-

Getting Started With TI DLP® Display Technology DLPA059H January 2015 – April 2024 DLP160AP , DLP160CP , DLP2000 , DLP2010 , DLP230NP , DLP3010 , DLP3310 , DLP470NE , DLP470TE , DLP4710 , DLP471NE , DLP471TE , DLP471TP , DLP472NE , DLP472TE , DLP480RE , DLP550HE , DLP550JE , DLP650LE , DLP650NE , DLP650TE , DLP651LE , DLP651NE , DLP660TE , DLP670RE , DLP780NE , DLP780TE , DLP781NE , DLP781TE , DLP800RE , DLP801RE , DLP801XE , DLPA1000 , DLPA2000 , DLPA2005 , DLPA3000 , DLPA3005 , DLPC2607 , DLPC3420 , DLPC3421 , DLPC3430 , DLPC3433 , DLPC3435 , DLPC3438 , DLPC3439 , DLPC6401 , DLPC6540

-

Getting Started With TI DLP® Display Technology

- 1

- Abstract

- Trademarks

- 1 Introduction

- 2 DLP Display Projection Benefits

- 3 What is DLP Technology?

- 4 The DLP Display System

- 5 Selecting the Correct DLP Display Chipset

- 6 How to Evaluate Selected DLP Display Chipset

- 7 Selecting the Correct Optical Engine

- 8 DLP Products Supply Chain

- 9 Development and Manufacturing

- 10Online Resources

- 11Common Display and Projection Terminology

- 12References

- 13Revision History

- IMPORTANT NOTICE

Getting Started With TI DLP® Display Technology

Abstract

This application note is a comprehensive quick guide to find important resources for DLP® display products intended for industrial, enterprise, or personal electronics applications. This document serves as a starting guide for DLP chipset selection, evaluation, design, and manufacturing. You can benefit from this document regardless of your experience level and involvement with a DLP display system. You can send feedback or comments on this document using TI DLP Products E2E support forum.

The maturity of the design and manufacturing ecosystem for DLP display technology allows developers to take display application concepts to production quickly as illustrated below.

Interested in DLP technology outside of industrial, enterprise, and personal electronics display applications? Click here for DLP automotive applications and click here for Light Control applications using DLP technology, such as 3D print, 3D machine vision, and 3D scanning.

Trademarks

LightCrafter™, DLP IntelliBright™, and DLP Composer™ are trademarks of Texas Instruments.

DLP® is a registered trademark of Texas Instruments.

All trademarks are the property of their respective owners.

