-

Using isolated comparators for fault detection in electric motor drives

- 1Introduction

- 2Introduction to electric motor drives

- 3Understanding fault events in electric motor drives

- 4Achieving reliable detection and protection in electric motor drives

- 5Use case No. 1: Bidirectional in-phase overcurrent detection

- 6Use case No. 2: DC+ overcurrent detection

- 7Use case No. 3: DC– overcurrent or short-circuit detection

- 8Use case No. 4: DC-link (DC+ to DC–) overvoltage and undervoltage detection

- 9Use case No. 5: IGBT module overtemperature detection

- IMPORTANT NOTICE

Using isolated comparators for fault detection in electric motor drives

1 Introduction

An electric motor drive is an electrical system that provides a variable frequency output to an electric motor to drive industrial loads such as heating and air-conditioning, ventilation, pumps, compressors, and elevators, and factory automation loads such as conveyor belts, mining, and papermill equipment.

Electric motor drives in industrial environments experience conditions such as high temperatures and high humidity, AC power-line fluctuations, and mechanical overloads. Users are demanding greater efficiency, along with more reliability. The switching speeds of power semiconductor devices such as insulated-gate bipolar transistors (IGBTs) are continuously increasing, with greater adoption of wide-bandgap technologies such as silicon carbide (SiC) and gallium nitride (GaN) that enable faster switching speeds. Given the increasing need for higher switching speeds and more system reliability, modern motor-drive systems must both detect and protect against several fault events to minimize industrial equipment downtime.

In this article, I will discuss the priority level and impact of different fault events, along with how to detect them to prevent damage to motor-drive circuits.

2 Introduction to electric motor drives

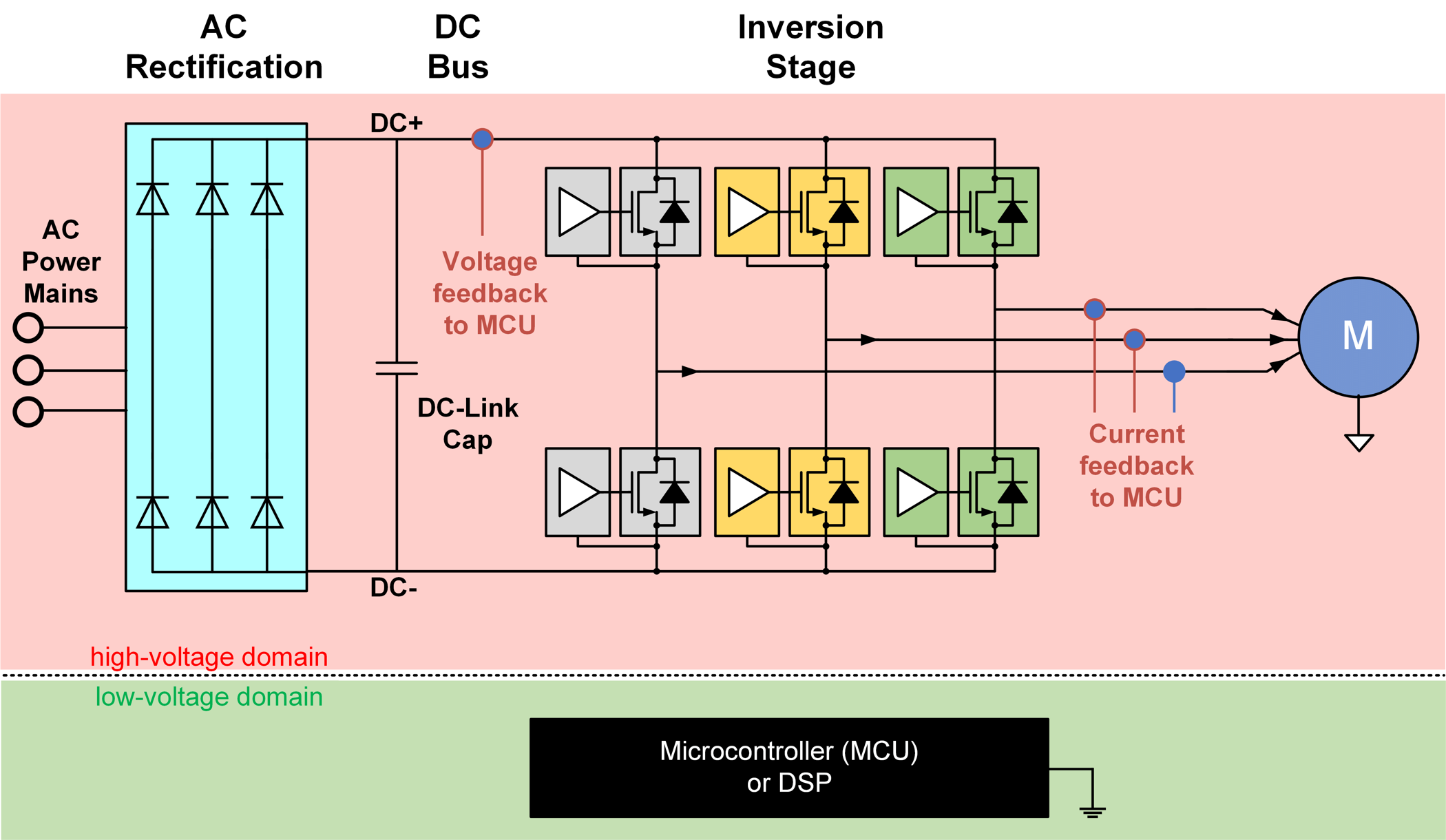

An electric motor-drive system, as shown in Figure 2-1, takes power from the AC mains, rectifies it to a DC voltage, and inverts the DC back to AC with variable magnitude and frequency based on load demand through complex feedback control algorithms.

A motor-drive system typically has two voltage domains: the “high-voltage” domain and the “low-voltage” domain. The microcontroller or digital signal processor, typically on the low-voltage domain, receives feedback signals (voltage, current, temperature, etc.) from the three-phase IGBT power stage and generates pulse-width modulated signals for controlling the power switching transistors and other high-side power circuitry. Such systems demand resilient and reliable galvanic isolation to isolate high-voltage circuits from low-voltage circuits. An isolation architecture enables reliable operation of motor-drive systems, preventing damage to expensive circuitry by breaking the ground loops between the high- and low- voltage circuits and helping protect human operators from high voltages.

Figure 2-1 AC-input electric motor-drive block diagram

Figure 2-1 AC-input electric motor-drive block diagram