’s Terms of Sale (www.ti.com/legal/termsofsale.html) or other applicable terms available either on ti.com or provided in conjunction with such TI products. TI’s provision of these resources does not expand or otherwise alter TI’s applicable warranties or warranty disclaimers for TI products.

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2023, Texas Instruments Incorporated