SSZTD45 July 2024 TPSM64406 , TPSM81033 , TPSM82813 , TPSM82816 , TPSM828303 , TPSM82866A , TPSM82866C , TPSM83102 , UCC33411-Q1

When designing the power stage of a system, you can choose from a variety of devices, such as low-dropout regulators (LDOs) or switching regulators, to regulate the voltage from a power source. While switching regulators are suitable when a system needs to maintain efficiency without exceeding certain ambient temperatures, power modules take it a step further by integrating the required inductor or transformer within the switching regulator package.

Power modules can take many forms: embedded micro system in package (µSiP), leaded, quad flat no lead (QFN) or our new MagPack™ packaging technology. Each of these package types has specifications that optimize performance features such as efficiency, thermals, electromagnetic compatibility and solution size. In this article, we’ll spotlight some of the features of each package type and which application requirements they fulfill.

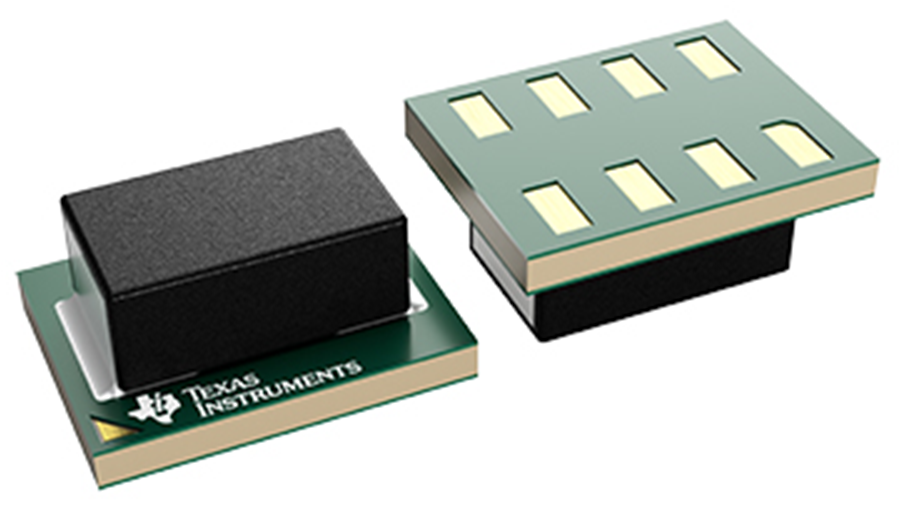

Embedded µSiP

Modules using µSiP packaging feature a converter integrated circuit (IC) embedded inside a substrate, with an inductor and a few passive components mounted on top. Since the converter IC does not take up any additional space when embedded in the substrate, modules that come in a µSiP package are useful for applications with limited board space. As shown in Figure 1, the TPSM83100 is a 5.5V, 1W buck-boost module that offers bidirectional current operation mode for backup solutions and comes in a 2.5mm by 2.0mm by 1.2mm µSiP package.

Figure 1 µSiP package drawing of

TPSM83100

Figure 1 µSiP package drawing of

TPSM83100 Leaded

Leaded packages include an IC in between two copper leadframes, with passive components placed on top. These packages are what most power designers are used to, making layout more intuitive. The visible leads make the package resilient, as it allows for high soldering integrity and easy debugging. This package type can ensure reliability by offering around 8mm of creepage clearance.

