-

Top 3 ways to reduce audible noise in motion control applications

Top 3 ways to reduce audible noise in motion control applications

Robert Wedan

With the emergence of open-concept floor plans for homes and offices and the shift to hybrid electric vehicles and electric vehicles, demand for quieter and more efficient motor control is increasing significantly. Even the smallest differences in acoustics can make a big difference in audible noise.

In Figure 1, you can see how appliances in a living space contribute to overall noise levels. Advanced real-time control techniques can help you achieve better acoustic performance for your systems, including motor control circuitry with higher power density, more integration, and more efficient systems. Some additional strategies include vector field-oriented control (FOC) algorithms using continuous pulse-width modulation (PWM), specific control algorithms to reduce vibrations, and integrated control to apply dead-time compensation and PWM generation to reduce audible noise.

Figure 1 Audible noise in an open

concept kitchen and living room

Figure 1 Audible noise in an open

concept kitchen and living roomWith all of these different products and strategies to reduce audible noise in motion control applications, it may be difficult to know which strategy is best for your application. In this article, I’ll list the top three ways to reduce audible noise in motion control applications, using BLDC integrated control gate drivers as examples.

PWM

The first strategy in reducing audible noise in motion control applications is continuous PWM. PWM is a technique that generates output waveforms by turning transistors on and off, resulting in the motor voltage being high or low at any given time. The inductance in the motor then filters these waveforms to essentially average the output waveform. Adjusting the duty cycle (the ratio of the time the waveform is on compared to the time it is off) will change the average voltage. Figure 2 illustrates an example of sinewave generation using PWM.

Figure 2 Example sinewave generation

using PWM

Figure 2 Example sinewave generation

using PWMFor example, TI’s MCF8315A BLDC integrated control gate driver, a sensorless FOC motor driver, implements continuous and discontinuous space-vector PWM schemes. Continuous modulation helps reduce current ripple for motors with low inductance, but results in higher switching losses because all three phases are switching. Discontinuous modulation has lower switching losses (because there are only two phases switching at a time) but higher current ripple. In Figure 3 and Figure 4, you can see the differences between continuous and discontinuous PWM.

Figure 3 Phase-current waveform and

fast Fourier transform (FFT) discontinuous PWM

Figure 3 Phase-current waveform and

fast Fourier transform (FFT) discontinuous PWM Figure 4 Phase-current waveform and FFT

continuous PWM

Figure 4 Phase-current waveform and FFT

continuous PWMDead-time compensation

The second strategy used to reduce audible noise in motion control applications is dead-time compensation. In motor control applications, inserting dead time between the switching of the high- and low-side metal-oxide semiconductor field-effect transistors in a half bridge can avoid a shoot-through condition. After inserting dead time, the expected voltage and applied voltage at the phase node will differ, and the phase-node voltage introduces unwanted distortion in the phase current, causing audible noise.

To manage this additional noise, engineers can integrate dead-time compensation using a resonant controller to control the harmonic component in the phase current, alleviating the current distortion caused by the dead time, as shown in Figure 5.

Figure 5 Sensorless FOC dead-time

compensation analysis

Figure 5 Sensorless FOC dead-time

compensation analysisFor example, TI’s MCF8316A BLDC integrated control gate driver, a sensorless FOC motor driver, uses this built in feature to optimize acoustics across multiple electrical speeds as shown in Figure 6.

Figure 6 PWM modulation and dead-time

compensation implemented to optimize MCF8316A acoustics

Figure 6 PWM modulation and dead-time

compensation implemented to optimize MCF8316A acousticsVariable commutation modes