1 Introduction

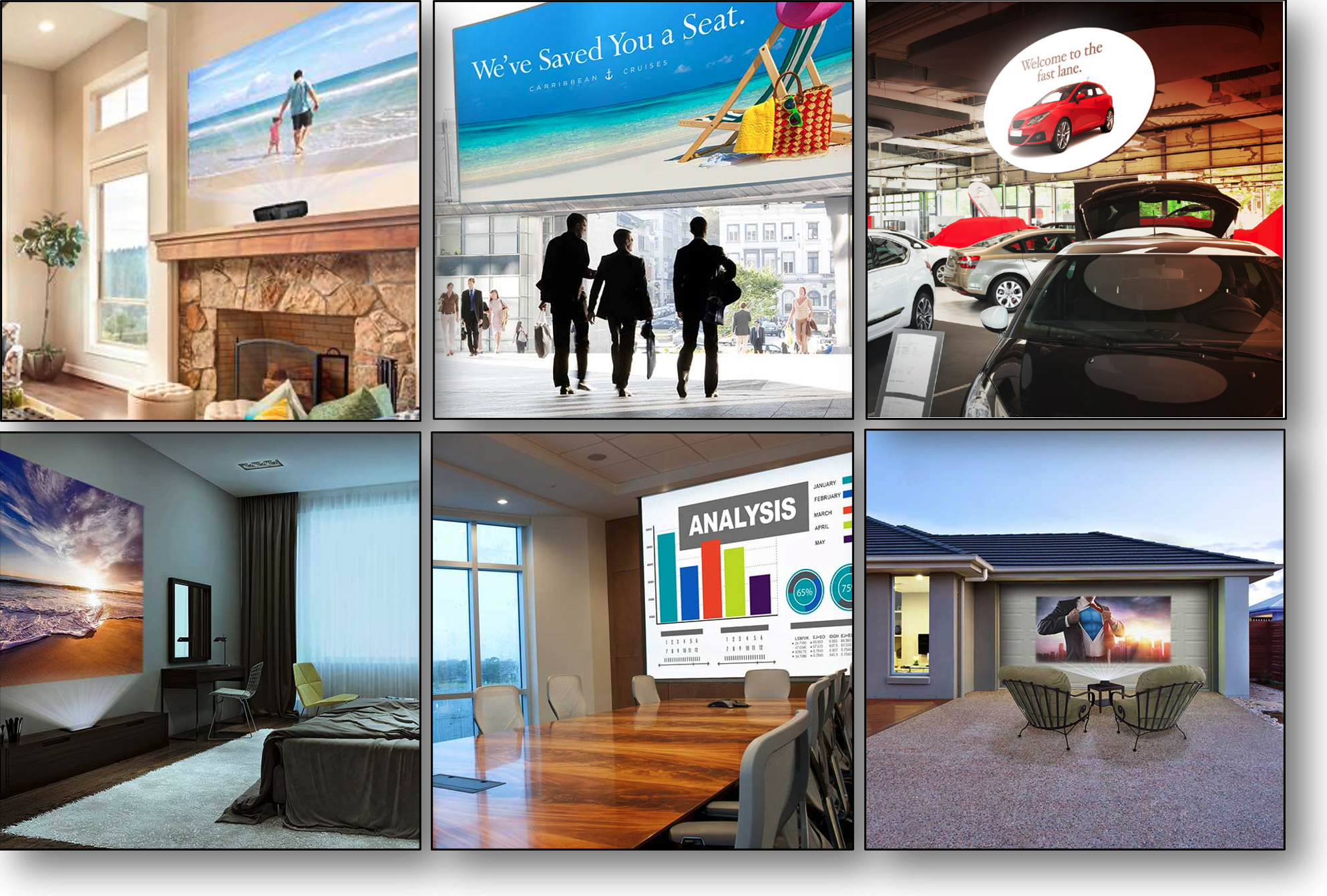

DLP® display products are used in a wide range of traditional accessory projectors and emerging display equipment. These include embedded projectors in smart phones and tablets, interactive surface computing, screenless and laser TVs, augmented reality glasses, digital signage, projection mapping, large venue, and cinema. DLP display technology contains two families of products, DLP Pico™ chipsets and DLP Standard chipsets. DLP Pico chipsets offer versatile display capability and can create images on virtually any surface from ultramobile devices. They are a good fit for any application requiring a display with high contrast, small size, and low power. DLP Standard chipsets enable amazing images for systems that require large screen bright displays with high resolution.

To help you navigate through this document, a Table 1-1 is provided to assist in prioritizing the sections that you might be interested in.

| I am... | Electrical Engineer | Optical Engineer | Software Engineer | Systems Engineer | Portfolio Manager |

|---|---|---|---|---|---|

| New to DLP technology | |||||

| Selecting a DLP chipset | |||||

| Evaluating a DLP chipset | |||||

| Development and Manufacturing | |||||

As you move along with your display application development, see the Table 1-1. For a quick reference guide on DLP Pico technology, see Getting Started with DLP Pico technology.

2 DLP Display Projection Benefits

Table 2-1 shows the main benefits that DLP projection enables for virtually any display application.

| Benefit | Description | |

|---|---|---|

| Excellent image quality |  |

Based on the same display technology used in 9 out of 10 cinemas worldwide (Based on PMA Research), the DLP chipset can enable a display that offers saturated colors and high contrast. Display system performance can vary depending on the optical engine. |

| Highcontrast ratio |  |

The reflective technology of DLP technology allows for high contrast as off state mirrors reflect light away from the projection optics creating very black pixels on the display surface. |

| Free form display |  |

Given its projection nature and high contrast ratio, one can enable a display with virtually any form factor. Black pixels will not show on the display surface (effectively providing a transparent background in those areas). |

| Display on virtually any surface |  |

Projection will display on virtually any surface. Warping can be used to geometrically compensate for irregular-shaped display surfaces. |

| Small size, large image |  |

The DLP technology optical architecture and pixel design allows for extremely small-form factors compared to the image displayed. |