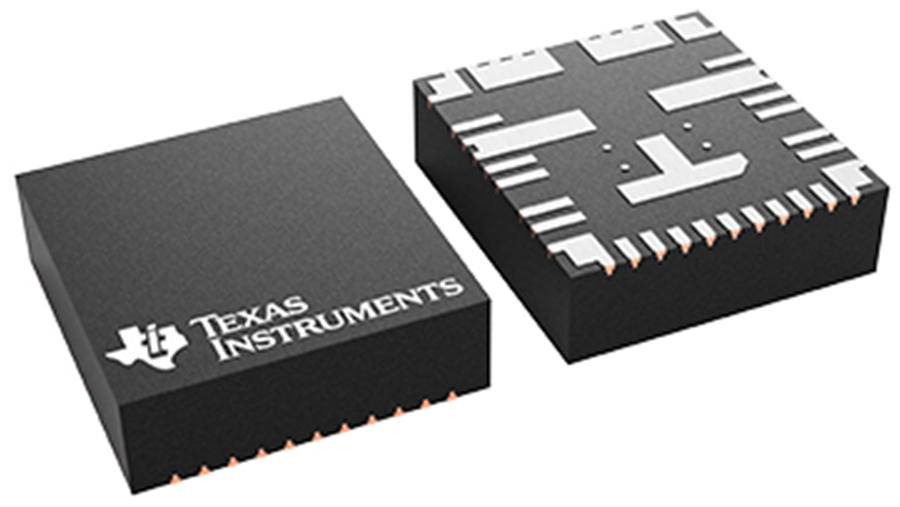

QFN

A QFN module is an umbrella term for packages that make connections to the board with flat pads instead of leads. QFN modules offer high power density and strong performance features that make them a well-rounded choice for many applications. There are two popular package configurations in the QFN module family: open-frame modules on a printed circuit board (PCB) substrate and overmolded modules on a leadframe.

Overmolded QFN packages are thermally enhanced plastic packages that use conventional copper leadframe technology. In the latest overmolded QFN modules from TI, such as the TPSM64406, as shown in Figure 2, placing the IC and passives directly on top of the leadframe enables improved electrical and thermal performance over traditional leaded packages. This 36V module offers dual 3A or a single stackable 6A output, and features symmetric high-frequency input bypass capacitors that are useful for noise-sensitive applications.

Figure 2 Overmolded QFN package drawing

of TPSM64406

Figure 2 Overmolded QFN package drawing

of TPSM64406The open-frame QFN module integrates switching and passive components onto a PCB substrate without overmolding them in a plastic casing. Skipping this step allows for better thermal dissipation by allowing designers to add a heat sink directly to the exposed inductor. Since open-frame packages have less of a size constraint and are less susceptible to overheating, they are rated at higher output currents than other module packages, which is beneficial for power-hungry applications such as enterprise computing.

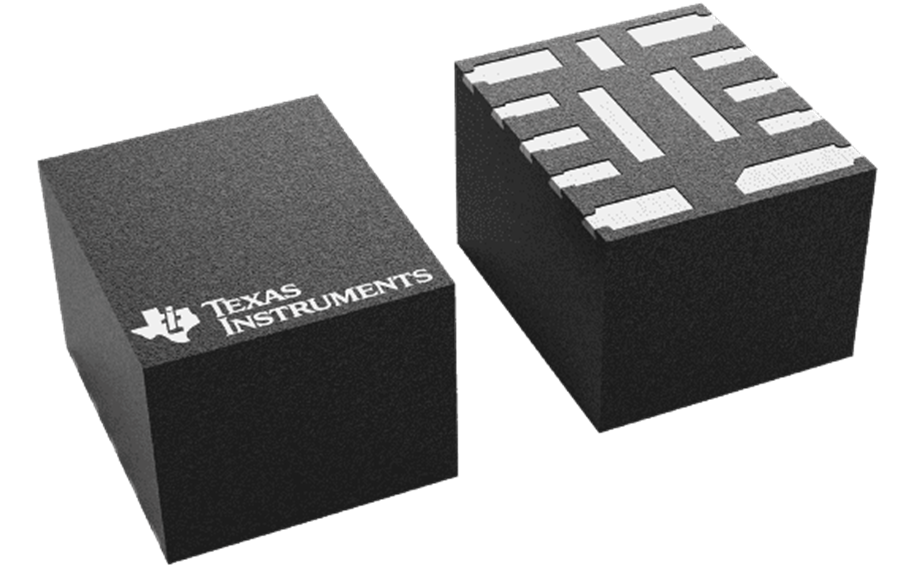

MagPack technology

MagPack packaging technology is TI’s latest power module package type. These modules leverage our proprietary, integrated magnetic packaging technology, removing reliance on third-party inductors. In addition to having higher power density than previous generations, these modules such as the TPSM82816 offer better thermal conductivity and less electromagnetic interference. To learn more about MagPack technology, read the technical article, “MagPack™ technology: Four benefits of new power modules that can help you pack more power in less space.”

Figure 3 MagPack package drawing of

TPSM82816

Figure 3 MagPack package drawing of

TPSM82816Conclusion

Power modules are a great option for power designers and provide many benefits over discrete solutions and LDOs given their multitude of performance features. They come in several package types that allow for optimization based on the application requirements.

Additional resources

- Read the application note, Soldering Considerations for Power Modules.

- Learn more about our Power modules (integrated inductor) portfolio.

Trademarks

All trademarks are the property of their respective owners.