SNOAA35F April 2019 – December 2024 LM2901 , LM2901B , LM2901B-Q1 , LM2903 , LM2903-Q1 , LM2903B , LM2903B-Q1 , LM339 , LM339-N , LM393 , LM393-N , LM393B , LM397 , TL331 , TL331-Q1 , TL331B

- 1

- Abstract

- Trademarks

- 1 Devices Covered in Application Note

- 2 The New TL331B, TL391B, LM339B, LM393B, LM2901B and LM2903B B Versions

- 3 PCN's to Change Classic Die to a New Die Design

- 4 Changes to Package Top Markings

- 5 Roughened Leadframe Finish

-

6 Input Considerations

- 6.1 Input Stage Schematic – The Classic LM339 Family

- 6.2 Input Stage Schematic - New "B" and TiB Devices

- 6.3 Differences Between the Classic, "B" and Tib Die Devices

- 6.4 Input Voltage Range

- 6.5 Input Voltage Range vs. Common Mode Voltage Range

- 6.6 Reason for Input Range Headroom Limitation

- 6.7 Input Voltage Range Feature

- 6.8 Both Inputs Above Input Range Behavior

- 6.9 Negative Input Voltages

- 6.10 Power-Up Behavior

- 6.11 Capacitors and Hysteresis

- 6.12 Output to Input Cross-Talk

- 7 Output Stage Considerations

- 8 Power Supply Considerations

- 9 General Comparator Usage

- 10PSpice and TINA TI Models

- 11Conclusion

- 12Related Documentation

- 13Revision History

5 Roughened Leadframe Finish

Texas Instruments is implementing a new single-side roughened leadframe. These leadframes are etched prior to plating to purposely roughen the lead surface. Roughening improves the solder adhesion (solderability) of the leads.

This roughening can make the leads look tarnished, corroded, or take on a gray or greenish appearance compared to the traditional smooth plated leadframes.

Figure 5-1 Classic (Shiny) Leadframe

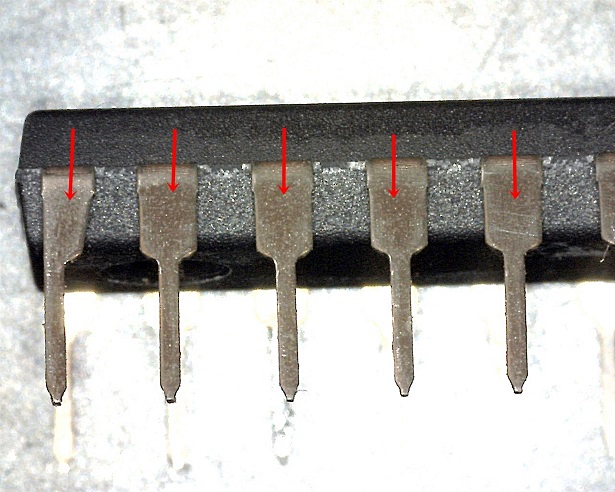

Figure 5-1 Classic (Shiny) Leadframe Figure 5-2 Roughened (Tarnished) Leadframe

Figure 5-2 Roughened (Tarnished) LeadframeThe darker or "tarnished" appearance is due to refraction of light on the rough surface as opposed to the traditional "shiny" mirror-like smooth plating. The light color and spectral purity can influence the appearance. Figure 5-2 shows a rather extreme close-up example of a roughened leadframe.

While the DIP package is shown as an example, the roughening is occurring across multiple package families (SC-70, SOT-23, SOIC, SOP, MSOP, VSSOP, TSSOP, as well as leadless packages).

The roughened leadframes go through the same plating process as the smooth leadframes and have passed or exceeded all the required JEDEC and AEC package qualifications. These roughened leadframes are being adopted across TI products and are not just exclusive to the LM339 family.