-

Why use PSR-flyback isolated converters in dual-battery mHEV systems SLYT791A may 2020 – may 2020 LM25180 , LM25180-Q1 , LM25183 , LM25183-Q1 , LM25184 , LM25184-Q1 , LM5170-Q1 , LM5180 , LM5180-Q1 , LM5181 , LM5181-Q1 , UCC20225A-Q1

-

Why use PSR-flyback isolated converters in dual-battery mHEV systems

Why use PSR-flyback isolated converters in dual-battery mHEV systems

1 Introduction

With the growing power demands of automotive systems, the increasingly strict government mandates for green-house gas emissions, and the conversion from mechanical components to electrical functions for reduced size and weight, the traditional 12-V automotive lead-acid battery has reached its usable power limit.[1, 2] To address this power limitation, automakers are developing a dual-voltage electrical platform that combines a smaller 12-V battery (for compatibility with existing systems) with a 48-V lithiumion battery pack that runs high power loads that includes:

- Powertrain—electric supercharging and regenerative braking.

- Chassis/safety—active roll stabilization and automated driving systems such as radar, camera, LIDAR and ultrasonic sensor systems.

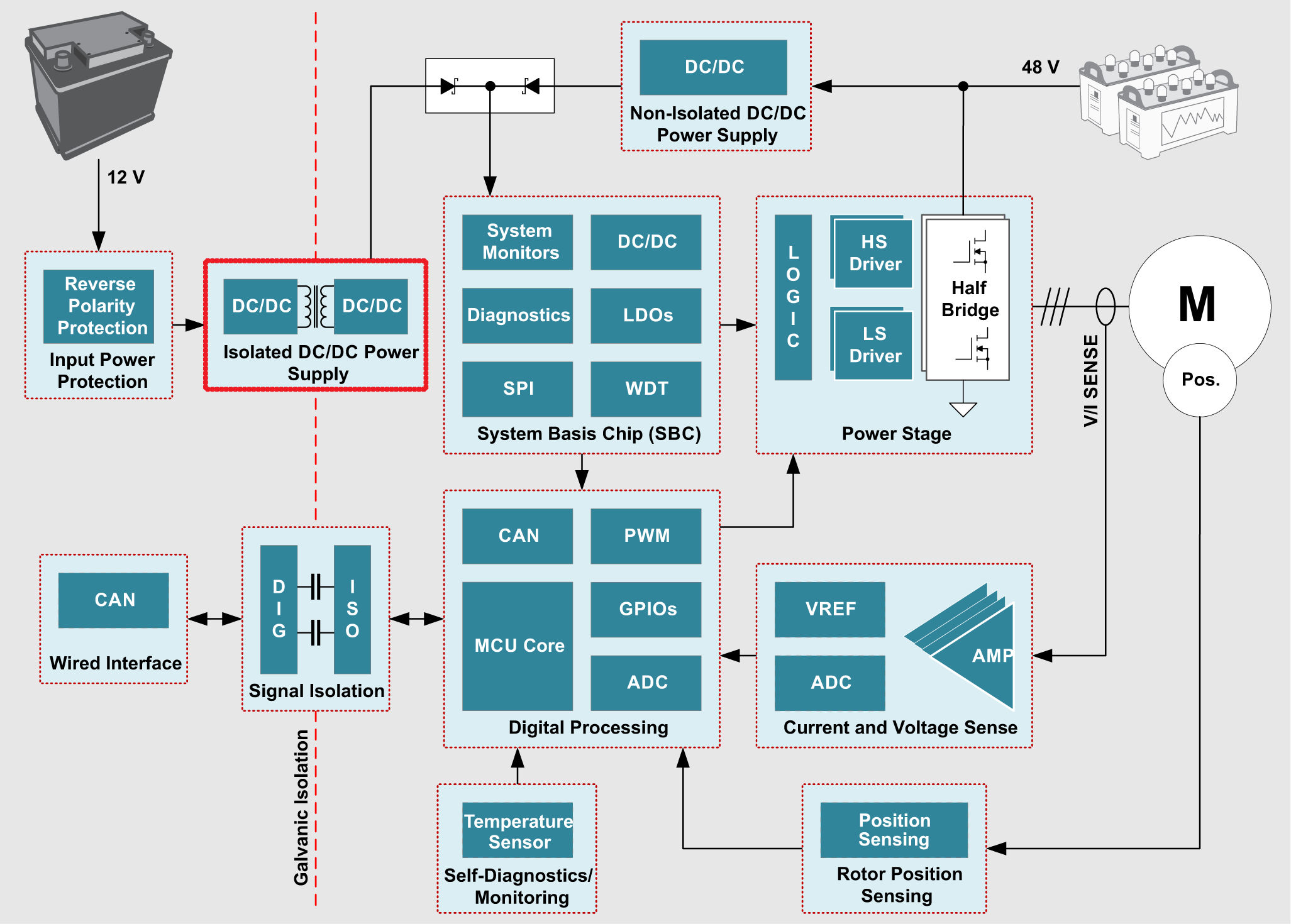

This dual-bus architecture, as presented in Figure 1, provides a pathway to improve the performance of conventional internal combustion engine (ICE) gasoline or diesel vehicles with less of the cost-weight penalty incurred by installing a full hybrid drivetrain.[3, 4] This mild-hybrid electric vehicle (mHEV) architecture involves a relatively unobtrusive electrification of the powertrain. Also, with steady-state voltages less than 60 V, the system is not designated as “high voltage.”

As a result, an mHEV system requires:

- Much less effort in terms of insulation protection.

- Electrical components that are smaller and have a lower incremental cost.

- A more compact design, given the lower clearance spacing between individual components compared to a solution with high-voltage hybridization.

As depicted in Figure 1, a belt-integrated starter-generator (BiSG) delivers recuperated energy to the 48-V board net (BN48) and battery. This configuration also enables some level of torque assist through belt coupling to the engine’s front-end accessory drive. This is known as a P0 configuration.[5,6 ] Other topologies are designated as P1, P2, P3 or P4, where the electric machine may couple to the crankshaft, transmission or rear axle drive.

A current-controlled buck/boost regulator (plus safety switches)[2, 7] provides bidirectional power transfer capability between the BN12 (12-V) and BN48 (48-V) ports in Figure 1, which enables both batteries to simultaneously supply power if needed. The basic half-bridge switching cell of the regulator is scalable to meet higher current demands by supporting multiple phases connected in parallel. Note that there is a common ground for low- and high-voltage systems, and the ground terminals are attached via physically separate grounding bolts/ connections.[3, 4]