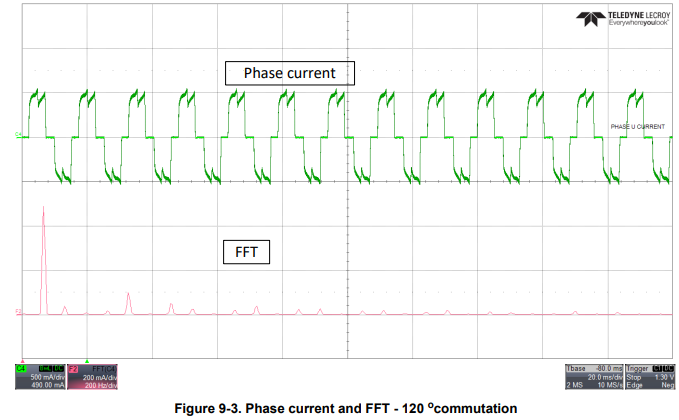

The last technique for reducing audible noise in motion control applications is variable commutation modes. In trapezoidal commutation, there are two main configurations: 120 degrees and 150 degrees. Trapezoidal 120 degrees may result in more acoustic noise because the long high-impedance period causes increased torque ripple; see Figure 7 and Figure 8. And trapezoidal 150 degrees can only operate at low speeds, given the small window for detecting the zero crossing.

To combat these challenges and improve acoustic performance, engineers can build motor driver systems that can dynamically switch between trapezoidal 120 degrees and trapezoidal 150 degrees. This dynamic modulation can improve overall acoustic performance during BLDC motor control.

Figure 7 Phase current and FFT – 120-degree commutation

Figure 7 Phase current and FFT – 120-degree commutation Figure 8 Phase current and FFT – 150-degree commutation

Figure 8 Phase current and FFT – 150-degree commutationFor example, TI’s sensorless BLDC integrated trapezoidal control gate drivers, like MCT8329 and MCT8316, use this built in feature to optimize acoustics across multiple electrical speeds as shown in Figure 9.

Figure 9 Variable commutation modes

with dynamic modulation implemented to optimize MCT8316A acoustics

Figure 9 Variable commutation modes

with dynamic modulation implemented to optimize MCT8316A acousticsConclusion

TI is investing in motion control technologies to help build more efficient and acoustic-sensitive systems, with building blocks designed to meet acoustic requirements. When designing your system, keep in mind these top three ways to reduce audible noise in motion control applications.

Additional resources

- Check out the application report on “How to Reduce Motor Noise with Code-Free, Sensorless BLDC Motor Drivers” or the video, “Reduce audible motor noise with BLDC motor drivers.”

- Learn more about TI’s integrated control BLDC drivers, BLDC motor drivers, Arm®-based processors, C2000™ real-time microcontrollers and MSP430™ microcontrollers.

- Read the application brief, "High-Efficiency , Code-Free Sensorless BLDC Motor Drives for Scalable Systems."

IMPORTANT NOTICE AND DISCLAIMER

TI PROVIDES TECHNICAL AND RELIABILITY DATA (INCLUDING DATASHEETS), DESIGN RESOURCES (INCLUDING REFERENCE DESIGNS), APPLICATION OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND OTHER RESOURCES “AS IS” AND WITH ALL FAULTS, AND DISCLAIMS ALL WARRANTIES, EXPRESS AND IMPLIED, INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT OF THIRD PARTY INTELLECTUAL PROPERTY RIGHTS.

These resources are intended for skilled developers designing with TI products. You are solely responsible for (1) selecting the appropriate TI products for your application, (2) designing, validating and testing your application, and (3) ensuring your application meets applicable standards, and any other safety, security, or other requirements. These resources are subject to change without notice. TI grants you permission to use these resources only for development of an application that uses the TI products described in the resource. Other reproduction and display of these resources is prohibited. No license is granted to any other TI intellectual property right or to any third party intellectual property right. TI disclaims responsibility for, and you will fully indemnify TI and its representatives against, any claims, damages, costs, losses, and liabilities arising out of your use of these resources.

TI’s products are provided subject to TI’s Terms of Sale (www.ti.com/legal/termsofsale.html) or other applicable terms available either on ti.com or provided in conjunction with such TI products. TI’s provision of these resources does not expand or otherwise alter TI’s applicable warranties or warranty disclaimers for TI products.

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2023, Texas Instruments Incorporated