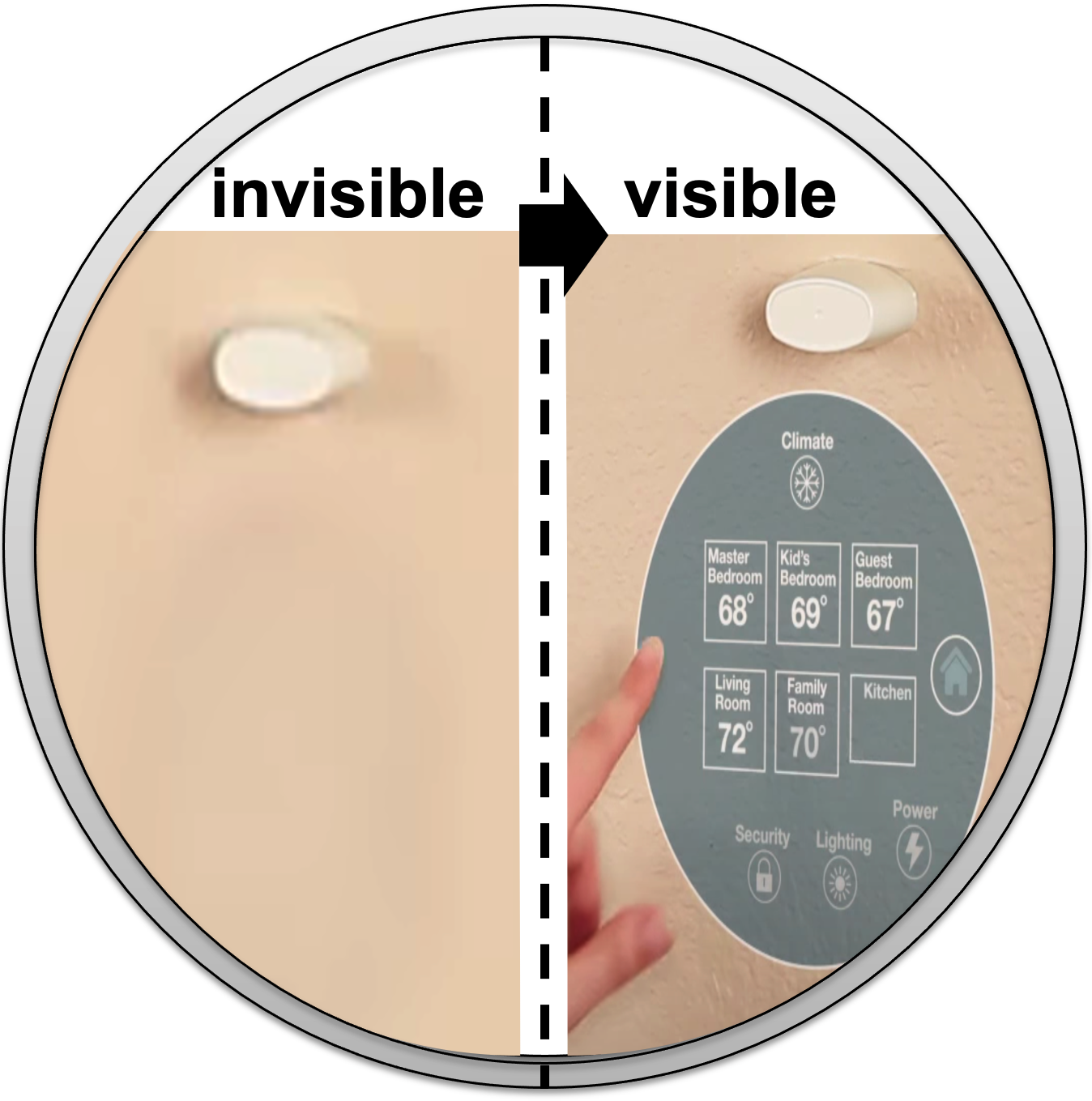

| Only visible when needed |  |

DLP projection display can be turned on and off on demand. The display disappears when it is turned off. |

Customers can learn how to promote features enabled by DLP technology by visiting the DLP Products Messaging and Icons Guidelines document (requires a myTI login).

DLP technology benefits outlined by application when visiting the web sites shown in Table 2-2.

| Website | Application Examples |

|---|---|

| Applications for DLP Pico chipsets | Pico projector, Enterprise portable

projector, Laser TV <85", smart home displays, industrial displays (DLP signage,

humanoids, commercial gaming), virtual reality/augmented reality glasses,

smartphones and tablets (mobile accessories), and more.

|

| Applications for DLP Standard chipsets | Laser TV > 85", smart projector,

digital signage, enterprise projector, large venue, and cinema.

|