Figure 1 Simplified

Example of a mHEV Dual-battery System

Figure 1 Simplified

Example of a mHEV Dual-battery SystemThis article focuses on the isolated supply that powers the signal path and control circuits on the 48-V side. The primary-side regulated (PSR) flyback converter family as described offers simplicity, versatility, small solution size, low noise, high reliability and low bill-of-materials cost.

2 Functional Isolation in mHEV Systems

Unlike high-voltage HEV systems that require a reinforced grade of isolation for electric shock protection and safety, the power stages in an mHEV are non-isolated, hence lowering overall system and maintenance costs. However, functional-grade isolation of the control circuits in an mHEV system improves robustness by increasing noise immunity, especially given the high slew-rate switched voltages and currents in the inverter/rectifier and DC/DC power stages. Isolation also reduces ground loops between various subsystems and mitigates electrostatic discharge and electric fast transients. Specific areas of concern related to arcing and fusing are also significant. To add some perspective, Figure 2 details the essential subsystems of a starter-generator system.[6,7]

Figure 2 has a red dashed line that indicates the isolation boundary separating the 12-V and 48-V sides. An isolated power source derived from the 12-V battery, typically implemented as a flyback converter, provides redundant and fault-tolerant backup for an auxiliary-bias supply rail on the 48-V side, with a typical output voltage setpoint of 12 V. This auxiliary supply rail, normally derived from the 48-V battery using a buck converter, supplies the system-basis chip that subsequently powers the embedded processing subsystem, as well as various monitoring and sensing circuits. Depending on the state of charge of each battery (for example, after long-term parking), startup considerations, fault management and other factors, the powertrain control unit may enable or disable the flyback converter as needed.

Having isolation is also useful for the vehicle communication network, especially to deal with ground voltage offsets or loss-of-ground faults on either the 12-V or 48-V side.[3] Finally, as power levels of the motor-generator in mHEV systems increase toward 30 kW, the high-side switch gate drivers of the inverter/rectifier stage integrated in the motor-generator also benefit from isolation. An example of an isolated dual-channel gate driver for 48-V applications is the UCC20225A-Q1. The multi-output capability of a flyback converter is useful here, especially if floating or bipolar gate-drive voltages are required.

Figure 2 Block Diagram of a

Starter-generator System (Isolated DC/DC Stage Highlighted in Red)

Figure 2 Block Diagram of a

Starter-generator System (Isolated DC/DC Stage Highlighted in Red)